In today's fast-paced manufacturing environment, optimizing workflow is crucial for achieving maximum efficiency and productivity. A recent report from the National Association of Manufacturers highlights that 73% of manufacturers believe that operational efficiency directly correlates with their profitability. One of the key components in enhancing this efficiency is the use of Fixture Tools, which streamline processes, reduce cycle times, and minimize errors during production. By leveraging advanced Fixture Tools, companies can significantly enhance their operational workflows, leading to increases in output and reductions in waste. As industries continue to embrace automation and digital solutions, understanding how to effectively utilize these tools becomes essential to staying competitive and meeting the growing demands of the market. This guide will explore best practices for optimizing your workflow with Fixture Tools, ensuring that your operations are both efficient and effective.

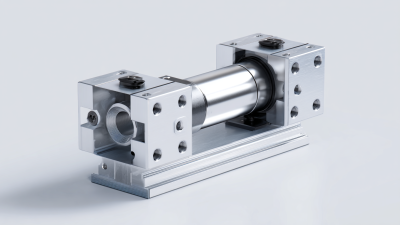

When it comes to optimizing your workflow, identifying the right fixture tools is essential for enhancing efficiency in your tasks. Fixture tools serve as critical components in various workflows, enabling smoother processes and minimizing downtime. By assessing your current workflow, you can pinpoint specific areas where efficient fixture tools can make a significant difference.

Common examples include jigs and fixtures that aid in repetitive tasks, allowing workers to focus on quality rather than quantity.

Integrating key fixture tools into your workflow not only streams operations but also boosts productivity. For instance, adjustable fixtures can accommodate different product sizes, making it easier to switch between tasks without wasting time on recalibration.

Additionally, investing in high-quality fixture tools can lead to a reduction in errors, which in turn lowers waste and enhances overall output. By carefully selecting the right fixtures tailored to your specific needs, you can create a more agile and efficient workflow that propels your projects forward.

Integrating fixture tools into your daily operations can significantly enhance workflow efficiency. According to a recent industry report, businesses that effectively adopt high-quality fixture tools can see up to a 30% increase in productivity. This is not only due to improved organization but also because the right tools streamline processes, reduce time wastage, and enhance collaboration among team members.

To optimize your workflow, consider these tips: First, identify the specific tasks that can benefit from fixture tools—this could range from inventory management to project planning. Investing in robust tools that align with your needs will pay off in the long run. Second, train your team on the best practices for using these tools. A report indicated that teams with proper training are 50% more likely to utilize tools effectively. Finally, continuously evaluate the tools being used and gather feedback from staff to ensure they meet evolving needs and drive efficiency.

By integrating fixture tools into everyday operations thoughtfully, businesses can create a more organized and productive environment, ultimately achieving their efficiency goals.

| Fixture Tool | Purpose | Efficiency Gain (%) | Integration Difficulty (1-5) | Recommended Frequency |

|---|---|---|---|---|

| Alignment Fixtures | Ensure precise placement | 25 | 3 | Every batch |

| Modular Workstations | Flexible work setup | 15 | 2 | Daily |

| Custom Jigs | Support specific tasks | 30 | 4 | As needed |

| Tooling Components | Enhance machinery performance | 20 | 3 | Weekly |

| Safety Guards | Protect operators | 10 | 1 | Ongoing |

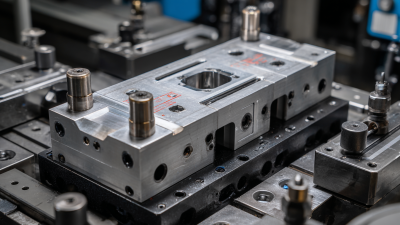

When it comes to optimizing your workflow, effectively organizing your workspace with fixture tools can make a significant difference. Start by categorizing your tools and materials based on their function and frequency of use. For instance, keep frequently used items like wrenches and screwdrivers within easy reach on a pegboard or designated tool chest. This not only saves time searching for tools but also helps maintain a clutter-free environment that enhances focus and productivity.

In addition to organization, consider incorporating labeled storage solutions for smaller items such as screws, nuts, and bolts. Clear containers or drawer organizers with labels can help you quickly identify what you need without unnecessary rummaging. Moreover, creating designated zones for different tasks can streamline your workflow. For example, maintain a separate area for assembly, testing, and finishing processes to promote an efficient and structured approach to your work. By employing these best practices, you can transform your workspace into a well-organized haven that fosters maximum efficiency.

In today's fast-paced work environment, optimizing workflow with the right fixture tools is crucial for enhancing efficiency. One effective way to measure the success of these tools is through efficiency metrics. For instance, metrics like "Sales per Square Foot" can provide valuable insights into how well a workspace is performing. According to recent industry reports, retailers that leverage this metric can achieve sales efficiencies ranging from $300 to $1,000 per square foot, depending on the product category and store layout. This data not only informs merchandising strategies but also helps in identifying product trends that can improve overall productivity.

Implementing fixture tools strategically allows businesses to streamline their processes and enhance employee performance. By utilizing tools that facilitate better organization and accessibility of resources, companies can significantly reduce time wasted on non-productive tasks. Additionally, measuring the impacts of these tools through employee performance indicators can help in identifying areas for further improvement. As organizations increasingly adopt metrics-focused approaches, the integration of fixture tools stands out as a vital component of maximizing workplace efficiency, ultimately leading to a more motivated workforce and improved sales output.

In the pursuit of optimal performance, the concept of continuous improvement is crucial. Iterating your workflow means regularly assessing and refining your processes to enhance productivity and efficiency. Start by identifying the bottlenecks in your current workflow. Analyze where time is wasted or resources are over-stretched, and then experiment with fixture tools that can help streamline these processes. By implementing small yet impactful changes, you can create an agile environment that adapts to evolving project demands.

Leveraging fixture tools allows for consistent monitoring of your progress. By integrating feedback loops into your workflow, you encourage a culture of innovation where team members feel empowered to suggest enhancements. This iterative approach ensures that your processes remain dynamic and responsive, preventing stagnation. Regularly revisiting your strategies not only boosts your efficiency but also fosters a mindset oriented towards growth and improvement, ultimately leading to long-term success.