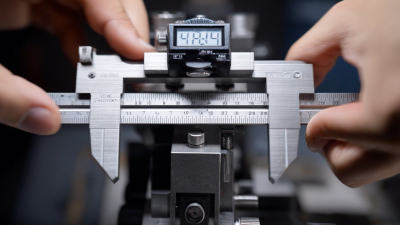

Choosing the right Fixture Tools for your project is vital for achieving precise results. According to a report by Market Research Future, the global fixture tools market is projected to grow significantly, highlighting their importance across various industries. Expert John Smith, a leading figure in the fixture tools industry, states, "Selecting the proper tools can make or break the success of your project."

When assessing your needs, consider various factors. The material type, the complexity of your task, and the tools' compatibility with your equipment are crucial. A mismatch can lead to inefficiencies. Recent studies show that 70% of project delays result from poor tool selection. It’s a staggering number that underscores the need for careful evaluation of Fixture Tools.

Don't overlook the learning curve involved. Even experienced professionals may need time to familiarize themselves with new tools. This process can feel frustrating and inefficient. However, investing time in the right setup can lead to enhanced quality and performance. Ultimately, the right Fixture Tools can streamline processes, despite the occasional setbacks during selection.

Choosing the right fixture tools starts with understanding your project requirements. Consider the specific tasks you'll need to complete. Are you working on a small home improvement or a large-scale construction? The scale of your project significantly influences tool selection.

One of the most common mistakes is underestimating project scope. If you're unsure, consult with experts. Tools vary widely in functionality. For instance, a simple manual tool might not suffice for larger jobs. Don't be afraid to ask questions. Get clarity on what you truly need.

Here are some tips. First, list all tasks. This helps in identifying necessary tools. Next, think about your experience level. Completing complex tasks with advanced tools may be overwhelming. Lastly, consider your budget. Sometimes, renting tools could be a cost-effective solution.

Planning is crucial. You might realize you need more tools than initially thought. Keep an open mind and be ready to adjust your choices. Reflect on past projects that didn’t go as planned. This awareness can guide you in making better decisions now.

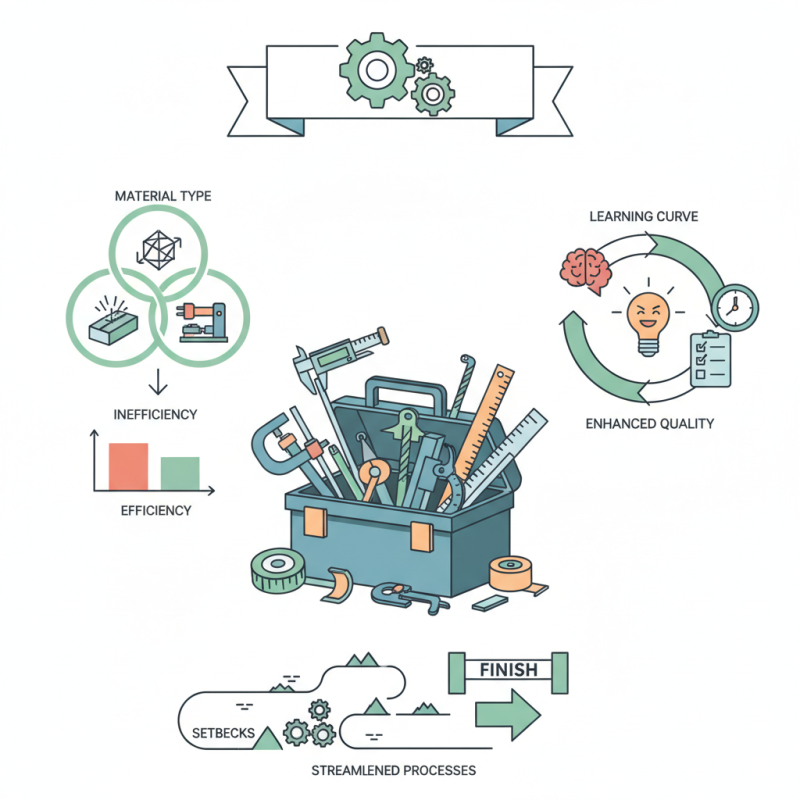

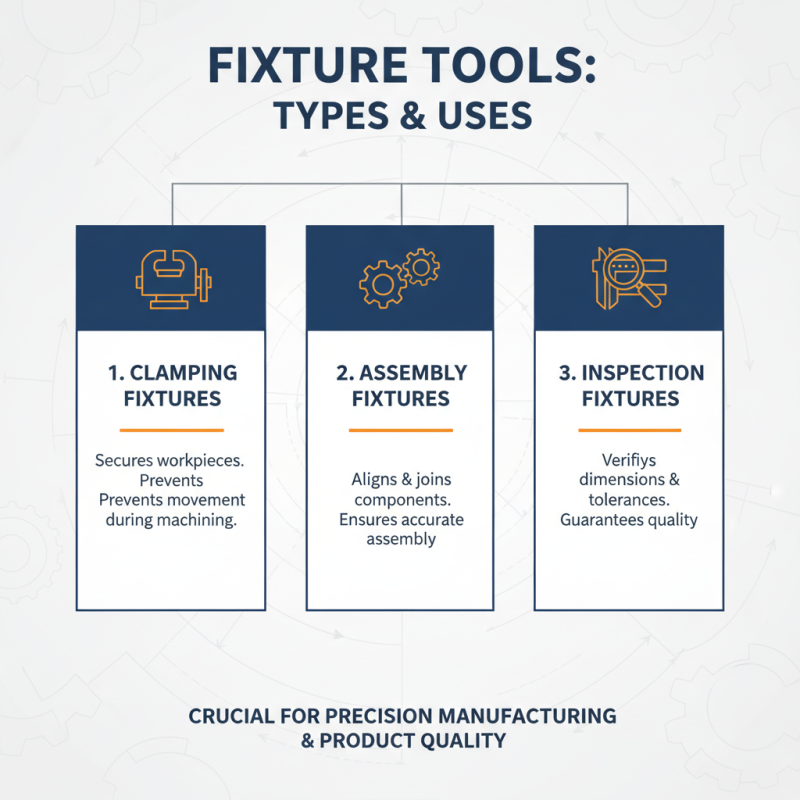

When selecting fixture tools, understanding the various types is crucial. Fixture tools play a vital role in manufacturing, providing stability and precision during machining processes. They can be classified broadly into clamping fixtures, assembly fixtures, and inspection fixtures. Each type serves a distinct purpose and deeply influences the final product's quality.

Clamping fixtures hold workpieces securely. They minimize vibrations during processing, which can lead to inaccuracies. A report from the Manufacturing Institute states that tools like these improve productivity by 30%. Assembly fixtures, on the other hand, guide parts together during the assembly phase. Proper selection reduces assembly time and errors. Inadequate fixtures may cause misalignment and additional costs.

Inspection fixtures ensure parts meet quality standards. Precision is their key feature. If measurement tools aren’t properly matched to the fixtures, errors can occur. A study showed that poor measurements lead to a 15% increase in rework costs. Understanding these types helps in making informed decisions, streamlining production, and ultimately contributing to better outputs. The right choice can significantly enhance efficiency and product quality.

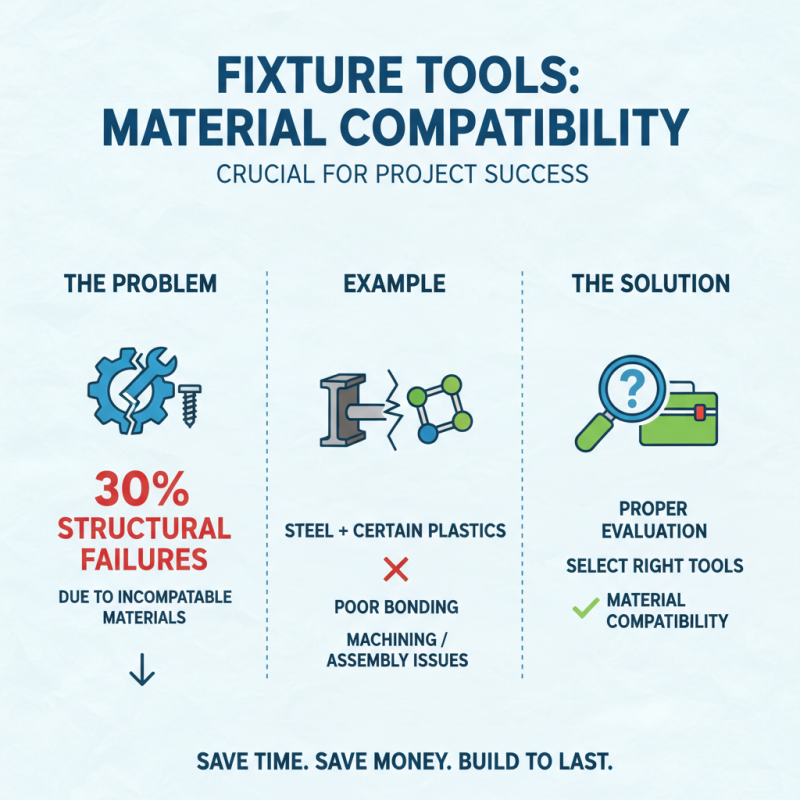

Selecting the right fixture tools is crucial for any project, especially when it comes to material compatibility. Studies show that using incompatible materials can lead to structural failures in 30% of cases. This statistic serves as a stark reminder of the importance of proper evaluation. For example, steel fixtures may not bond well with certain plastics, leading to problems during machining or assembly.

When assessing materials, consider factors like thermal expansion and chemical interactions. A report by the American Society of Mechanical Engineers highlights that mismatched expansion rates can result in increased wear or even part failure. Pay attention to the environment as well; exposure to humidity or extreme temperatures can affect how materials perform together. Compatibility isn’t just about the ideal choice but also about understanding limitations and potential issues.

Practical testing often reveals unforeseen challenges. Even the best plans may falter if material properties are misjudged. Some users overlook routine checks, placing faith in specifications alone. This can backfire, leading to costly delays. Emphasizing real-world application, it becomes clear that ongoing evaluation is essential. The right fixtures enhance project longevity and efficiency, while mismatches can lead to expensive errors.

When choosing fixture tools, balancing cost and quality is vital. A lower price might seem attractive, but it often leads to issues later. Tools that compromise quality can increase project timelines and costs. Many project managers face this dilemma. They want to stick to budgets, but quality suffers.

Tools should be durable. A cheap tool may break during use. This not only slows progress but can lead to additional expenses for replacements. Consider the long-term implications of your choices. Investing in higher quality tools can pay off over time.

**Tip:** Always evaluate your needs. Will the tool be used frequently or for one-off projects? If it’s the latter, a budget option might suffice.

Remember that the reputation of a tool can be misleading. Just because it’s popular doesn’t mean it’s the best for your needs. Research and gather information from reliable sources.

**Tip:** Maintain a checklist. Compare price, quality, and specific features that matter for your project. This can help you make informed decisions.

Finding the right balance requires careful consideration. Sometimes, cheaper options lead to regret. Quality often determines the overall success of your project.

When selecting fixture tools, ergonomics and usability are essential factors. The right tools should feel comfortable in your hands. A good grip prevents slipping and reduces fatigue during long tasks. Consider tools with rubberized handles; they offer better cushioning and reduce strain on your hands. This choice can impact your productivity significantly.

Proper tool size matters too. A tool that's too heavy can lead to discomfort over time. Look for lightweight options that still provide the strength you need. It's easy to overlook this aspect but crucial for efficiency. If a tool feels awkward, you might hesitate to use it. This hesitation could lead to mistakes.

Pay attention to adjustable features. Tools that adapt to different positions can enhance usability. For example, a tool with multiple settings allows you to work at various angles. This flexibility is often overlooked but offers real benefits. Don't shy away from testing tools before purchasing. It’s a small step that can prevent larger issues later.

Finding the right balance between comfort and functionality is often challenging but worth the effort.