The Importance of Well-Designed Inspection Fixture Covers

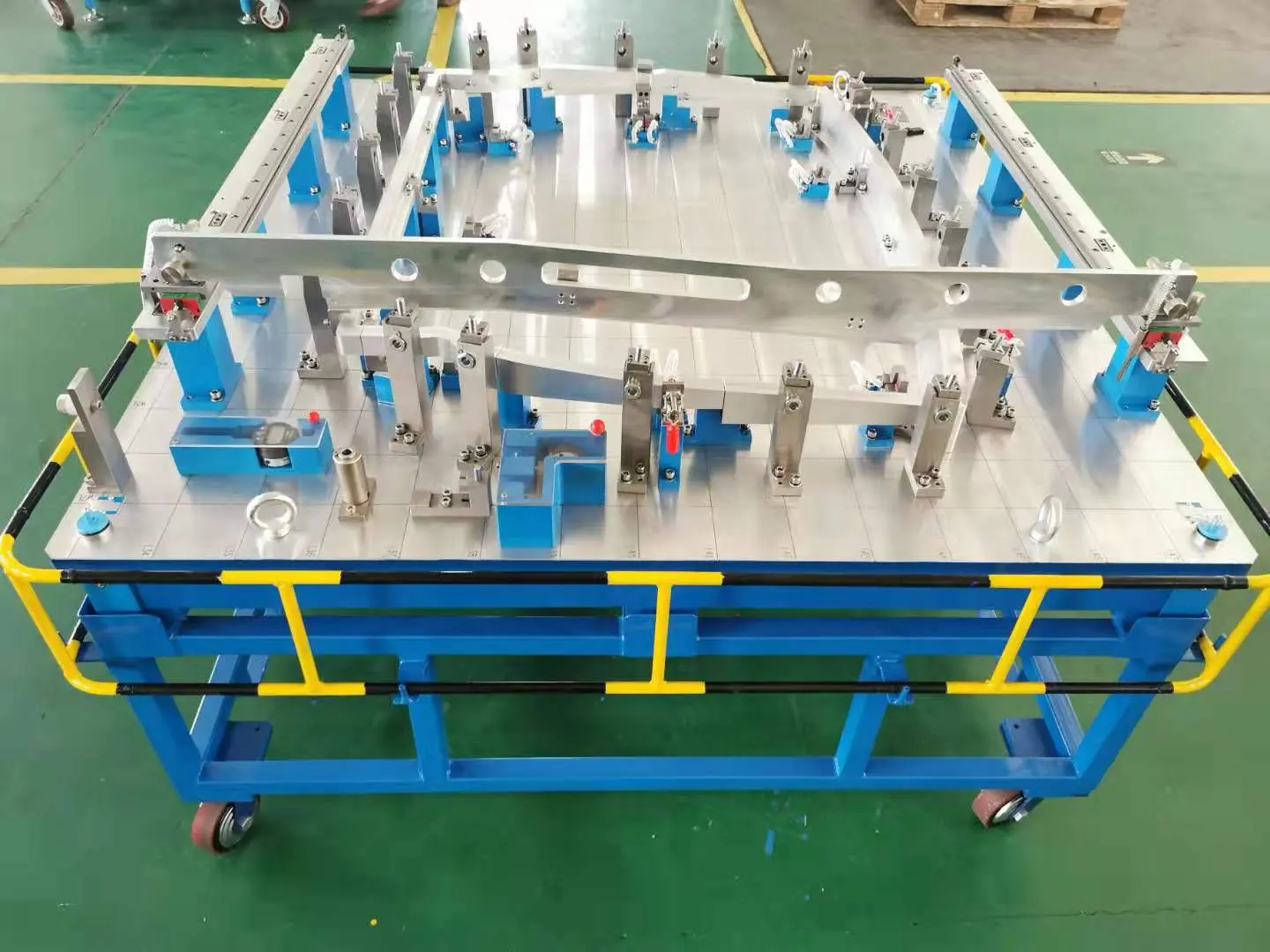

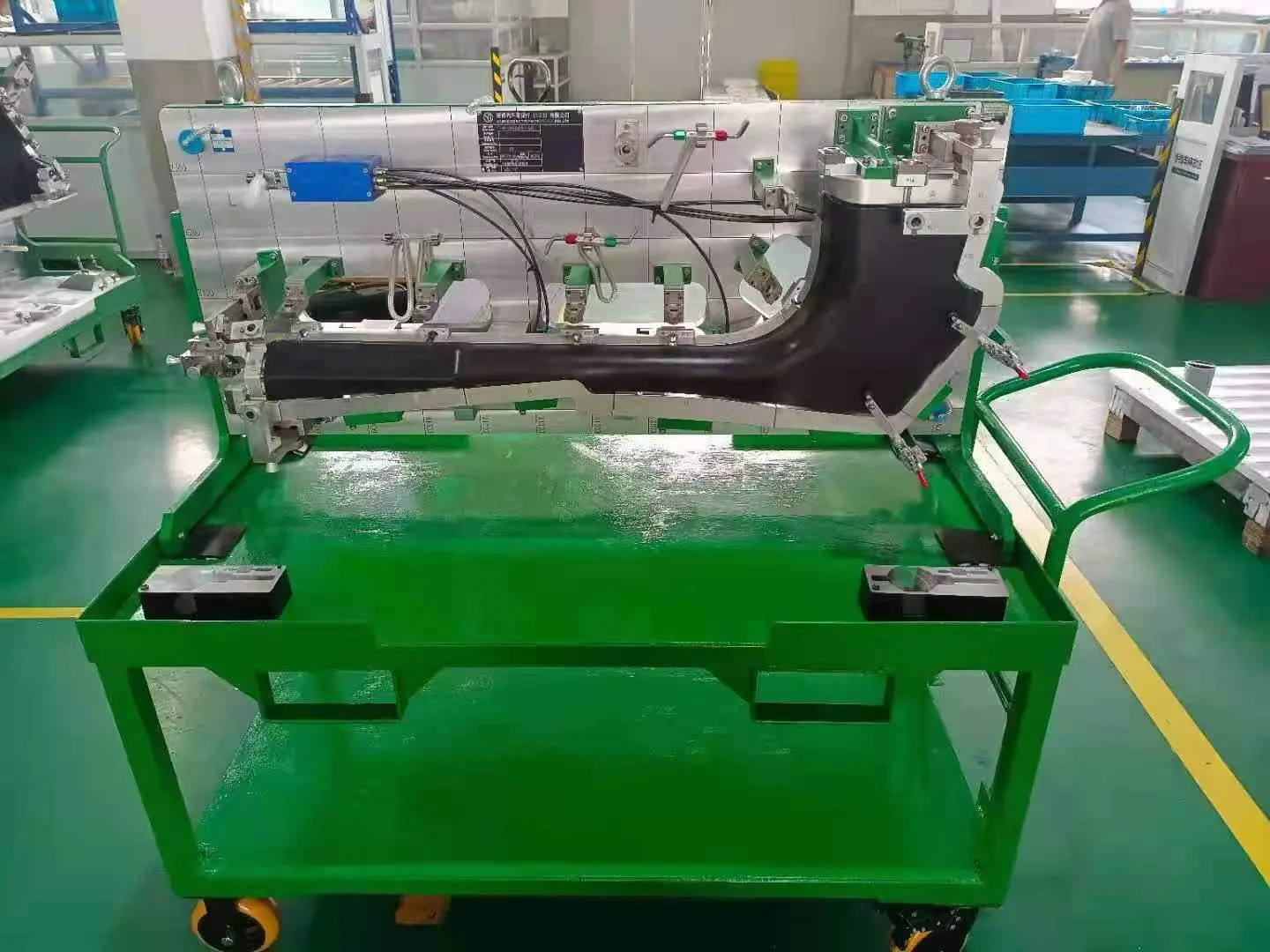

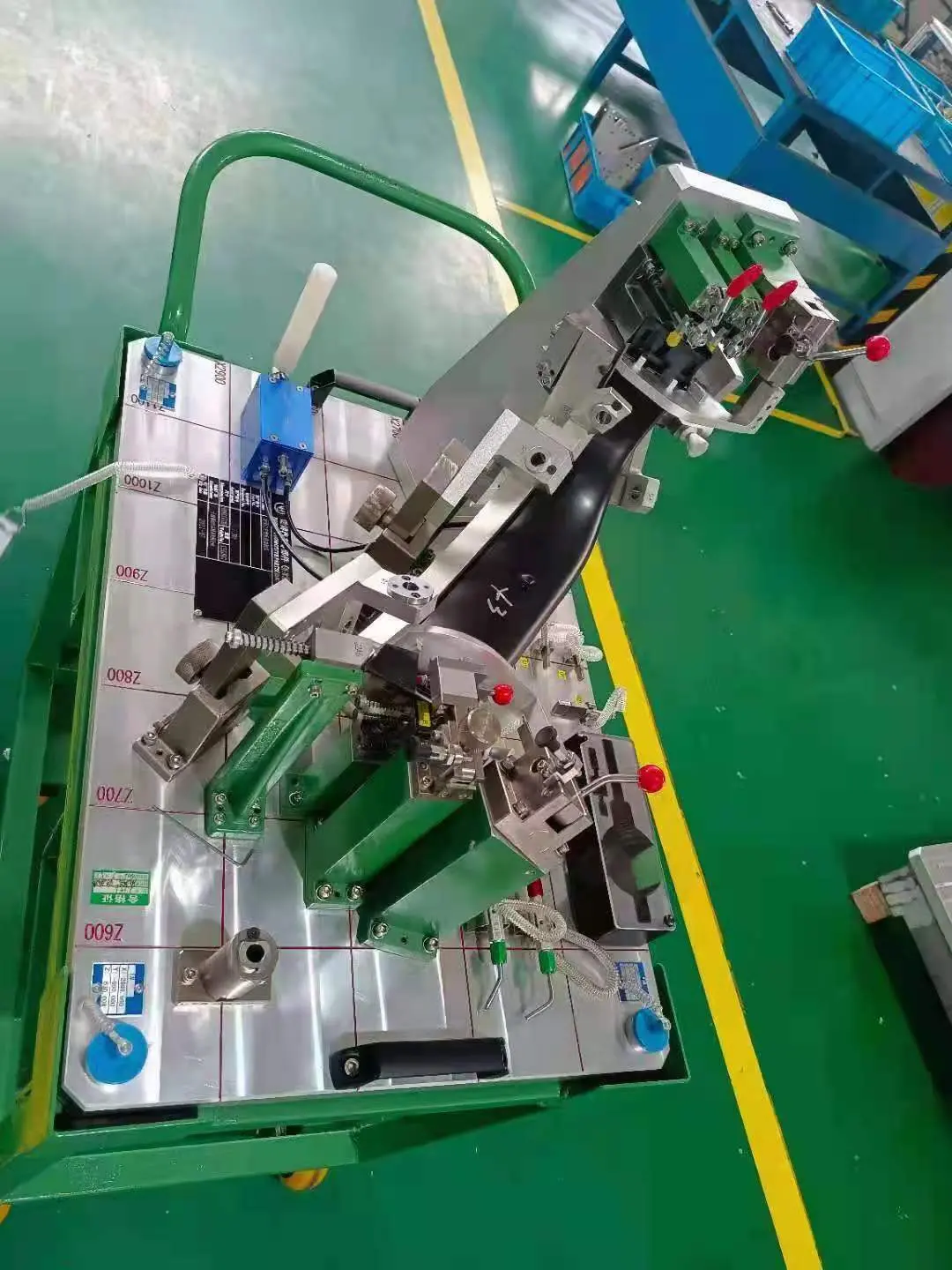

First and foremost, the gage cover acts as a protective cover for the gage and is used to verify the accuracy and quality of manufactured parts. The cover helps prevent any external components from contaminating the fixture, which could lead to inaccurate measurements and part failure. By protecting the fixture, the cover ensures that the measurements taken are reliable and consistent, ultimately helping to improve the overall quality of the production process.

Additionally, well-designed inspection fixture covers are critical to ensuring the safety of operators and technicians using the fixture. The cover acts as a barrier to prevent accidental contact with the fixture's delicate components, which could result in damage or injury. By providing a safe and enclosed environment, covers enhance the safety of the working environment, reduce the risk of accidents and ensure the well-being of those involved in the manufacturing process.

Inspection fixture covers In addition to their protective function, they also play an important role in keeping the fixture clean and hygienic. By sealing the fixture from external contaminants such as dust, dirt and debris, the cover helps maintain the integrity of the measurement surface and sensitive components. This is particularly important in industries where cleanliness and precision are critical, such as automotive manufacturing and aerospace engineering, where even the smallest particles can have a significant impact on the quality of the final product.

Additionally, well-designed inspection fixture covers help improve the overall efficiency and productivity of the manufacturing process. By providing a safe and controlled environment for the fixture, covers minimize the risk of errors and inaccuracies, resulting in faster, more reliable measurements. This in turn leads to a more streamlined production process, reducing the need for rework and ensuring parts meet required specifications in a timely manner.

To sum up, the inspection tool cover is an essential part of the manufacturing process and plays a vital role in ensuring the accuracy, safety, cleanliness and efficiency of the production process. Well-designed inspection fixture covers not only protect the fixture and the part being produced, but also help improve the overall quality and reliability of the manufacturing process. Therefore, manufacturers must invest in high-quality, well-designed inspection fixture covers to ensure the success and competitiveness of their operations.