The Importance of Checking the Fixture Tank for Smooth Operation

The inspection tool oil tank is a key component in machinery that is often overlooked. It acts as an oil reservoir, which is essential for lubricating moving parts and reducing friction within the equipment. Without proper lubrication, wear and tear on machinery can increase, leading to reduced efficiency and potential failure. Regularly checking the oil level and quality within the clamp tank is essential to prevent these problems and ensure the smooth operation of the machinery.

In addition to maintaining proper lubrication, the inspection tool oil tank also plays a role in regulating the internal temperature of the machinery. Oil helps dissipate the heat generated by moving parts, preventing equipment from overheating and potential damage. By monitoring oil level and quality, operators can ensure machinery remains within optimal temperature ranges, extending service life and improving performance reliability.

In addition, the inspection tool oil tank is crucial to prevent internal corrosion and rust of the machinery. The oil acts as a protective barrier, preventing metal parts from coming into contact with moisture and oxygen, which can cause corrosion over time. Regular inspection and maintenance of your oil tank can help detect any signs of corrosion early, allowing timely intervention and preventing costly damage to your equipment.

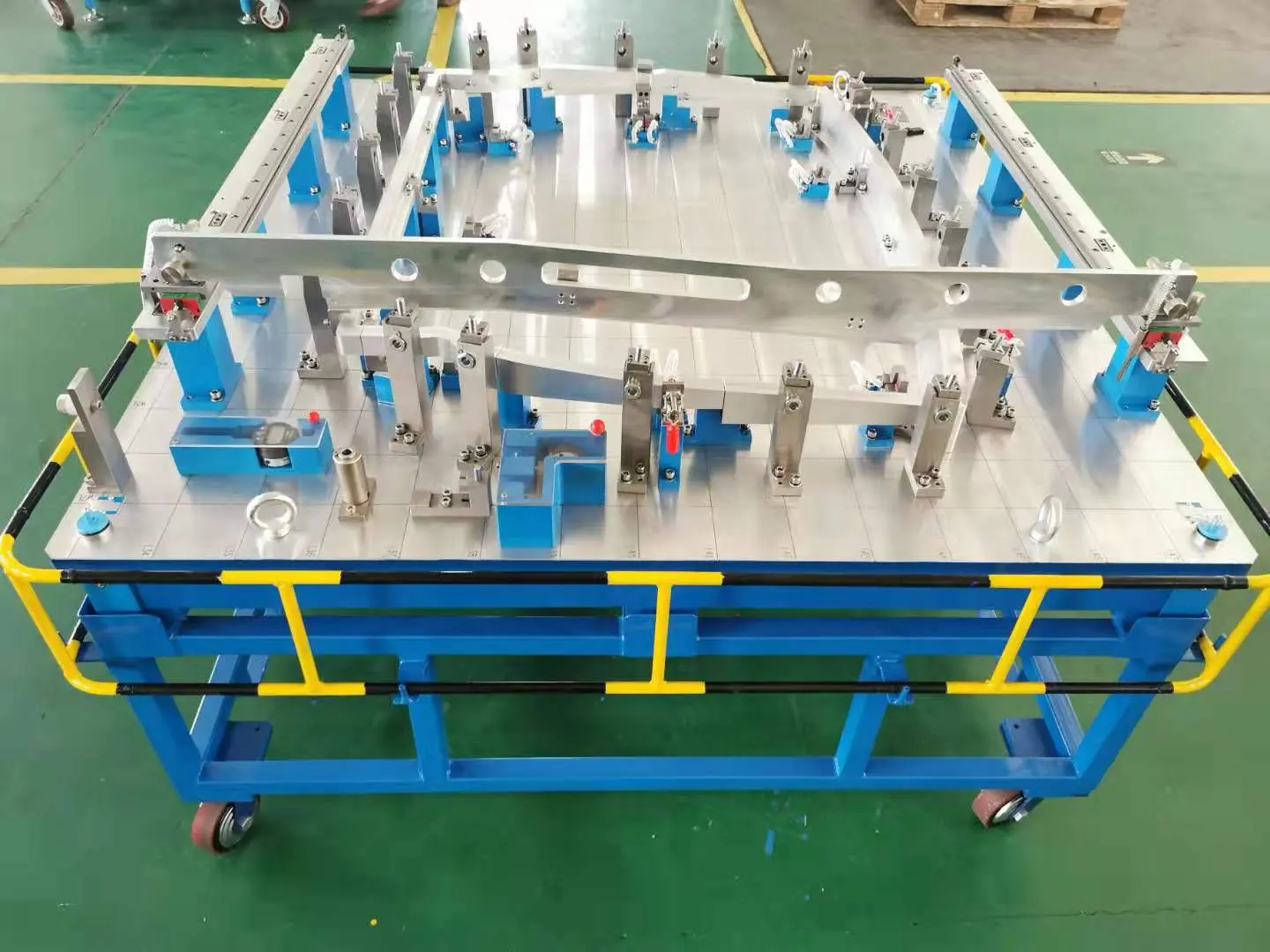

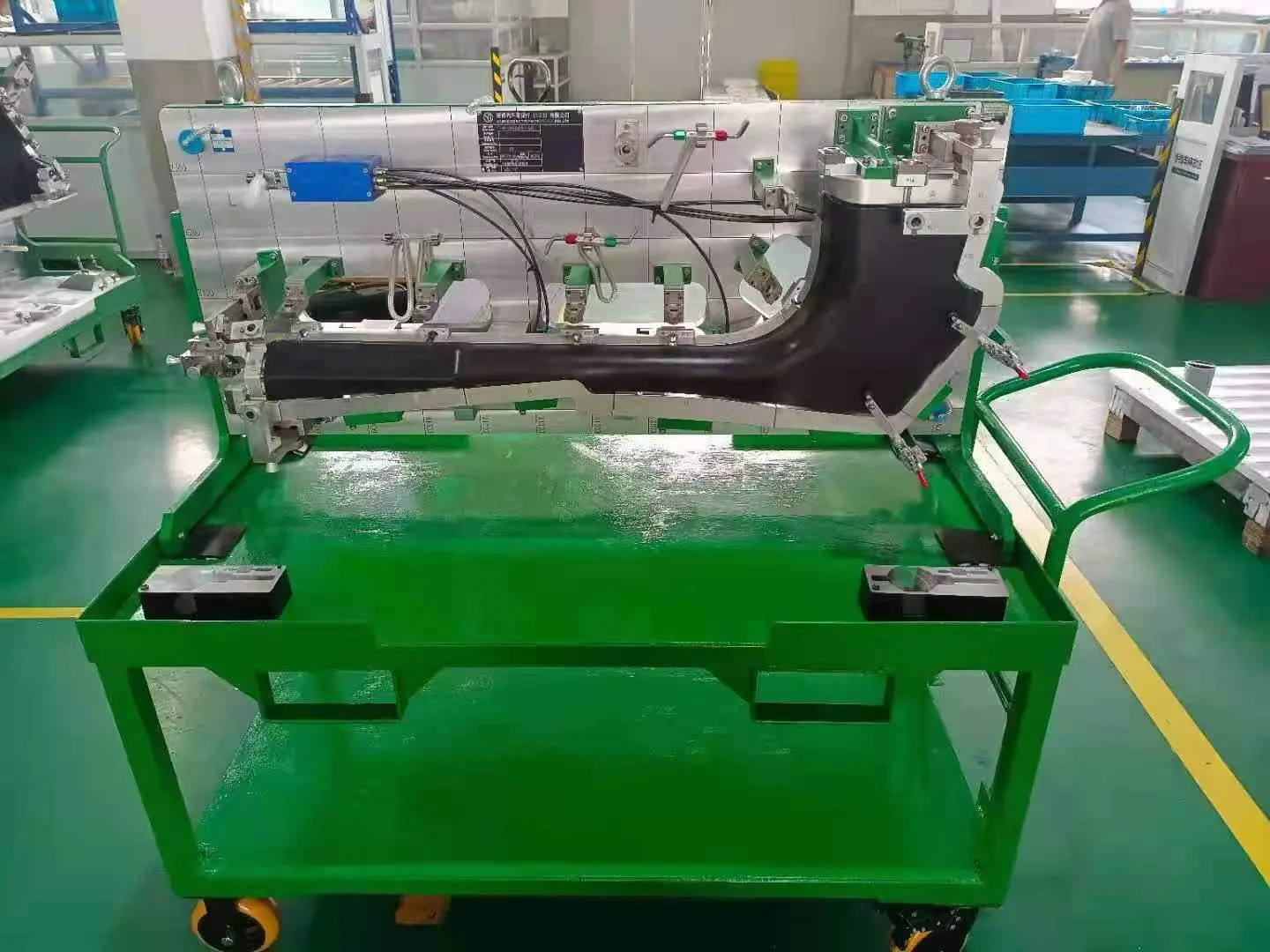

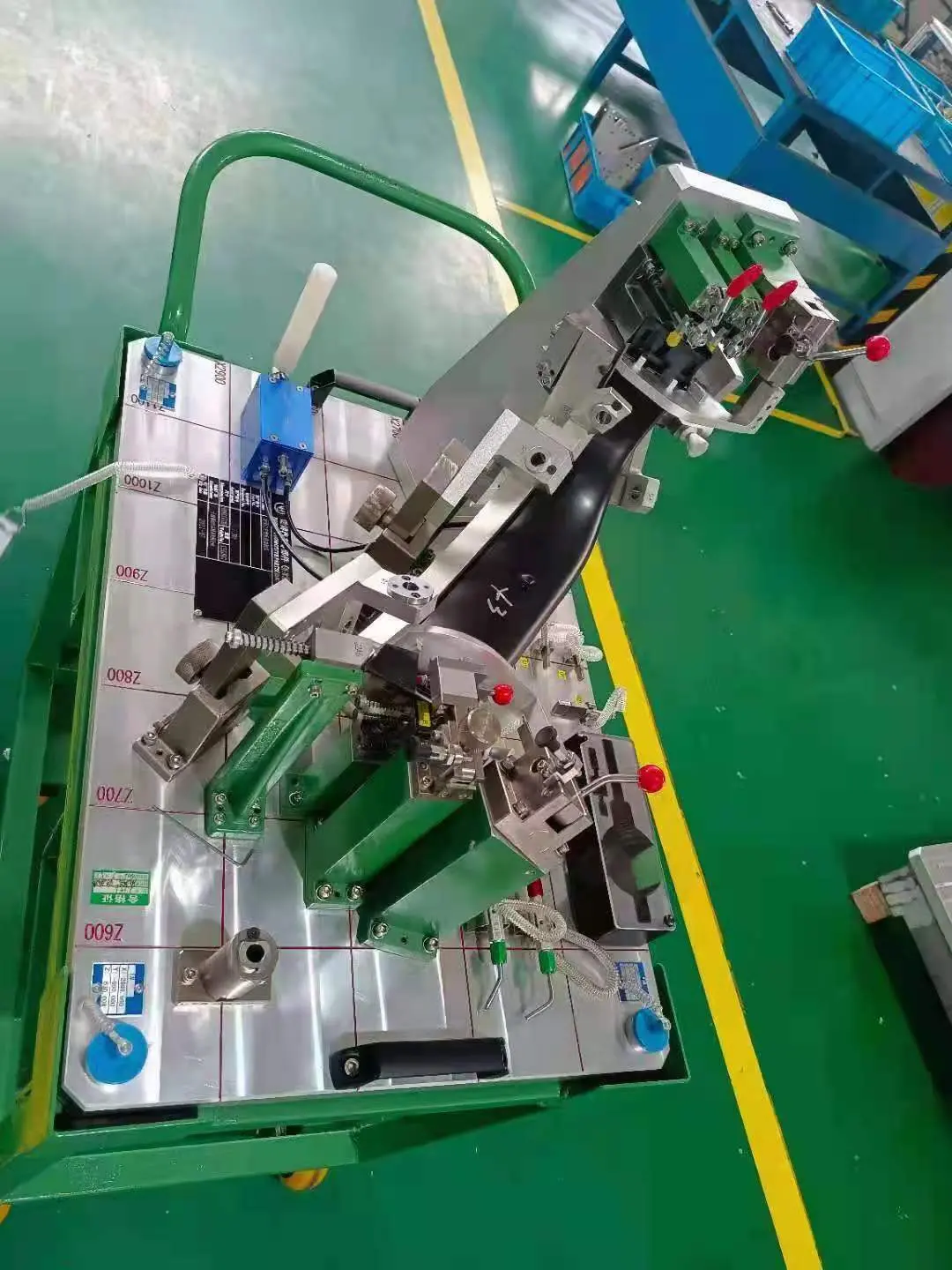

In the automotive industry, gage tanks are particularly important to ensure the accuracy and precision of measuring fixtures used in the manufacturing process. These fixtures are used to verify the quality and dimensions of automotive parts, and any deviation in their performance can lead to costly errors in production. By maintaining proper oil levels and quality in the jig reservoir, manufacturers can ensure the reliability and accuracy of these critical tools, ultimately contributing to the overall quality of the finished product.

In short, the inspection tool oil tank is a small but essential component, which plays an important role in the smooth operation and service life of the machinery. Regular inspection and maintenance of oil level and quality are critical to ensuring proper lubrication, temperature regulation and corrosion protection within the equipment. Whether it's industrial machinery or automotive fixtures, fixture fuel tanks are a key factor in maintaining efficiency and reliability. By prioritizing the care and maintenance of this often-overlooked component, operators can contribute to the overall performance and longevity of their machines.