The growing popularity of custom vehicle inspection tools in the automotive industry

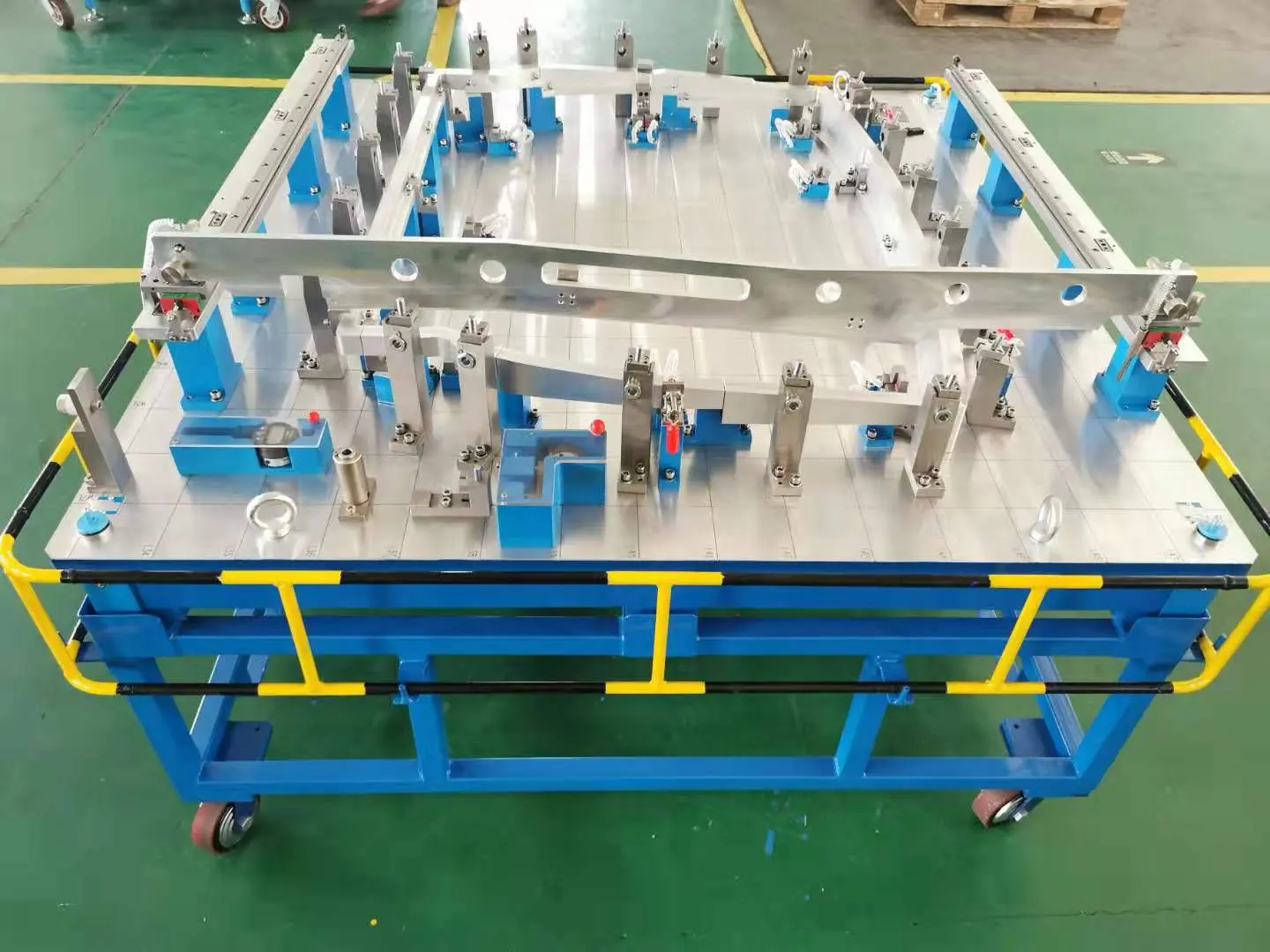

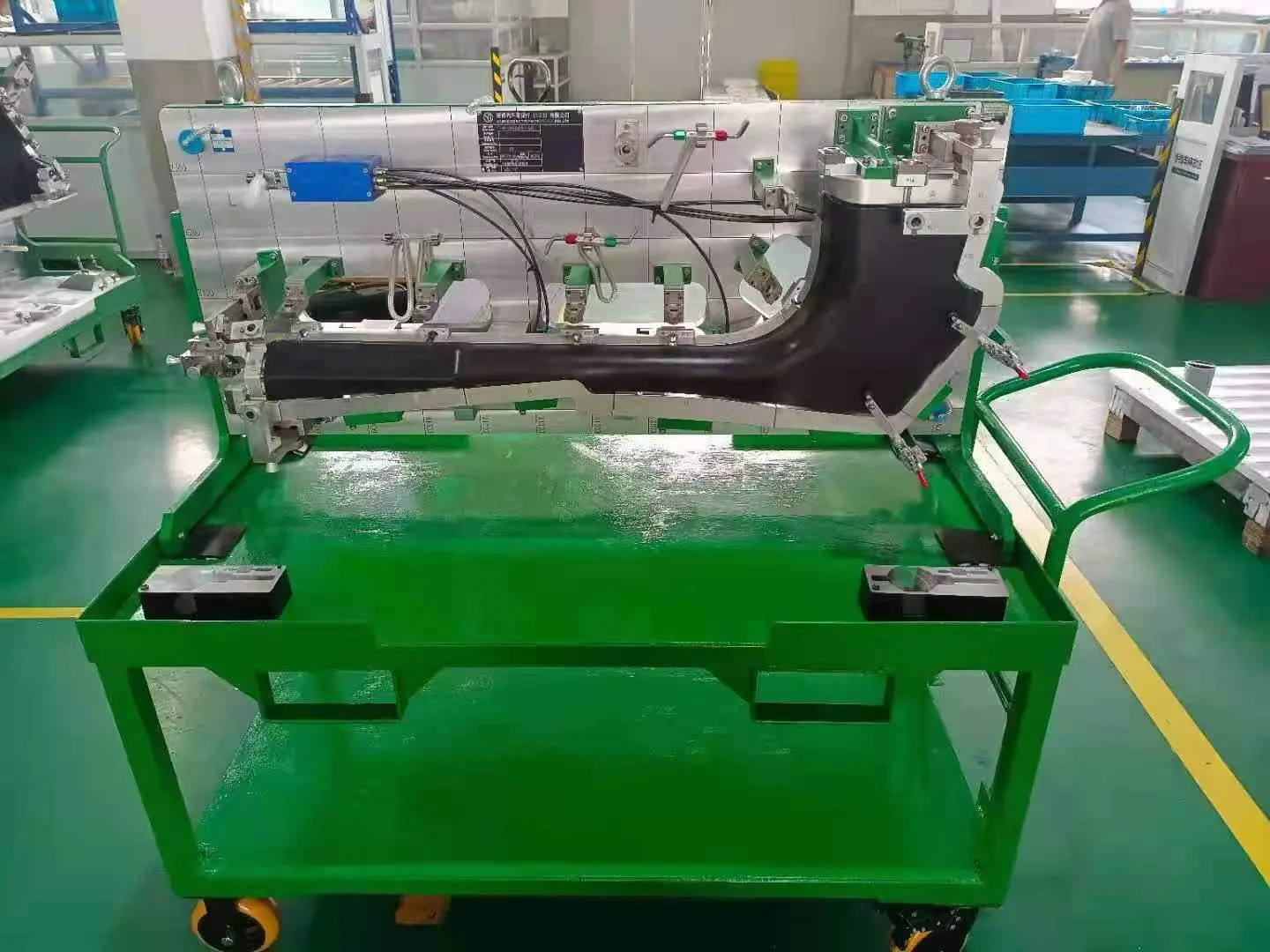

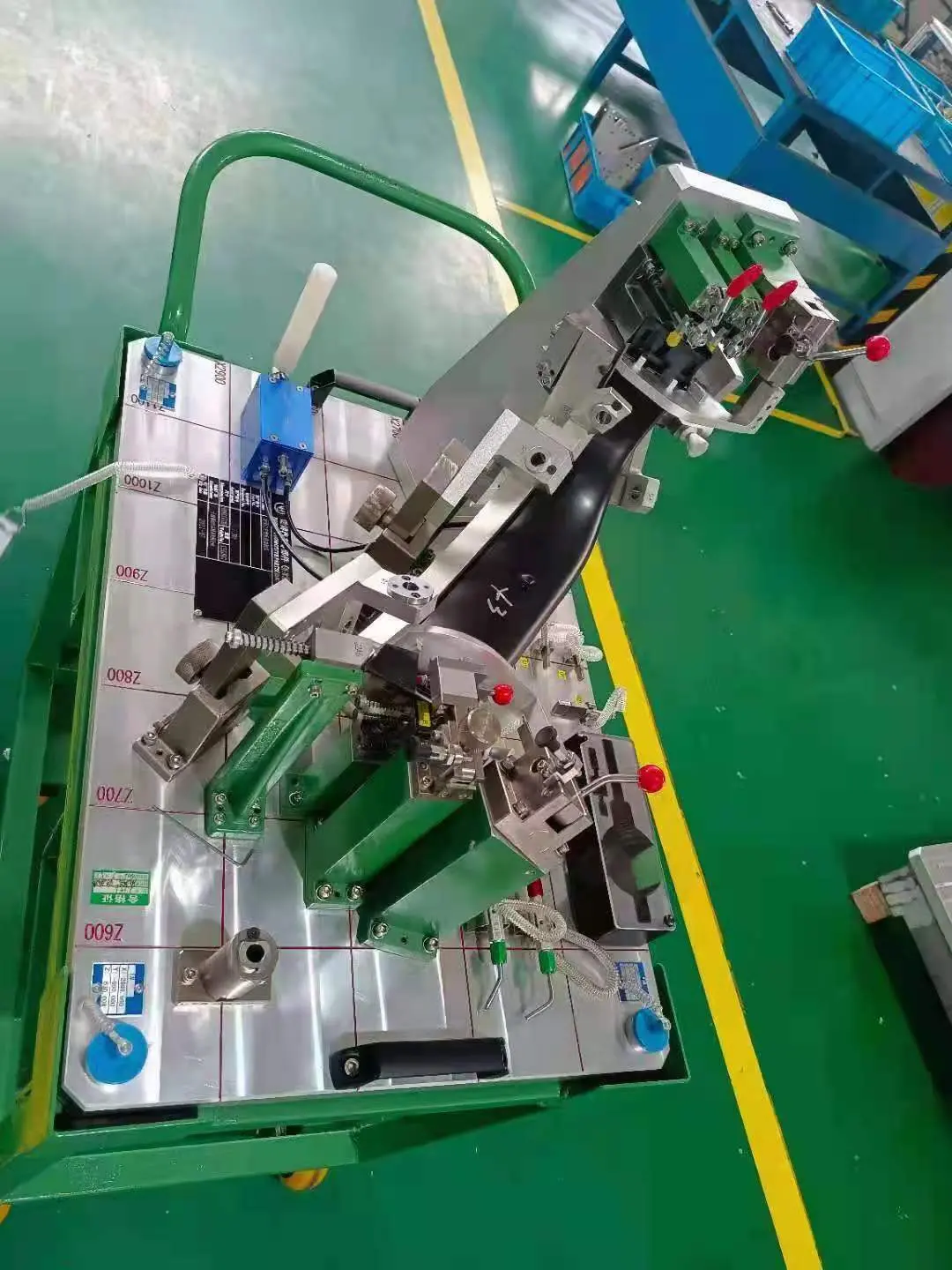

Automobile inspection tools are precision devices composed of basic functional components. Its purpose is to carefully check and verify whether the size, shape, position and other parameters of the part meet the design requirements. This ensures that each component meets the strict standards set by the manufacturer. Inspection tools include a range of measuring instruments, measuring tools, inspection jigs, etc., all of which are critical to maintaining the quality and accuracy of automotive parts.

One of the key reasons for the growing popularity of custom automotive inspection tools is the growing demand for high-quality automotive parts. As consumer expectations continue to rise, manufacturers are under pressure to deliver perfect products. This places a greater emphasis on precision engineering and quality control throughout the production process. By utilizing advanced inspection tools, manufacturers can ensure that each part meets accurate specifications, thereby improving the overall quality of the final product.

Additionally, the automotive industry is witnessing rapid technological advancements leading to more complex and complex designs. Therefore, traditional inspection methods are no longer sufficient to guarantee the precision and accuracy required for modern automobile manufacturing. Custom inspection tools are tailored to each manufacturer’s specific needs, allowing them to address the unique challenges presented by complex designs and complex components. This level of customization ensures that the inspection process meets the manufacturer’s specific requirements, increasing efficiency and accuracy.

Additionally, using custom car inspection tools can help save costs and increase efficiency. By integrating these tools into the manufacturing process, manufacturers can identify and correct any defects or discrepancies at an early stage, preventing costly rework and production delays. This proactive approach not only reduces the likelihood of defective parts reaching the market, but also streamlines the entire production process, thereby increasing efficiency and cost-effectiveness.

In addition to quality and efficiency benefits, adopting custom inspection tools can improve an automaker's overall reputation. By demonstrating a commitment to precision and quality, manufacturers can build trust and credibility with customers and stakeholders. In turn, this can increase customer satisfaction and loyalty, ultimately contributing to the long-term success and sustainability of the business.

In conclusion, the industry popularity of custom automotive inspection tools is a testament to the ever-changing needs of the automotive industry. As manufacturers strive to meet the demand for high-quality, precision-engineered components, the role of custom inspection tools is becoming increasingly important. By leveraging these advanced tools, manufacturers can maintain the highest standards of quality, efficiency, and customer satisfaction, ultimately positioning themselves as leaders in the highly competitive automotive market.