Revolutionizing automotive quality control with advanced inspection tools

The automotive industry continues to evolve, with manufacturers striving to meet stringent quality requirements while maintaining efficiency. One of the key challenges in this pursuit is the precise inspection of car seat frame assembly holes and surfaces. This is where advanced automotive inspection tools come into play, providing precise inspection capabilities to ensure that assembled parts meet the dimensional and positional tolerances specified in the design drawings.

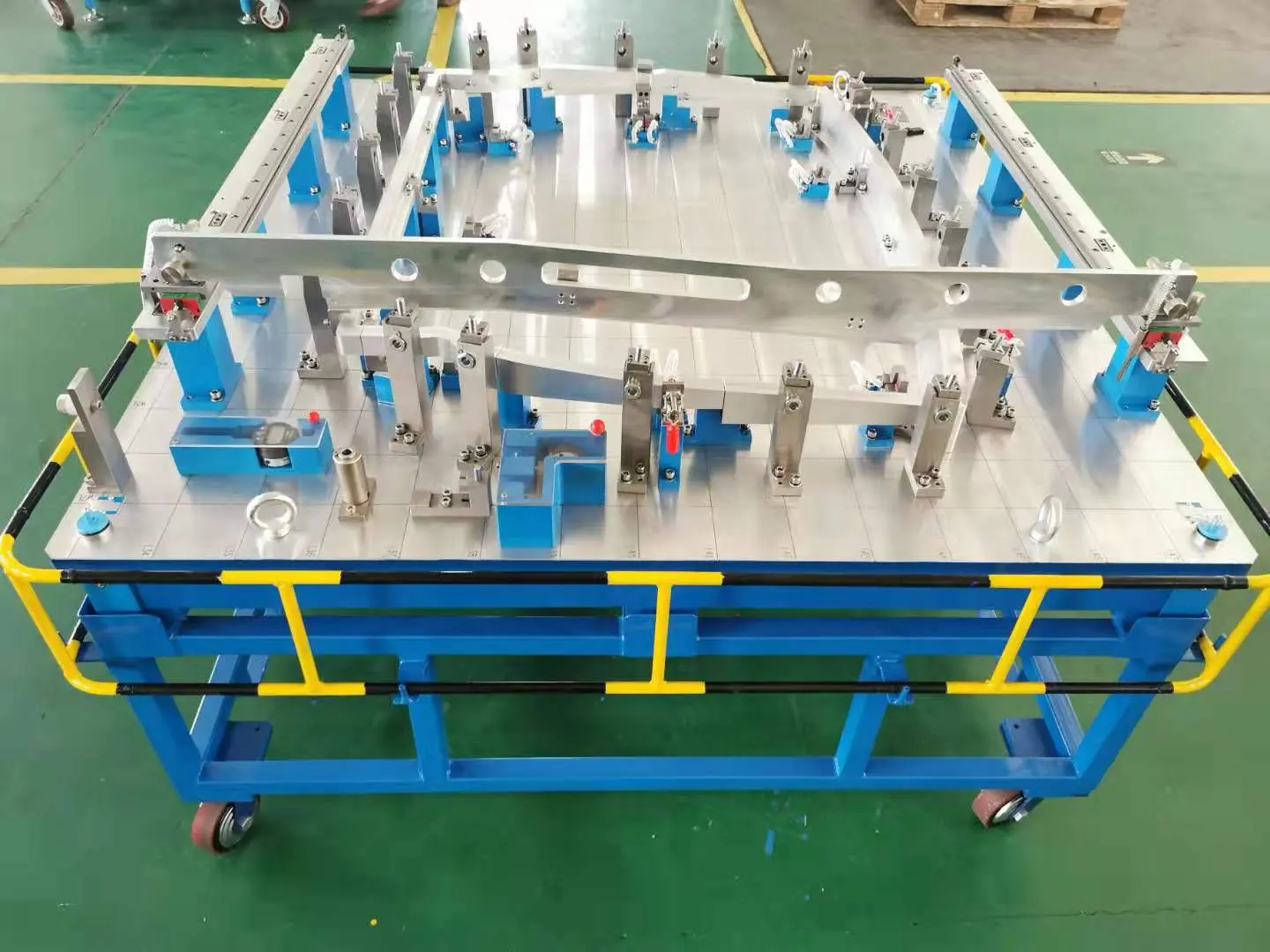

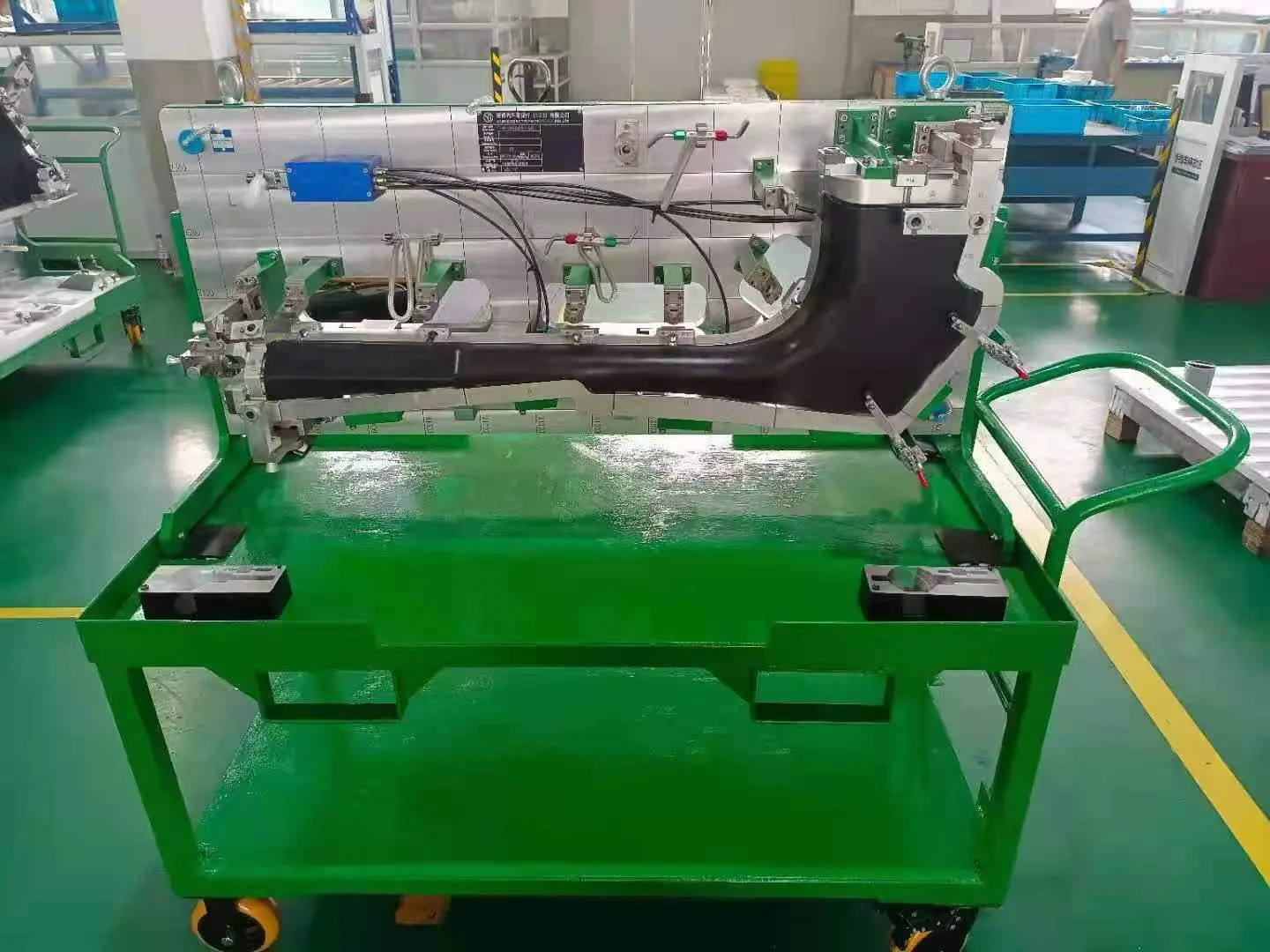

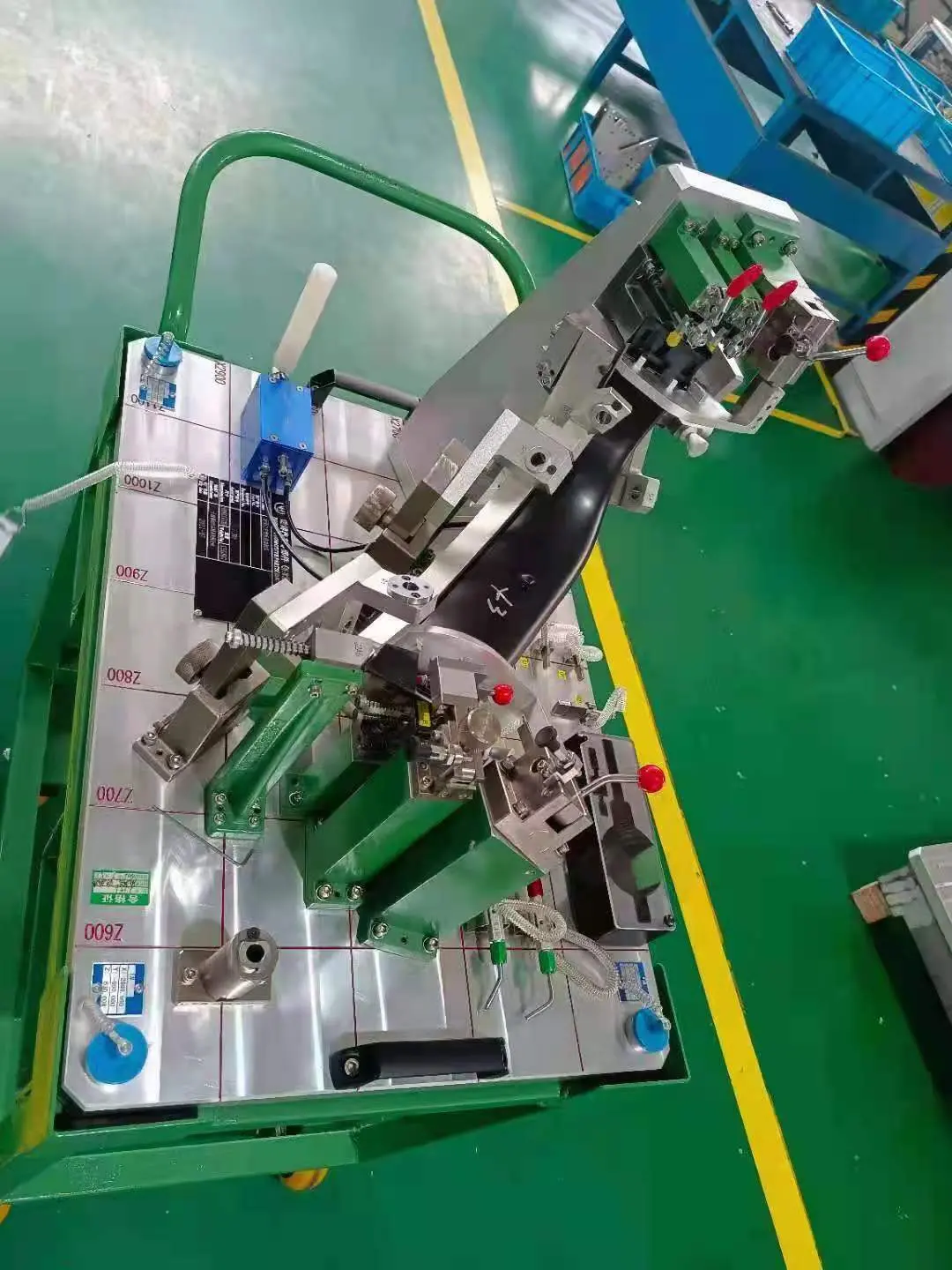

At the forefront of this technological advancement are state-of-the-art inspection tools that employ sophisticated inspection principles. By utilizing locating surfaces and pins, the tool securely holds the test part in place, allowing for seamless inspection. Position detection pins are then used to evaluate the alignment of the assembly holes, providing a reliable indication of whether the assembly meets the required standards. In addition, the tool features a go-stop gauge that allows the contoured surface to be scrutinized to ensure it meets design specifications.

The importance of these advanced inspection tools cannot be overstated as they play a key role in streamlining the quality control process in automotive manufacturing plants. These tools help increase efficiency and productivity by quickly identifying qualified parts and moving them to the next production stage in a timely manner. Instead, any nonconforming parts are immediately flagged for further evaluation, either by reshaping or, if necessary, scrapped. This proactive approach to quality control helps minimize rework and waste, ultimately saving costs and improving overall product quality.

As the automotive industry continues to embrace technological innovation, demand for cutting-edge inspection tools is set to soar. Manufacturers are increasingly recognizing the value of investing in advanced equipment that not only ensures compliance with quality standards but also improves operational efficiency. As automotive inspection technology advances rapidly, there is great promise for further improvements in quality control processes in the future, ultimately driving the industry to unprecedented levels of accuracy and reliability.

In summary, the integration of advanced automotive inspection tools represents a critical advancement in the automotive manufacturing industry’s pursuit of uncompromising quality. By leveraging the latest technologies and inspection principles, these tools promise to revolutionize the way quality is controlled, setting new benchmarks for accuracy and efficiency. As the industry continues to evolve, the role of advanced inspection tools will undoubtedly become increasingly indispensable, shaping the future of automotive manufacturing and reinforcing the commitment to delivery excellence.