Leveraging Industry Knowledge of Automotive Inspection Tools to Improve Manufacturing Accuracy

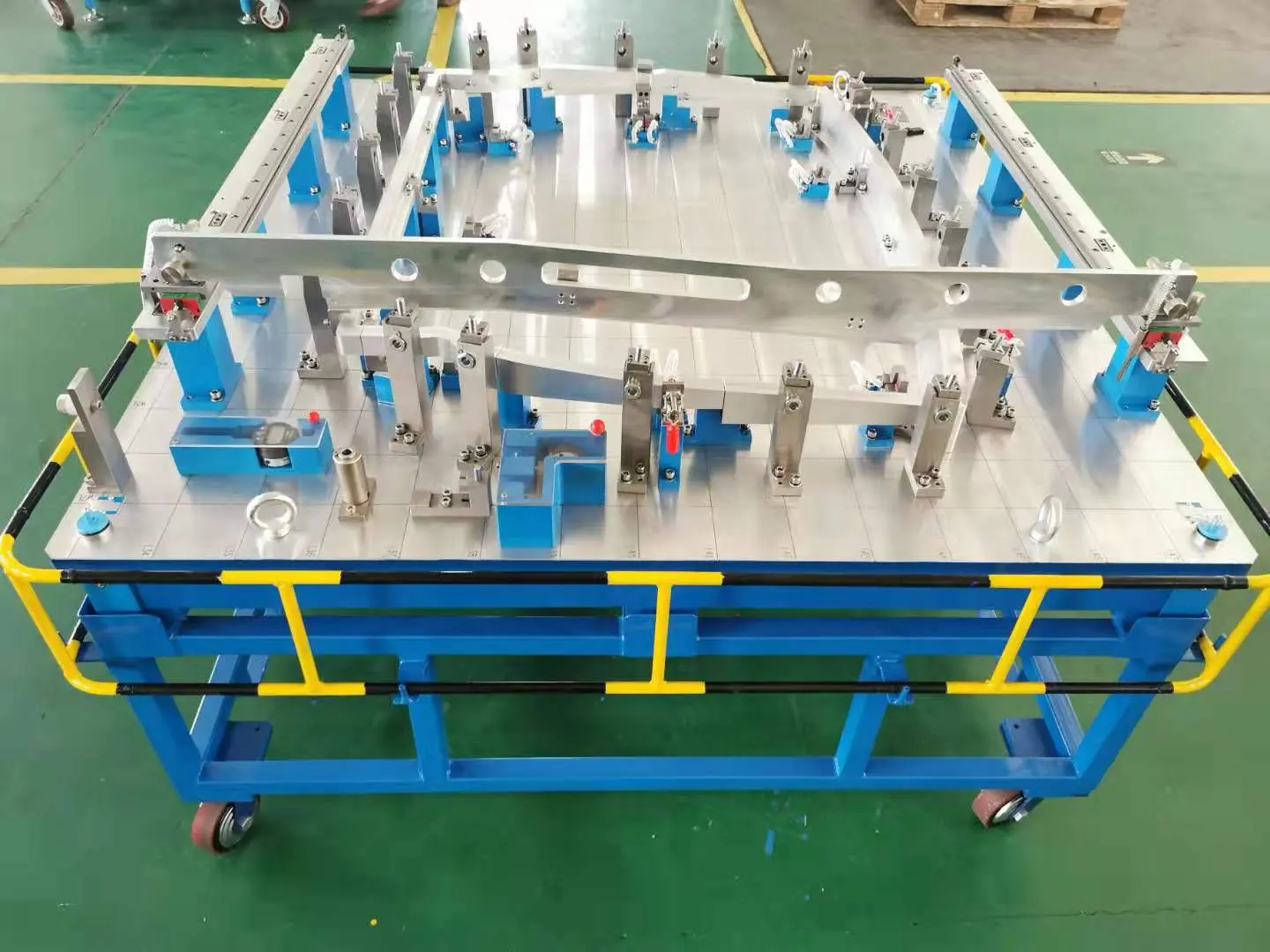

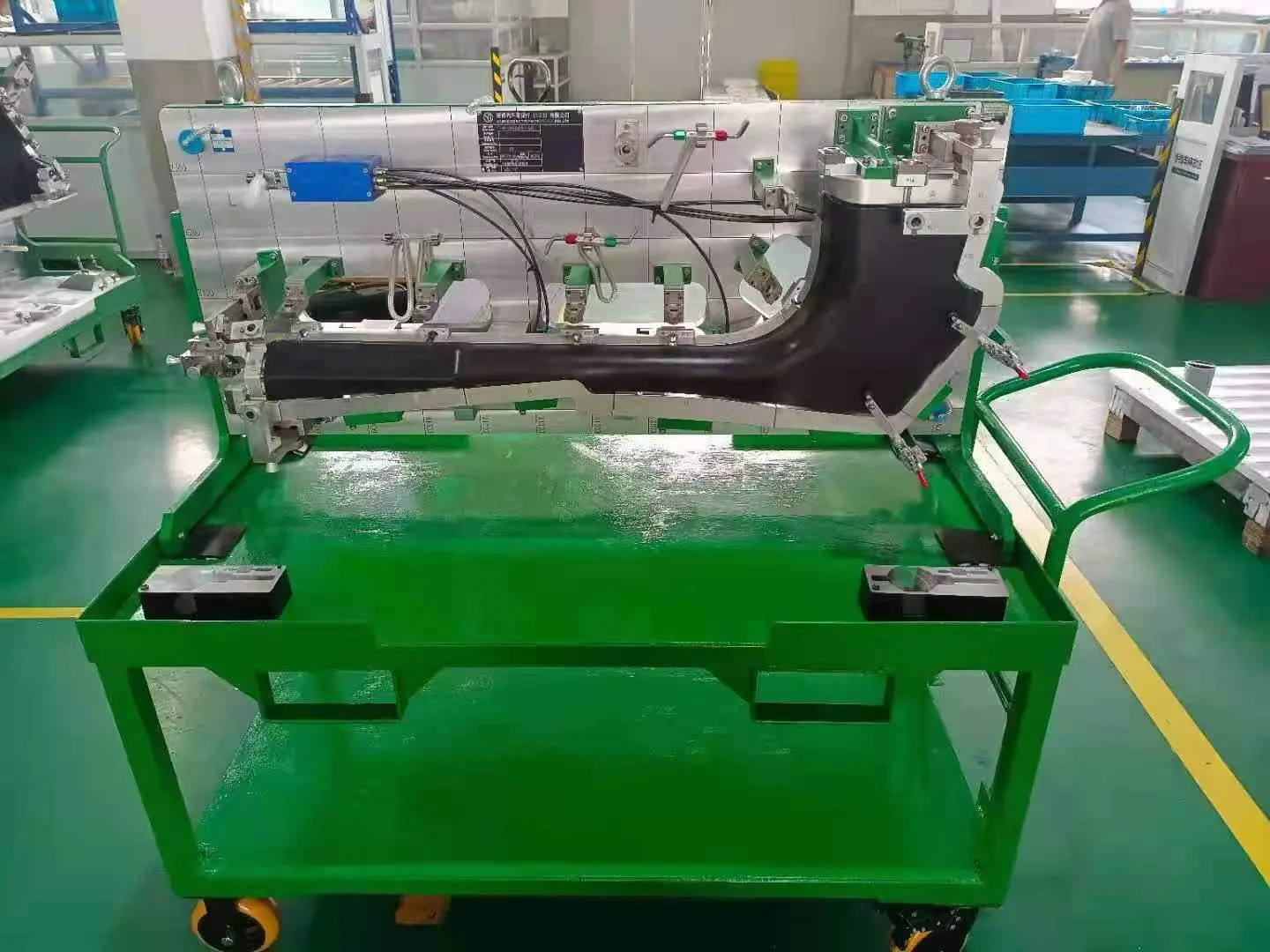

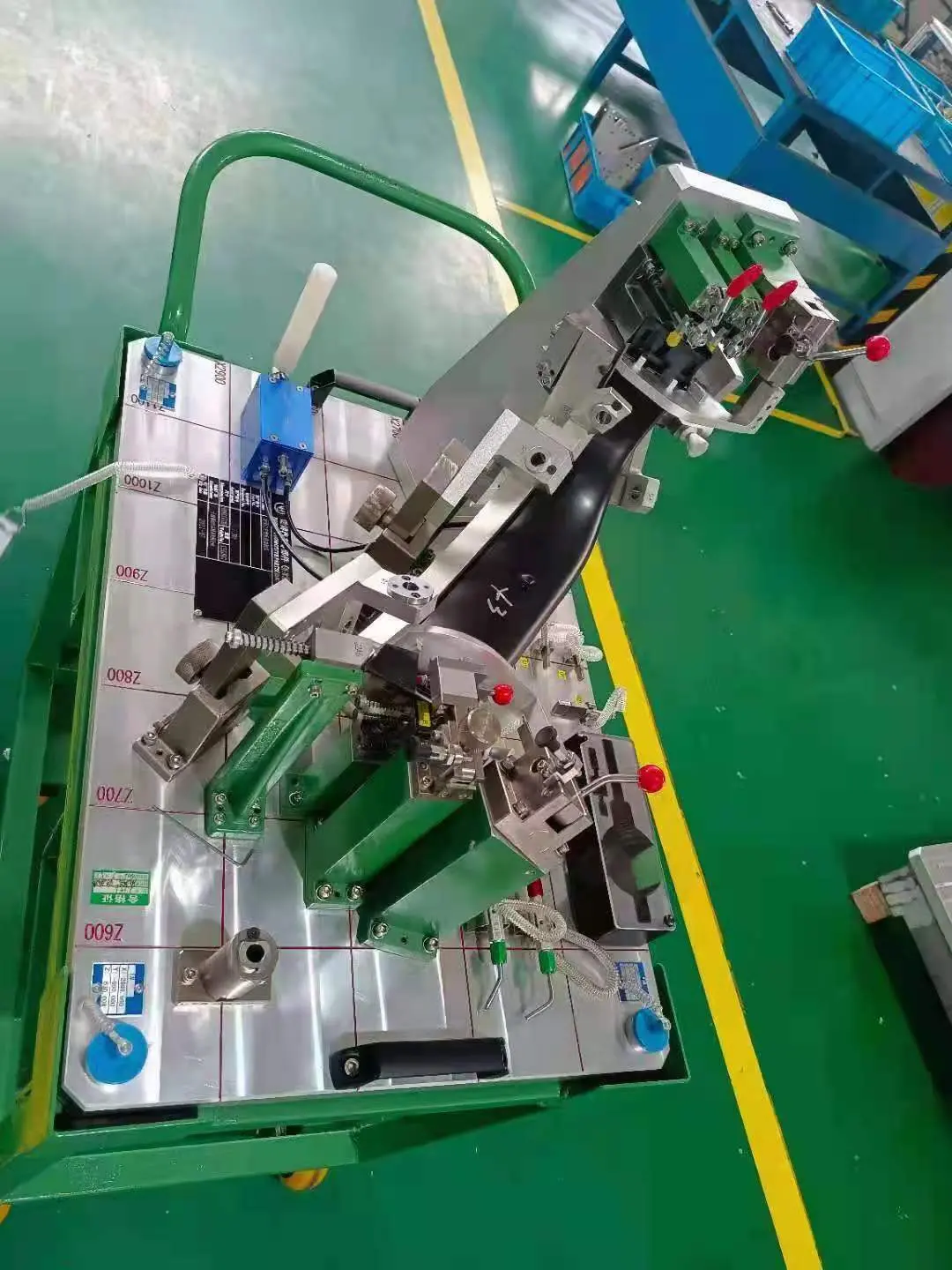

Automobile inspection tools are customized according to special requirements and consist of basic functional components. These tools are critical equipment used to inspect and verify parts during the manufacturing process. By cooperating with reputable inspection tool manufacturers, automobile manufacturers can ensure that each part meets the design requirements, using measuring instruments, measuring tools, inspection tools, etc. to check and verify whether the size, shape, position and other parameters of the part meet the design requirements. Parts meet design specifications.

One of the main benefits of using automotive inspection tools is the ability to customize them to specific manufacturing needs. This customization ensures that the tools are tailored to the unique requirements of the automotive production process, allowing for precise and accurate inspection of components. Whether ensuring the precise dimensions of engine components or verifying the alignment of body panels, these tools play a critical role in maintaining the highest quality standards in automotive manufacturing.

Additionally, the use of automotive inspection tools not only improves the accuracy of the manufacturing process but also helps improve overall efficiency. By inspecting and validating parts during production, manufacturers can detect and resolve any issues or discrepancies early, preventing costly rework or potential defects in the final product. This proactive approach to quality control ultimately saves time and resources, resulting in a more streamlined and cost-effective manufacturing process.

In addition to ensuring quality and efficiency, automotive inspection tools help ensure the safety and reliability of the final automotive product. By carefully inspecting and validating every component, manufacturers can be confident that the finished vehicle meets the highest safety and performance standards. This is especially important in an industry where even the slightest deviation from specifications can have a significant impact on the end user.

The importance of automotive inspection tool industry knowledge cannot be overstated. Manufacturers must stay up to date on the latest advances and best practices in inspection technology to remain competitive in the ever-evolving automotive industry. From advances in precision measurement technology to the integration of digital inspection systems, understanding the latest trends and innovations in automotive inspection tools is critical to maintaining a competitive advantage.

To sum up, automobile inspection tools are indispensable in the manufacturing process and play a decisive role in ensuring the accuracy, efficiency and quality of automobile production. By leveraging industry knowledge and partnering with reputable inspection tool manufacturers, automakers can adhere to the highest quality control standards, ultimately providing consumers with safe, reliable and high-performance vehicles. As the automotive industry continues to evolve, it is critical for manufacturers who want to maintain a competitive edge in the market to stay abreast of the latest advances in automotive inspection tools.