Importance of Inspection Fixtures in Sheet Metal Manufacturing

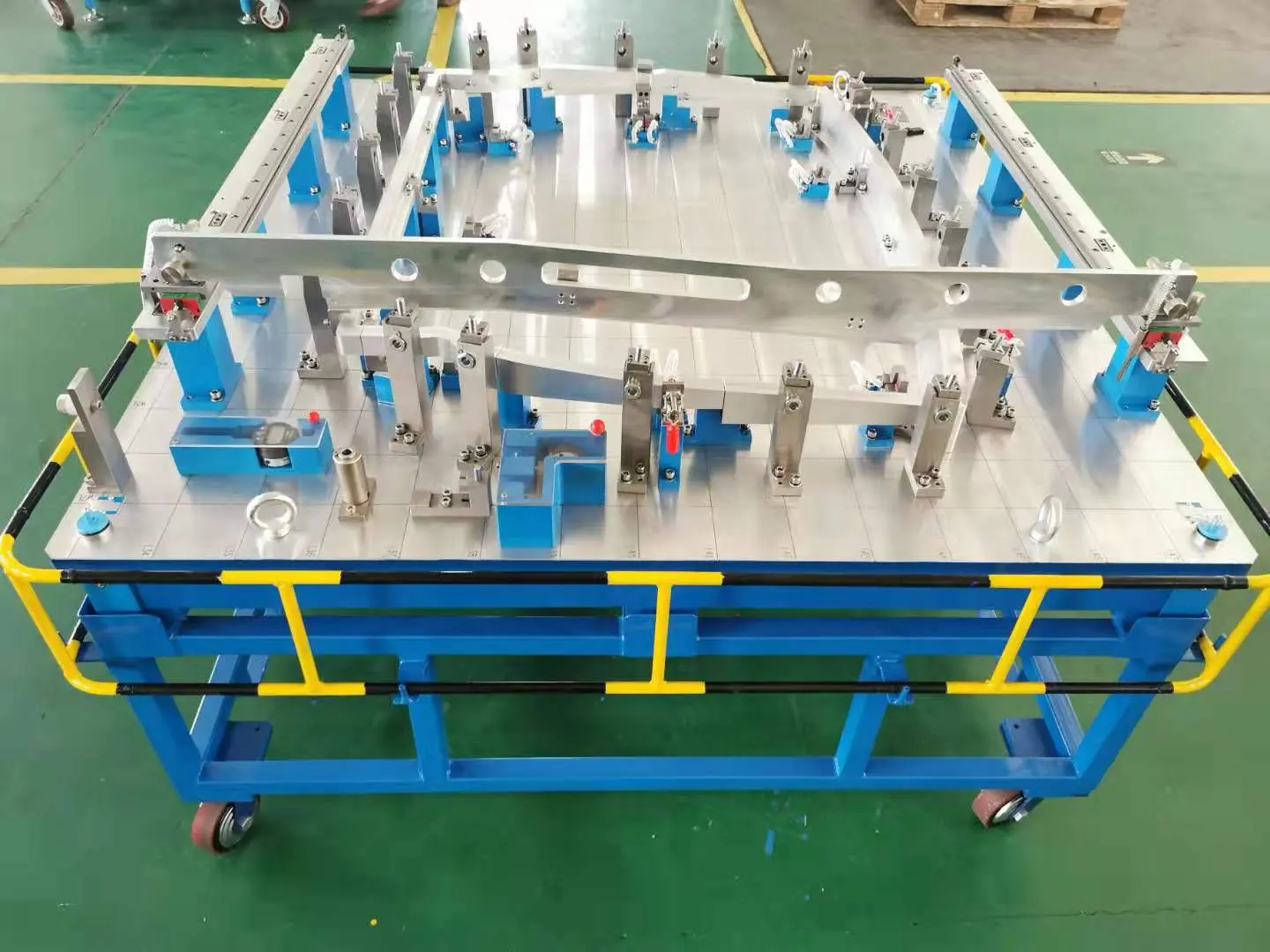

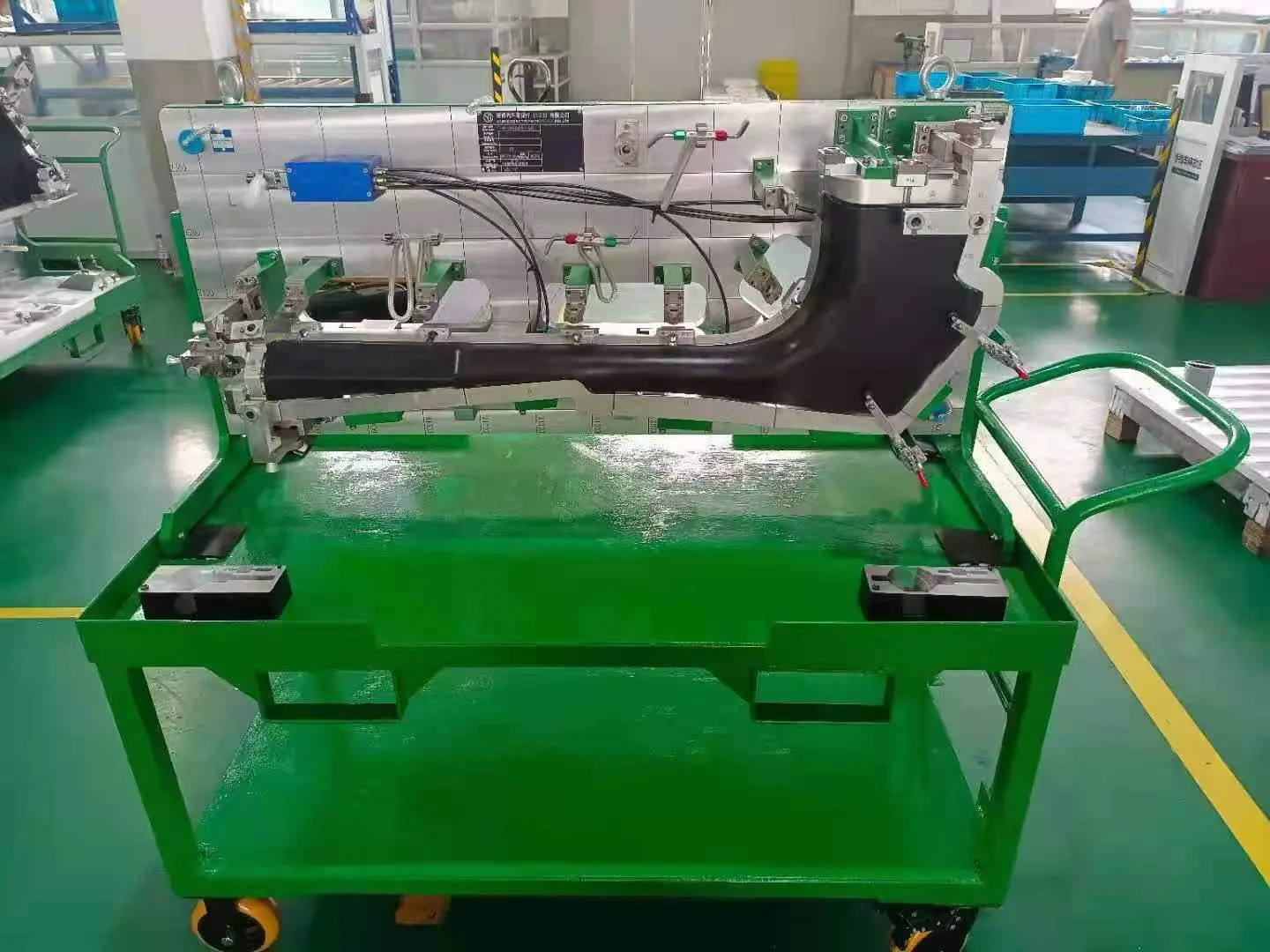

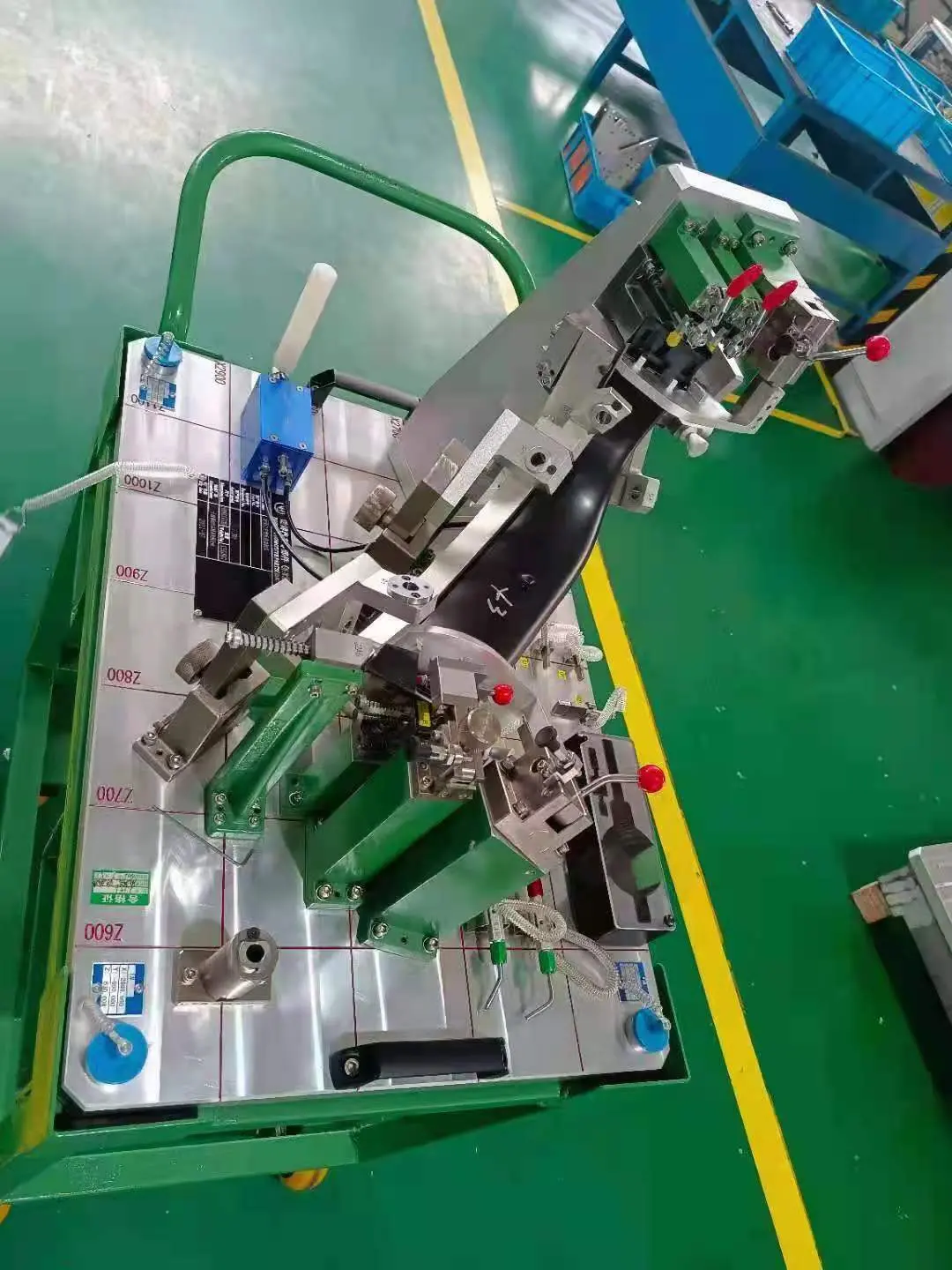

Checking fixtures are specially designed tools used to verify the dimensional accuracy and alignment of sheet metal components during the fabrication process. These fixtures are custom-made to match the specific geometry and tolerances of the parts being produced, allowing manufacturers to ensure that each component meets the required specifications. By using checking fixtures, manufacturers can identify and rectify any deviations or defects in the parts early in the production process, ultimately saving time and resources.

In sheet metal fabrication, precision is paramount, and checking fixtures play a crucial role in maintaining the desired level of accuracy. By using these fixtures, manufacturers can verify the dimensional integrity of sheet metal components, ensuring that they meet the exact specifications outlined in the design. This level of precision is essential for ensuring the proper fit and function of the final product, whether it's a complex automotive component or a simple household appliance.

Furthermore, checking fixtures are instrumental in streamlining the production process and minimizing the risk of errors or rework. By using these fixtures to validate the quality of sheet metal components at various stages of production, manufacturers can identify and address any issues early on, preventing costly delays and rework down the line. This proactive approach not only saves time and resources but also contributes to the overall efficiency and reliability of the fabrication process.

In addition to ensuring dimensional accuracy, checking fixtures also play a crucial role in maintaining consistency across multiple parts or batches. By using these fixtures to verify the uniformity of sheet metal components, manufacturers can guarantee that each part meets the same high standards of quality and precision. This level of consistency is essential for meeting the demands of modern manufacturing, where uniformity and reliability are key factors in delivering high-quality products to customers.

In conclusion, checking fixtures are indispensable tools in the sheet metal fabrication process, playing a critical role in verifying the dimensional accuracy, alignment, and consistency of components. By using these fixtures, manufacturers can ensure that each part meets the required specifications, ultimately contributing to the overall quality and reliability of the end product. As the manufacturing industry continues to evolve, the importance of checking fixtures in sheet metal fabrication cannot be overstated, and their role in maintaining precision and consistency will remain essential for years to come.