Growing popularity of automotive inspection tools in manufacturing

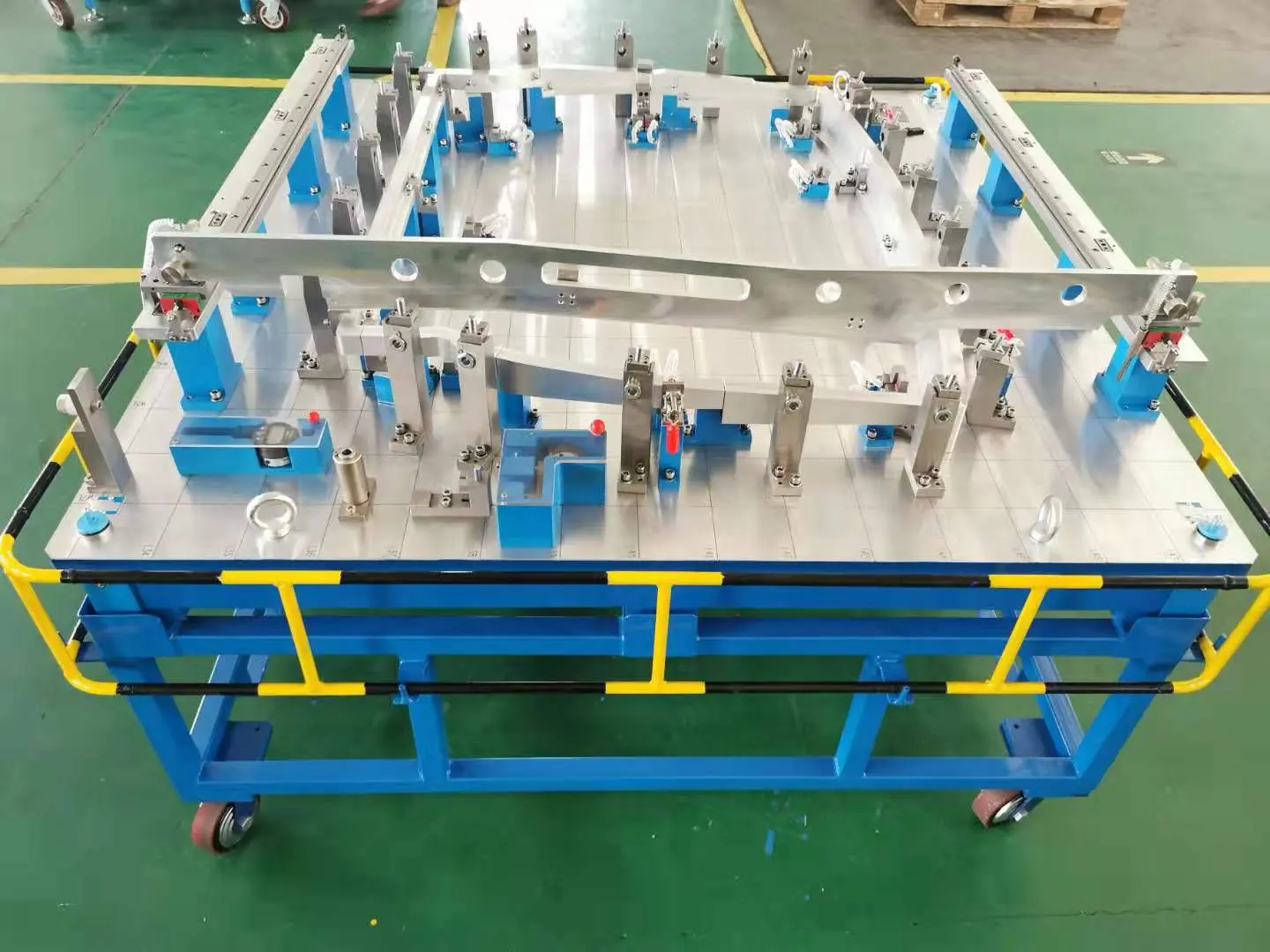

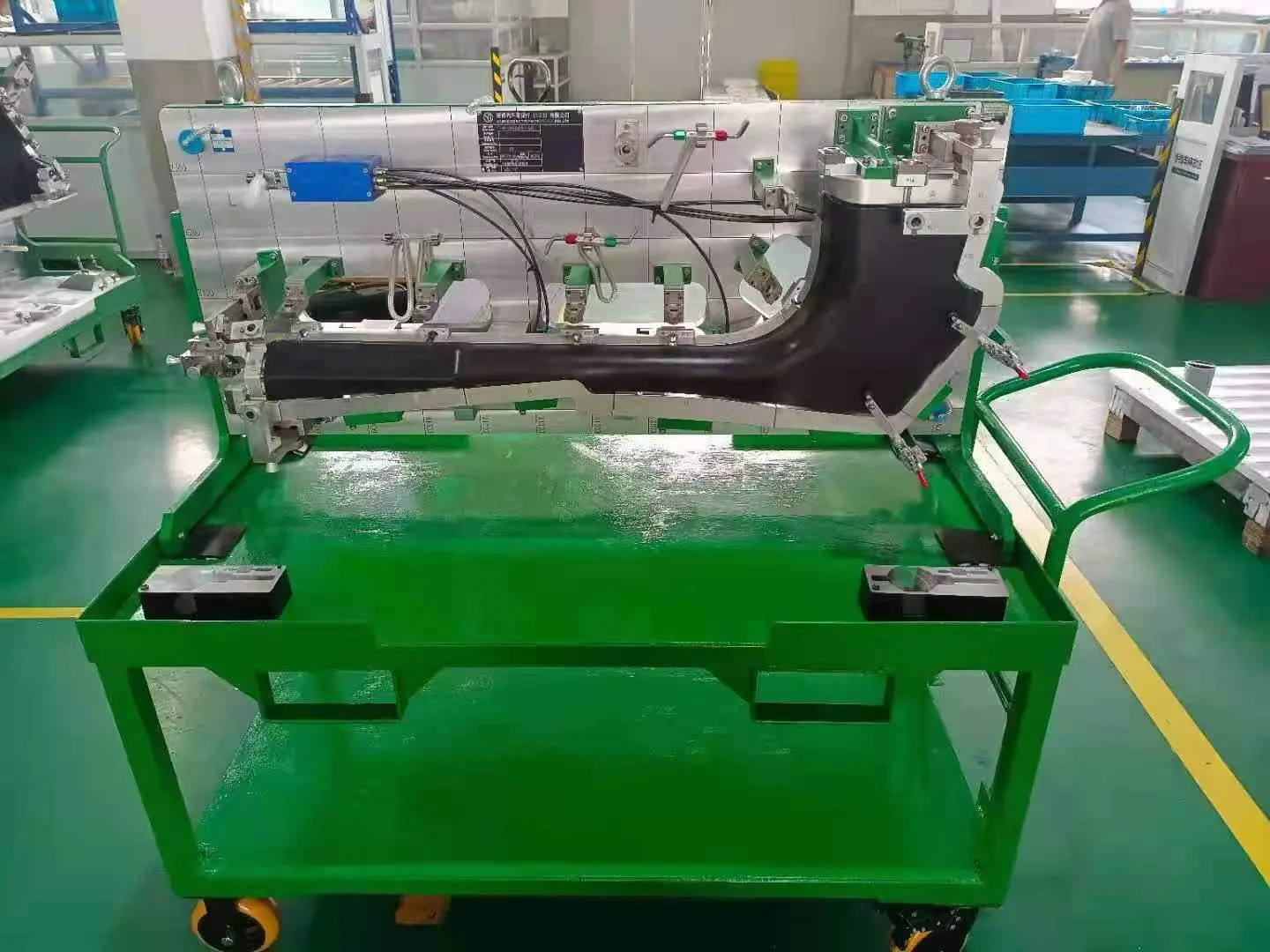

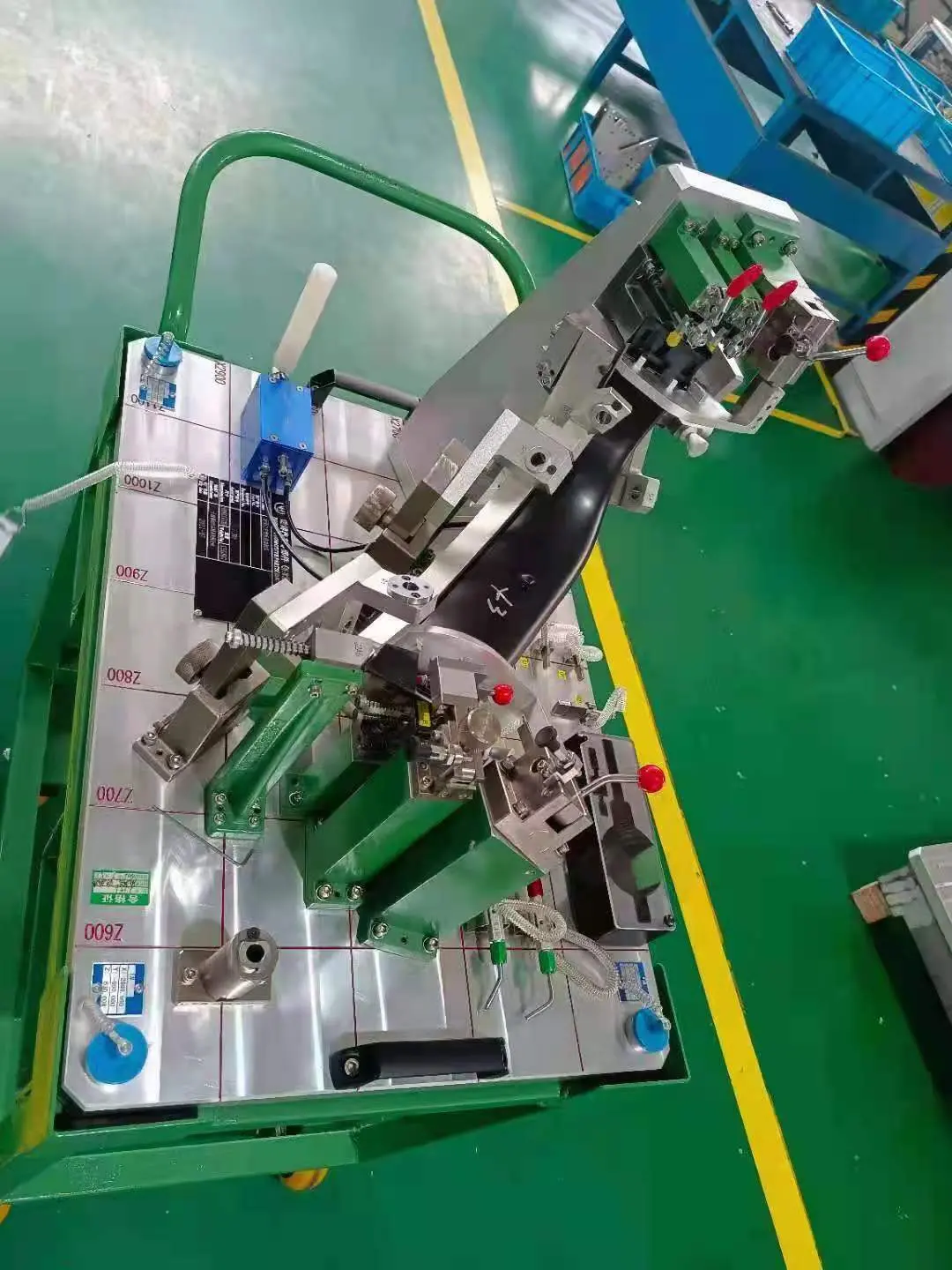

Automotive testers are complex devices that play a vital role in maintaining high standards of quality control in the automotive industry. It consists of functional components of the matrix, including measuring instruments, measuring tools, inspection tools, etc. These components work together to check and verify whether the size, shape, position and other parameters of the part meet the design requirements.

One of the key reasons for the growing popularity of automotive inspection tools is the strict quality standards and regulations that manufacturers need to adhere to. With the increasing complexity of modern vehicles and the need for precision engineering, the margin for error in the manufacturing process is smaller than ever. As a result, manufacturers are turning to advanced inspection tools to ensure every part meets design requirements, minimizing the risk of defects and ensuring customer satisfaction.

Additionally, using automotive inspection tools has proven to be a cost-effective investment for manufacturers. By detecting and correcting any deviations from design specifications early in the production process, these tools help prevent costly rework and scrap, ultimately saving time and resources. This proactive approach to quality control not only improves the overall efficiency of the manufacturing process, it also helps reduce waste and rework, resulting in significant cost savings in the long run.

In addition to their role in quality control, automotive inspection tools also help optimize production processes. By providing accurate and reliable data on the dimensions and characteristics of manufactured parts, these tools enable manufacturers to identify and resolve any potential issues in real time, streamlining production workflows and minimizing downtime. This proactive approach to quality assurance not only improves the overall efficiency of the manufacturing process, it also helps reduce waste and rework, resulting in significant cost savings in the long run.

The growing popularity of automotive inspection tools is also driven by technological advancements. By integrating cutting-edge capabilities such as automated measurement, data analysis and real-time monitoring, these tools have become indispensable for manufacturers to stay ahead in a highly competitive market. The ability to capture and analyze large amounts of data accurately and quickly has revolutionized the way manufacturers conduct quality control, allowing them to make informed decisions and drive continuous improvement in their production processes.

In summary, the growing popularity of automotive inspection tools in the manufacturing industry is a testament to the indispensable role they play in ensuring the quality, accuracy, and reliability of automotive parts. As manufacturers continue to prioritize quality control and efficiency, the demand for advanced inspection tools customized to specific requirements is expected to grow further. By leveraging the capabilities of these advanced tools, manufacturers can adhere to the highest quality standards, optimize their production processes, and ultimately gain a competitive advantage in the dynamic automotive market.