Enhancing Product Knowledge: The Importance of Automotive Inspection Tools

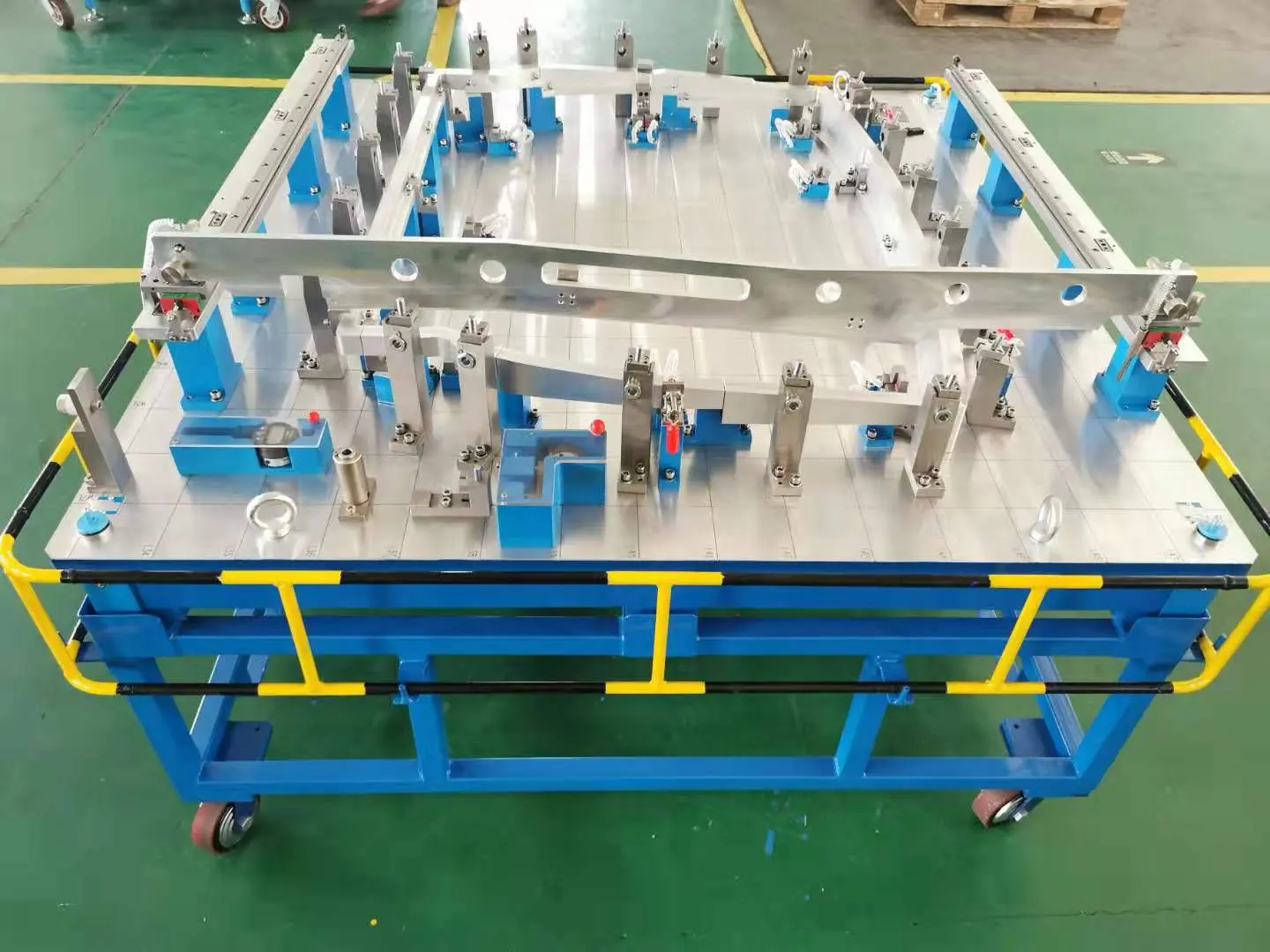

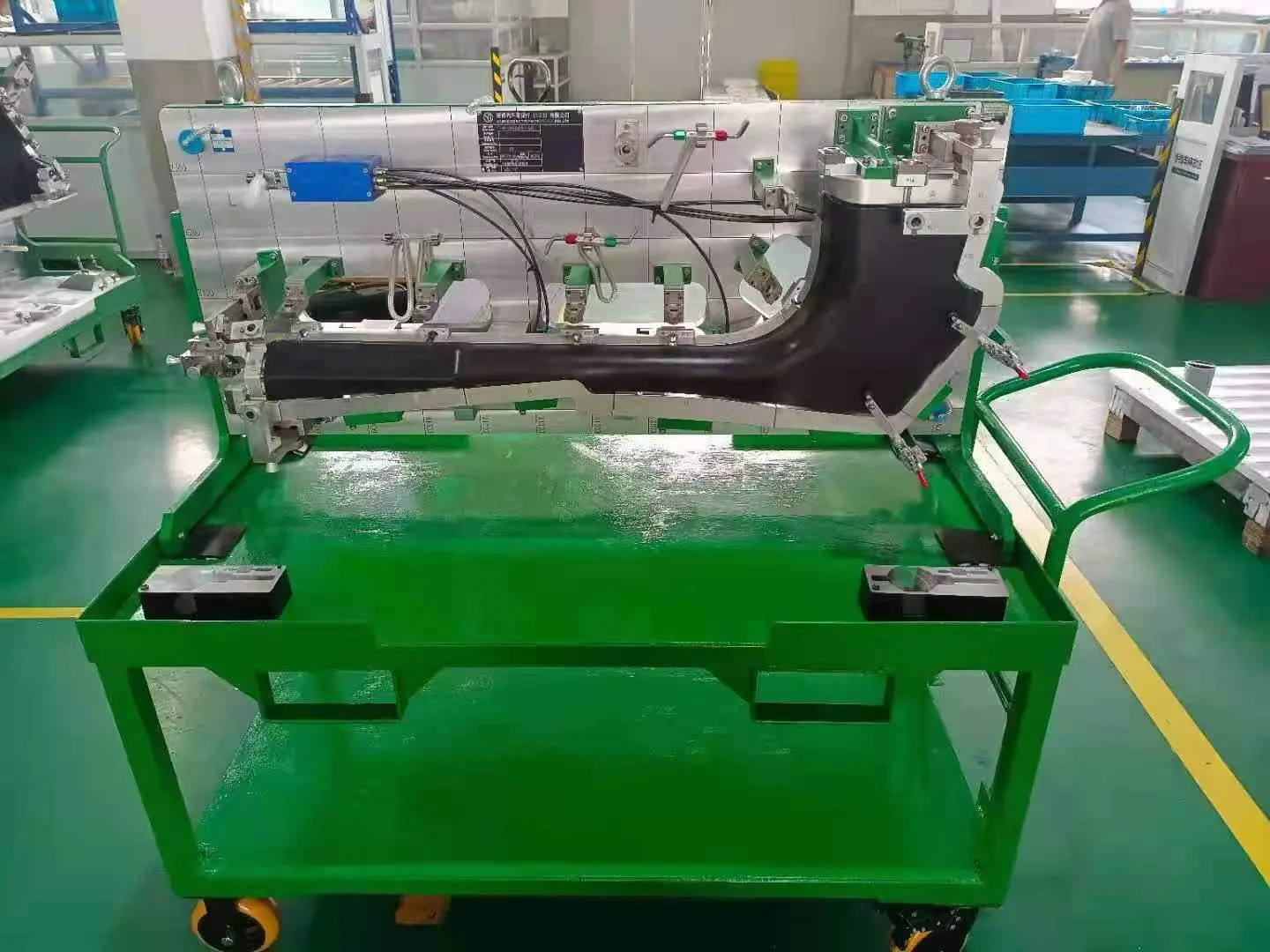

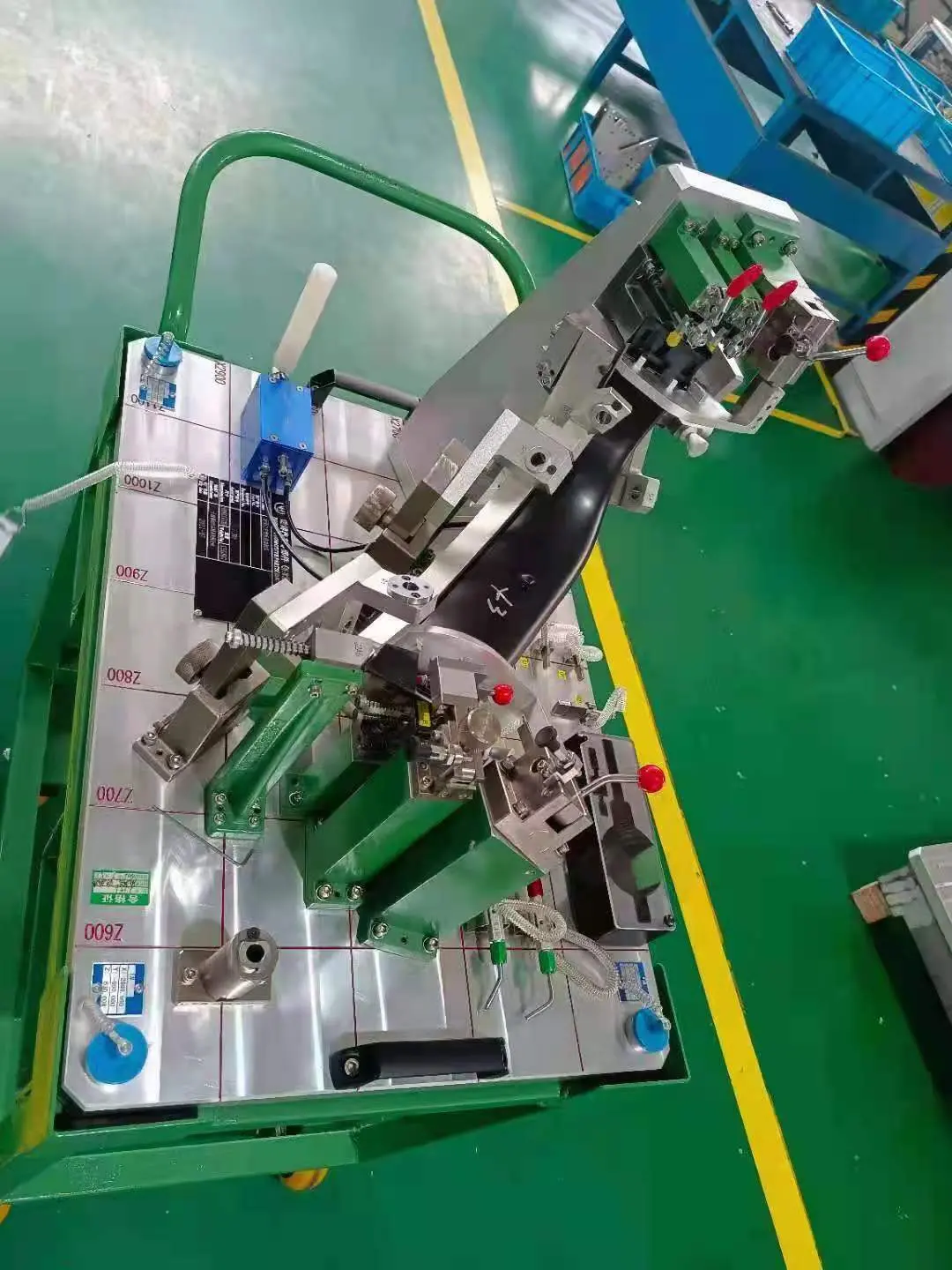

First, it is critical for manufacturers and quality control professionals to understand the intricacies of automotive inspection tools. These tools are designed to carefully measure and evaluate various aspects of automotive parts, such as dimensions, tolerances and surface finish. With comprehensive product knowledge, individuals can effectively utilize these tools to identify any deviations from specified standards, ensuring only high-quality parts make it to the final assembly. By becoming familiar with the capabilities and limitations of automotive inspection tools, manufacturers can streamline their production processes and minimize the risk of finished vehicle defects or failures.

Additionally, having in-depth automotive inspection tool product knowledge enables professionals to make informed decisions regarding the selection and implementation of these instruments. There are different types of inspection tools on the market, each tailored to specific measurement requirements. By understanding the unique features and capabilities of these tools, manufacturers can make strategic choices that fit their production needs. Whether it's a precision caliper for dimensional measurements or a surface roughness tester for evaluating the quality of machined surfaces, a comprehensive understanding of these tools enables professionals to optimize their inspection processes and enhance overall quality control.

Additionally, product knowledge plays a key role in ensuring the accuracy and reliability of test results. Automotive inspection tools provide precise measurements that directly impact vehicle performance and safety. Therefore, a thorough understanding of these tools, including their calibration procedures and potential sources of error, is critical to maintaining the integrity of the inspection process. With the right product knowledge, professionals can effectively resolve any issues that may arise during the inspection process, maintaining the highest quality and compliance standards.

Additionally, leveraging product knowledge from automotive inspection tools can also contribute to continuous improvement initiatives in manufacturing environments. By staying abreast of the latest advances in inspection technology and methods, professionals can identify opportunities to enhance inspection processes and adapt to evolving industry standards. This proactive approach not only fosters a culture of innovation and excellence, but also enables manufacturers to meet the growing demand for precision and efficiency in automotive production.

In summary, the importance of product knowledge when it comes to automotive inspection tools cannot be overstated. By providing professionals with in-depth knowledge of these critical instruments, manufacturers can improve quality control practices, make informed decisions, ensure measurement accuracy and drive continuous improvement. As the automotive industry continues to evolve, adopting a comprehensive product knowledge approach will undoubtedly become a key differentiator to achieve excellence and competitiveness in the global market.