Enhance Industry Knowledge with Custom Automotive Inspection Tools

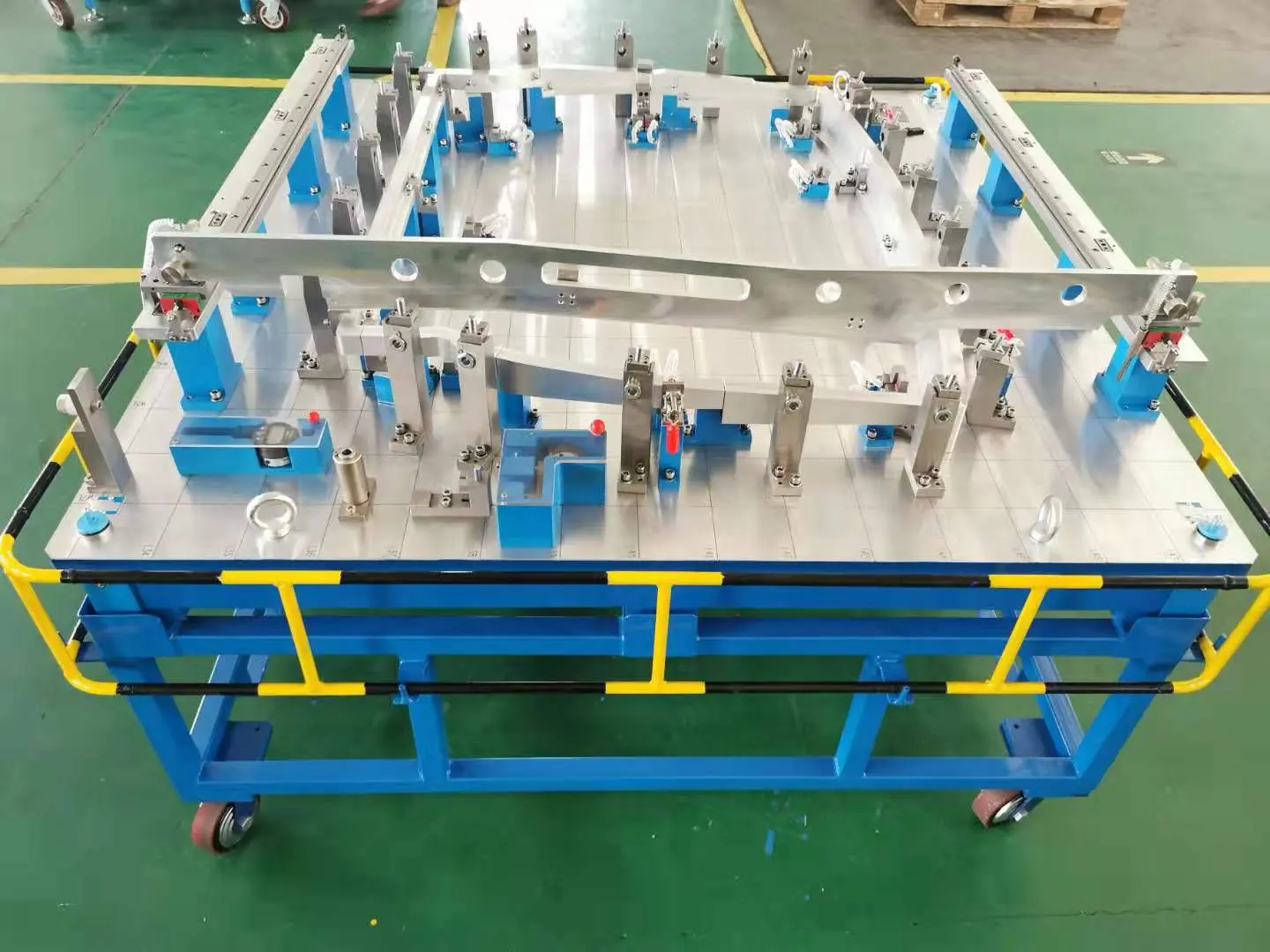

Automotive inspection tools play a vital role in maintaining the quality and integrity of automotive components. By partnering with a reputable inspection tool manufacturer, automotive companies can ensure that every part meets design requirements. These tools include a range of measuring instruments, measurement tools, and inspection jigs, all designed to check and verify that the size, shape, location, and other parameters of a part comply with design specifications.

The customization of automotive inspection tools is a key aspect that makes it stand out in the industry. Each tool is tailored to the manufacturer's specific needs, taking into account the unique requirements of the component being produced. This level of customization ensures that the inspection process is not only accurate but also efficient, ultimately helping to increase productivity and cost-effectiveness.

One of the main benefits of using custom automotive inspection tools is the ability to maintain consistency and accuracy throughout the manufacturing process. Due to the complexity of automotive components, even the slightest deviation from design specifications can have a significant impact on performance and safety. By utilizing specialized inspection tools, manufacturers can maintain the highest quality standards of their products by reducing the risk of defects and nonconformities.

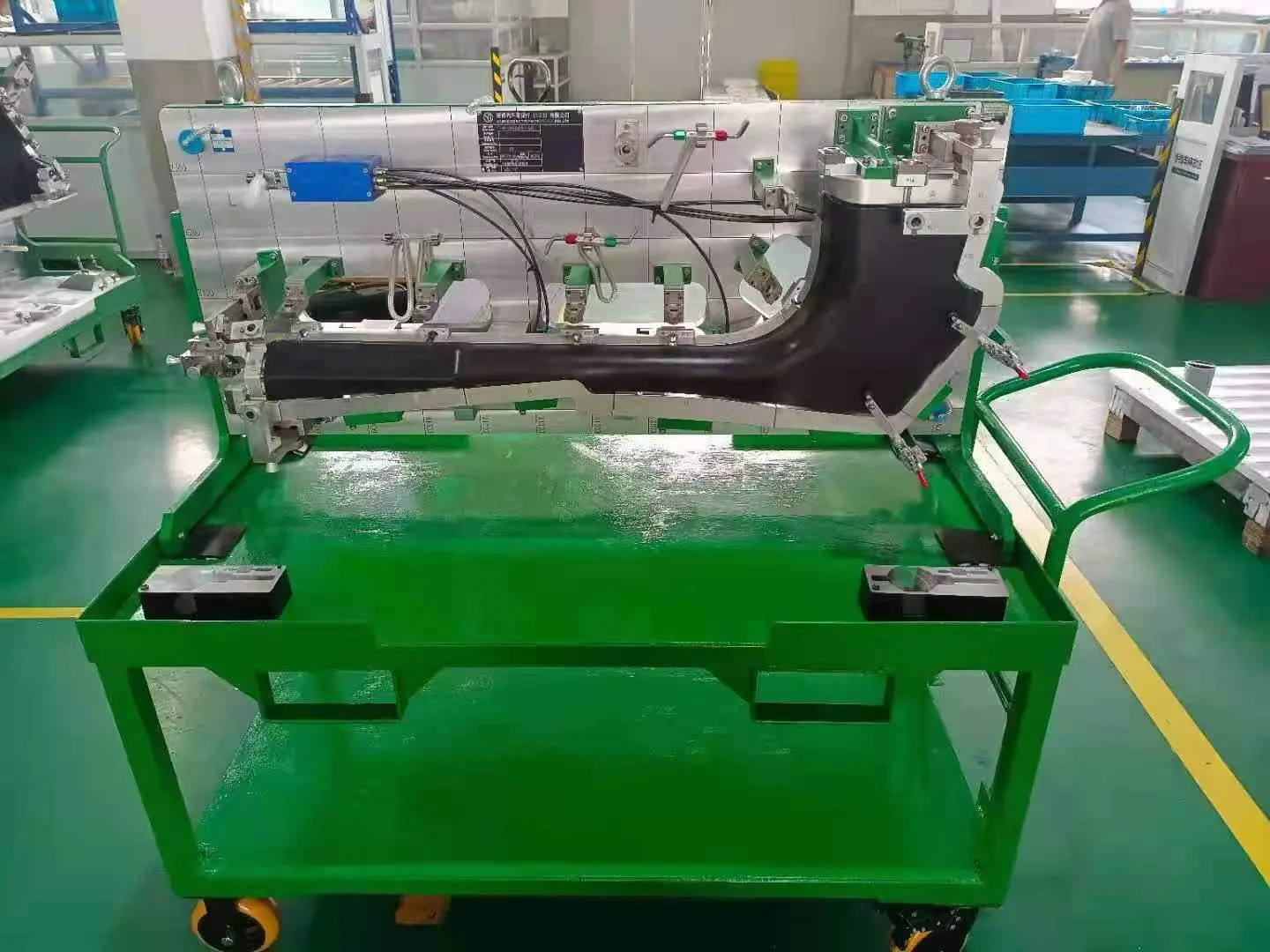

Additionally, the integration of advanced technologies in these inspection tools enhances their capabilities, allowing for more comprehensive and detailed analysis of components. This advanced capability enables manufacturers to detect potential problems early, helping to adjust and improve production processes in a timely manner. As a result, the overall quality of auto parts is improved to meet the stringent requirements of the industry and consumers.

In addition to ensuring compliance with design requirements, custom automotive inspection tools help optimize production processes. By streamlining inspection and verification procedures, manufacturers can achieve greater efficiency and throughput, ultimately reducing lead times and improving overall operational performance. This not only saves costs, but also allows car companies to gain greater competitiveness in the market.

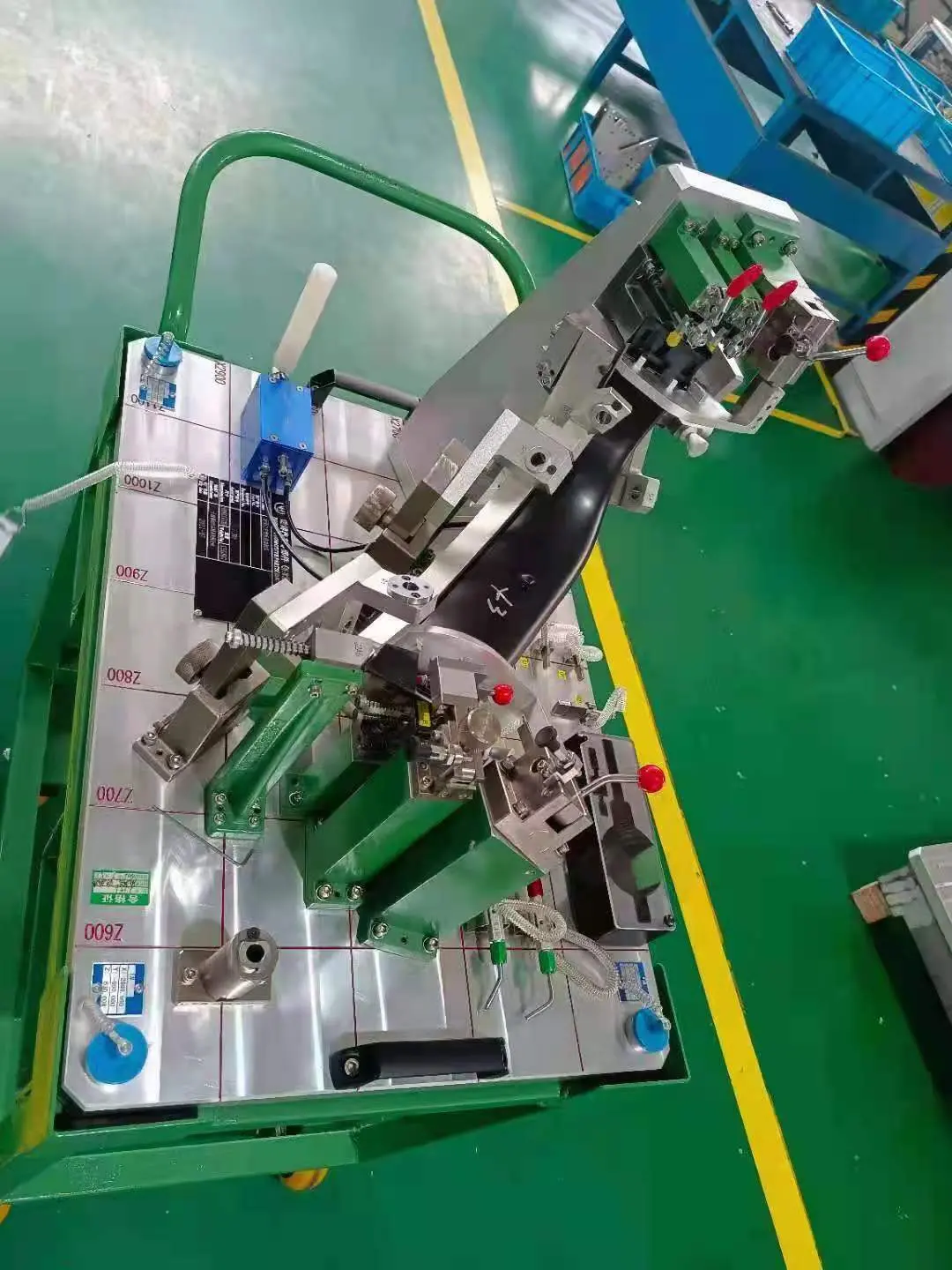

The importance of industry knowledge in the field of automotive inspection tools cannot be overstated. Manufacturers must stay abreast of the latest advances and best practices in inspection technology to stay at the forefront of quality and innovation. By leveraging the expertise of reputable inspection tool manufacturers, automotive companies can obtain cutting-edge solutions that comply with industry standards and regulatory requirements.

In summary, using custom automotive inspection tools helps maintain the highest quality and accuracy standards in the automotive industry. These tools are tailored to the manufacturer's specific needs and play a key role in ensuring that each component meets stringent design and performance requirements. By absorbing industry knowledge and leveraging advanced inspection technologies, automotive companies can enhance their production processes and deliver high-quality products to meet the needs of today's discerning market.