01

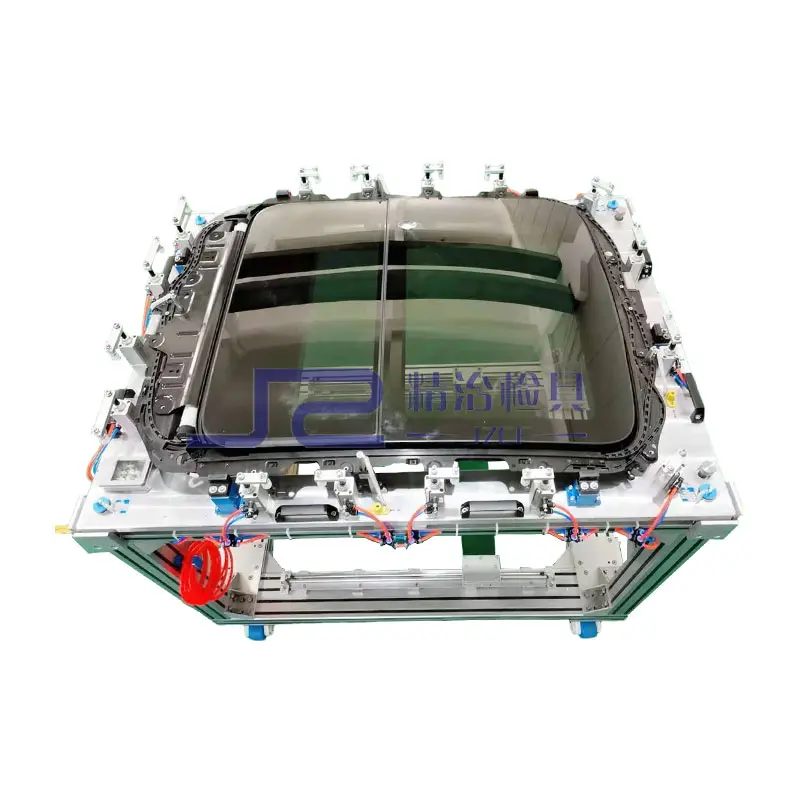

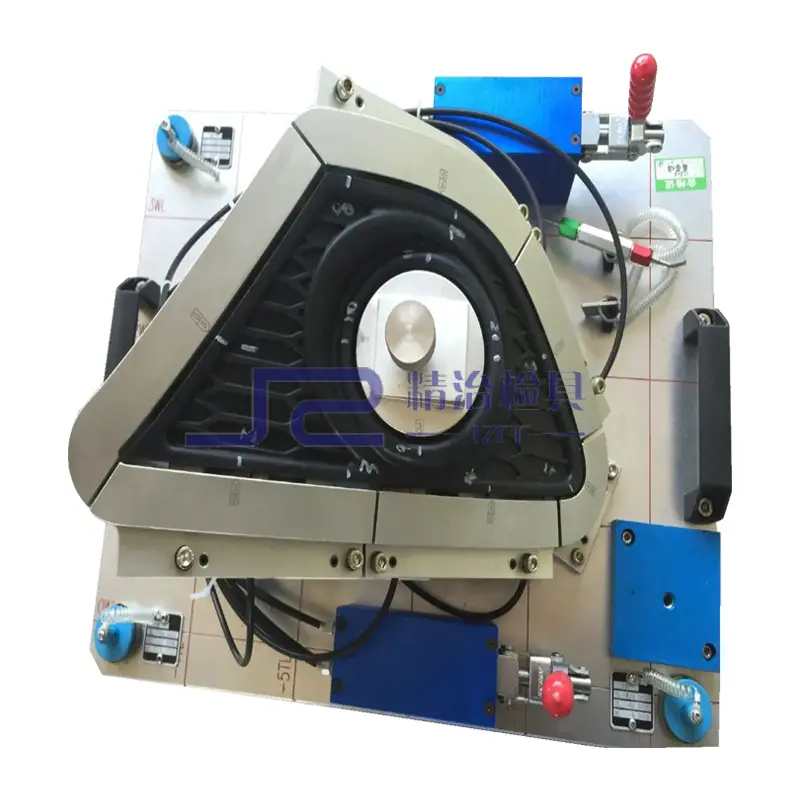

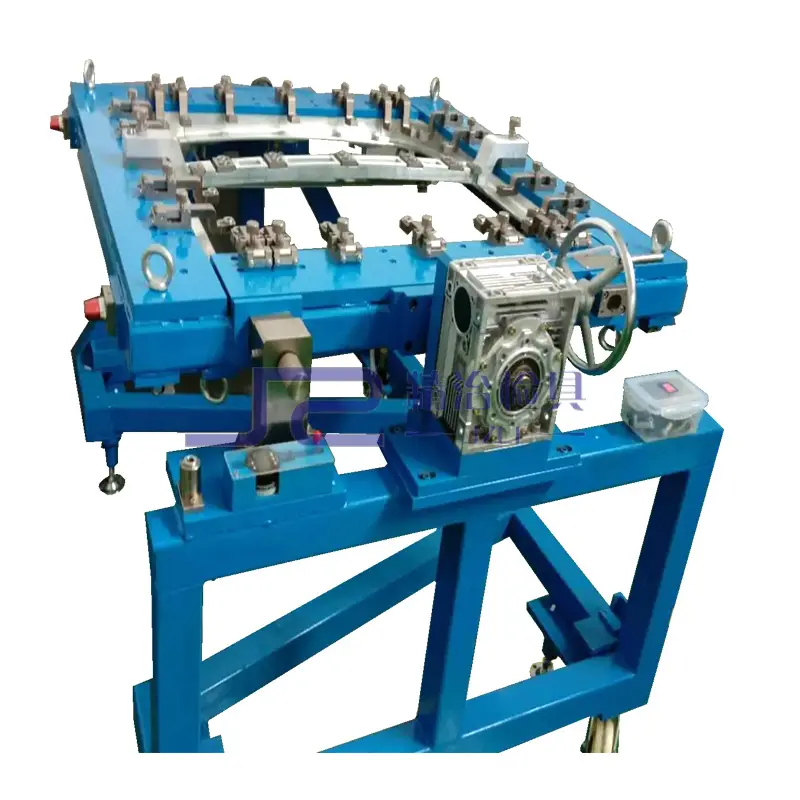

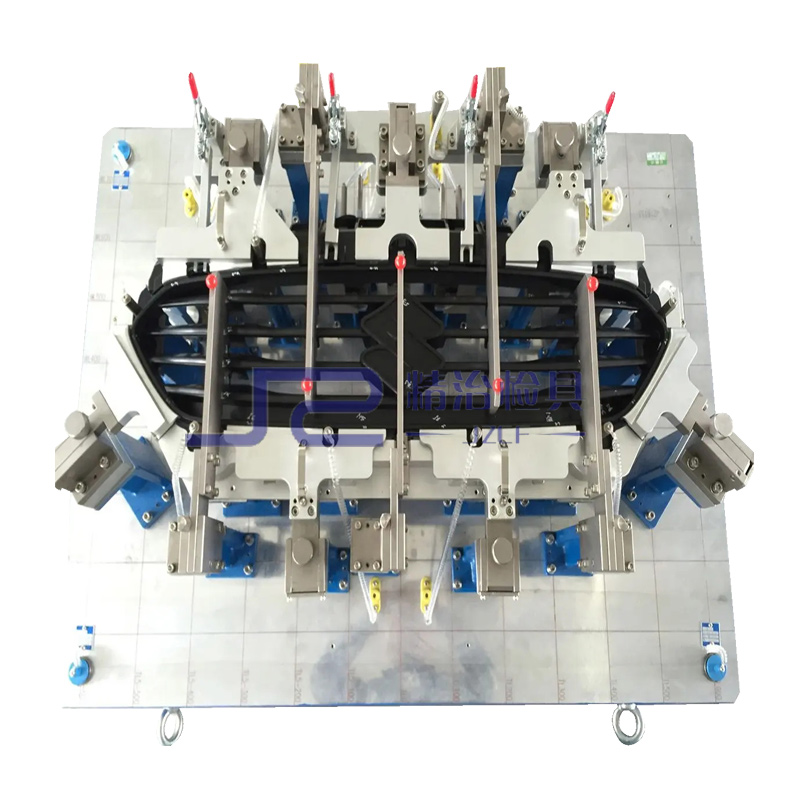

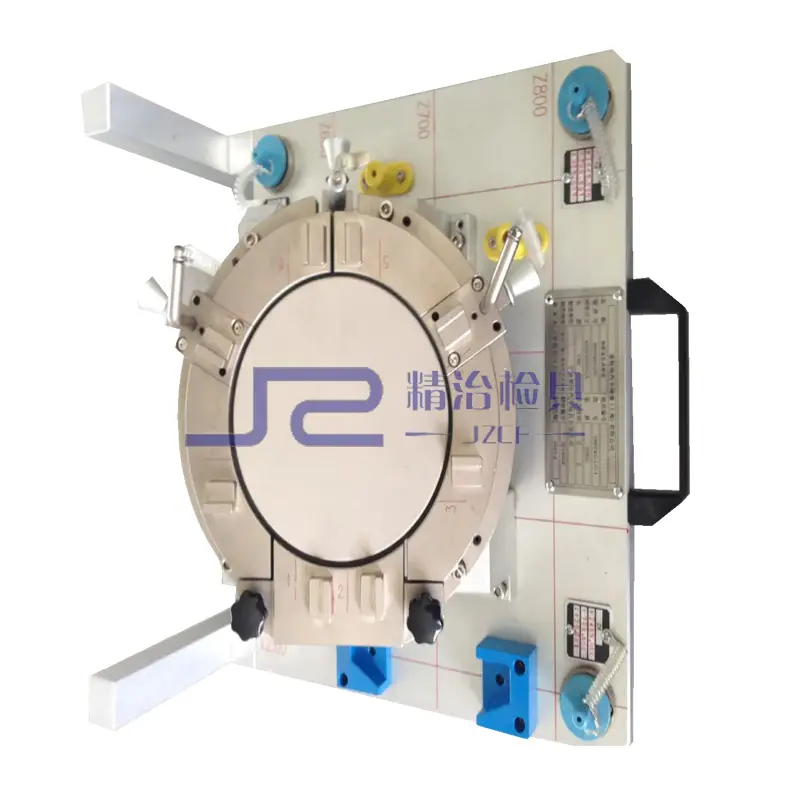

Checking fixture high-precision pipe inspection tools ensure car safety and quality

Product Description

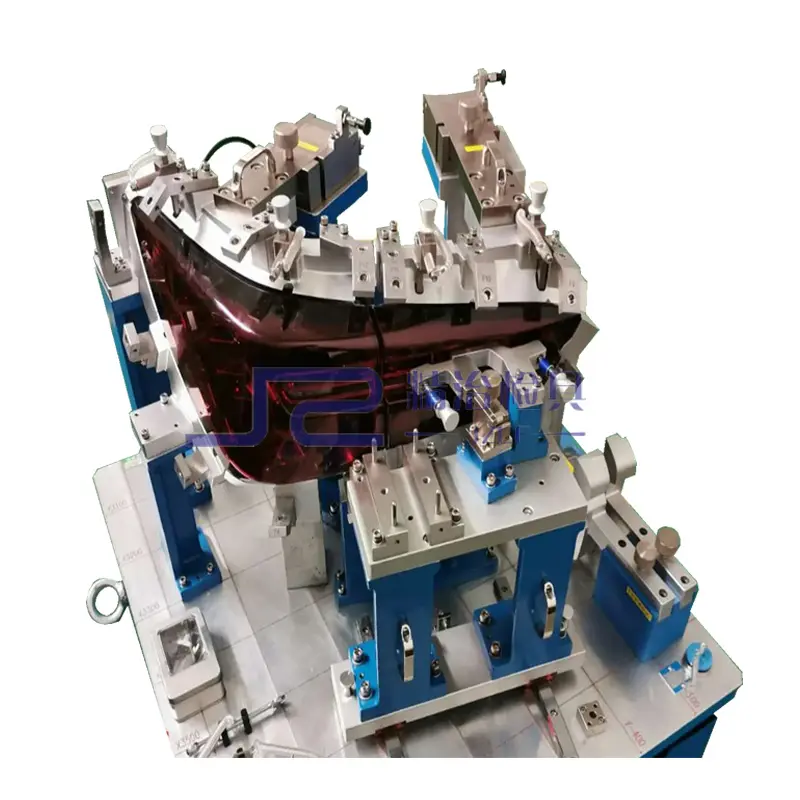

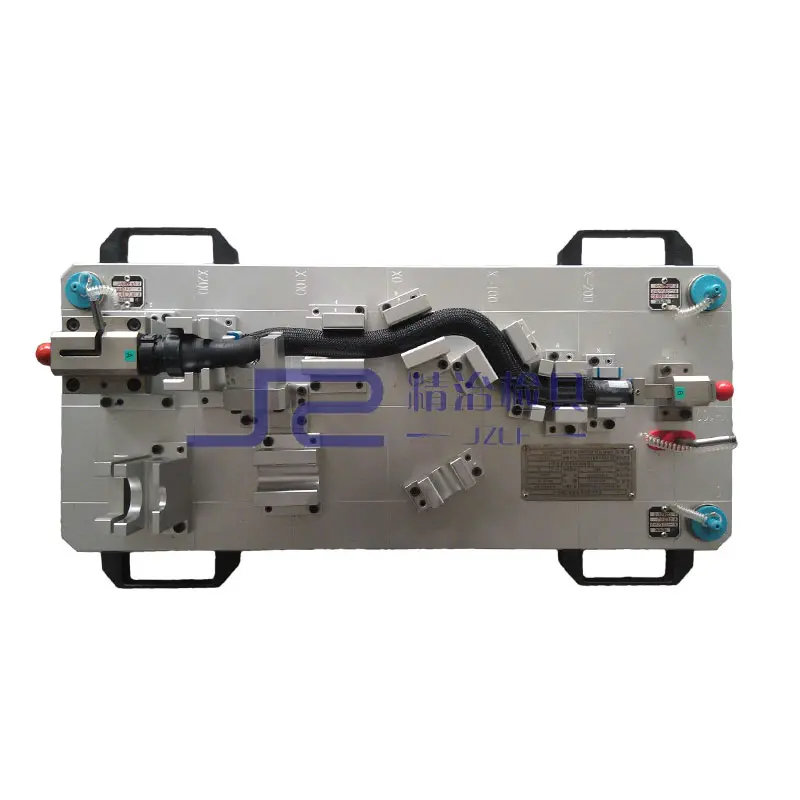

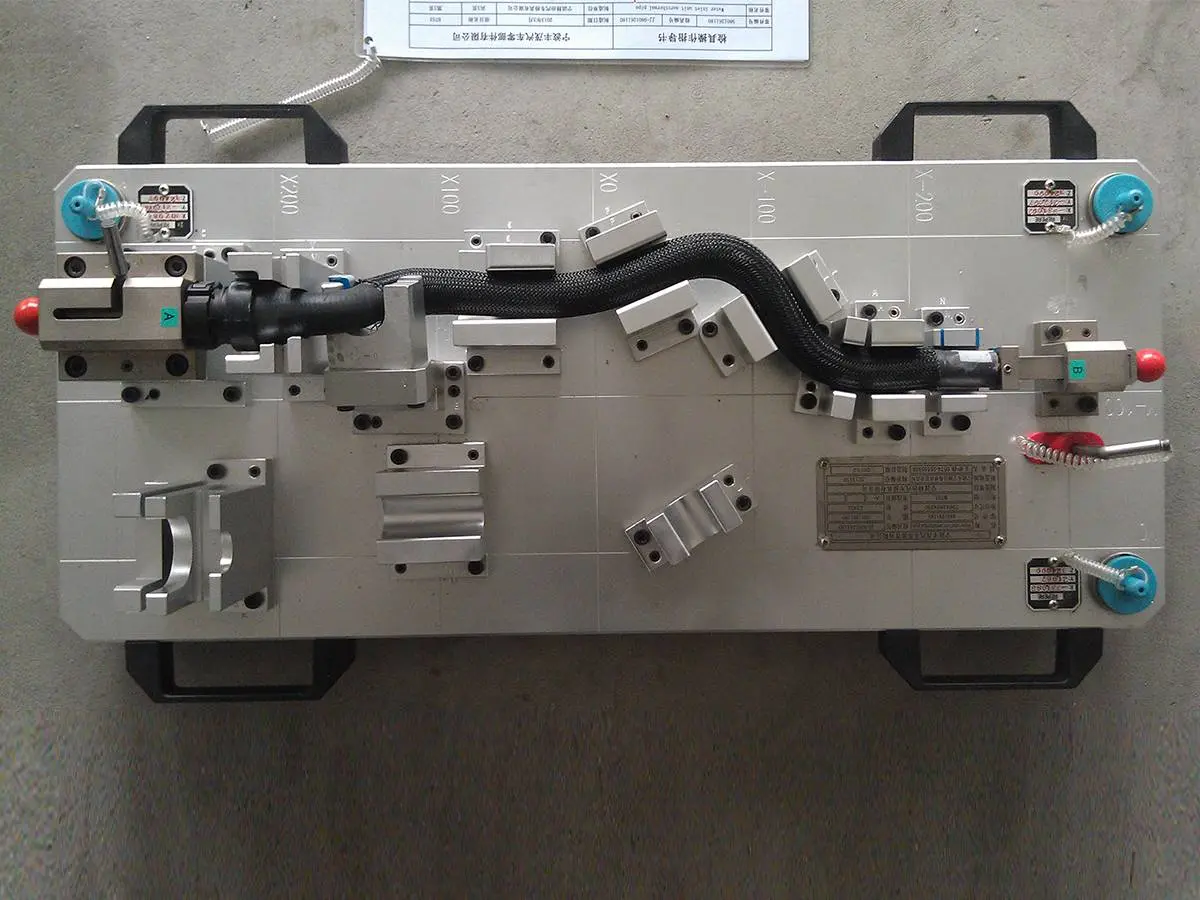

One of the main advantages of pipe inspection tools is the ability to detect potential problems during assembly, such as deformation and deformation-prone areas. This is especially important to ensure that the pipes are assembled correctly and function as expected once installed in the vehicle. By identifying deformations and weak areas early in the production process, manufacturers can take corrective measures to prevent any quality issues from affecting the final product.

In addition to quality control benefits, pipe-type inspection tools offer significant cost savings. These tools are low maintenance and designed for ease of use, allowing for an efficient and cost-effective quality control process. This is especially important in the highly competitive automotive industry, where manufacturers are constantly looking for ways to increase efficiency and reduce production costs without compromising quality.

In the production of auto parts, using inspection tools to conduct online inspections of pipeline components can quickly determine the quality of the parts produced. This real-time feedback allows manufacturers to make immediate adjustments to production processes, ensuring vehicle assembly is safe and processed quickly. Ultimately, this will improve the overall quality of auto parts and help improve vehicle reliability and performance.

By utilizing tubular inspection tools, manufacturers can not only enhance quality control processes, but also streamline production and improve the overall efficiency of the automotive manufacturing process. With their high measurement accuracy, ability to detect critical product characteristics, and cost-saving advantages, these tools are indispensable in ensuring the highest quality and precision levels for every pipe component used in automobiles.

Pipeline inspection tools are a vital asset to the automotive industry. They play a vital role in maintaining high measurement accuracy, preventing deformation and reducing maintenance costs. These tools help improve overall vehicle quality and safety by detecting critical product characteristics and potential issues during the assembly process. These tools can ensure rapid judgment of the quality status of automobile parts in production and are of immeasurable value in improving the quality control process and efficiency of the automobile manufacturing industry.

description2