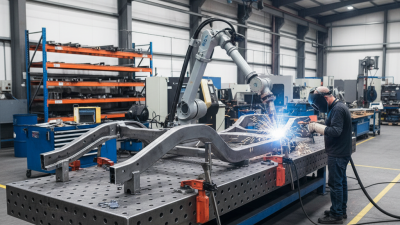

In the ever-evolving world of metalworking, the importance of precision and efficiency cannot be overstated. As expert welding engineer Dr. John Hartman succinctly puts it, “A well-designed welding fixture is the backbone of any successful welding operation.” This encapsulates the pivotal role that welding fixtures play in ensuring consistent and accurate results, ultimately enhancing productivity on the shop floor.

The right welding fixture not only streamlines the assembly process but also significantly reduces the likelihood of errors that can arise from manual handling. With the advancement of technology and manufacturing methodologies, the demand for innovative welding fixtures has surged, driving the industry to develop solutions that cater to both complex and varying welding applications.

In this article, we will explore the top 10 welding fixtures that exemplify the ideals of precision and efficiency in metalworking. By delving into their features and benefits, we aim to provide insights into how these tools can revolutionize your welding operations and contribute to a more productive and error-free environment.

Welding fixtures play a crucial role in achieving enhanced precision in metalworking, providing the stability and support needed for accurate welds. These fixtures are designed to hold workpieces in the correct position, minimizing movement during the welding process. By employing high-quality fixtures, welders can ensure consistent alignment, reduce the risk of defects, and improve overall efficiency.

When selecting welding fixtures, consider the type of welding you will be performing. Different projects may require unique fixture designs to accommodate various shapes and sizes of metal components. Additionally, integrating adjustable fixtures can greatly increase versatility, allowing for swift changes between different tasks without compromising accuracy.

Tips for optimal use of welding fixtures include maintaining a clean work area to prevent contamination and ensuring proper setup before beginning a weld. This preparation not only enhances safety but also increases the likelihood of achieving a high-quality final product. Regularly inspect your fixtures for wear and tear, as even minor damage can lead to significant inaccuracies in your work. Finally, consider the ergonomics of your workplace; an organized setup can save time and reduce physical strain, further promoting efficient metalworking practices.

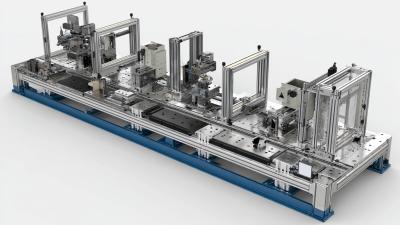

Welding fixtures play a crucial role in the metalworking industry by ensuring precision and efficiency during the welding process. There are various designs of welding fixtures, each tailored to meet specific needs in fabrication. One common type is the fixed fixture, which provides a stable platform for holding workpieces in place. These fixtures are often designed with specific contours or clamps to secure components firmly, preventing movement that could lead to misalignment during welding. Fixed fixtures are particularly useful in high-volume production, where consistency is paramount.

Another popular design is the adjustable fixture, which allows for flexibility in accommodating different workpiece sizes and configurations. These fixtures typically include movable parts that can be repositioned or reconfigured, enabling manufacturers to adapt quickly to varying production demands without the need for extensive tool changes. Additionally, modular fixtures are gaining traction, as they consist of interchangeable components that can be assembled in multiple configurations. This versatility not only streamlines the welding setup but also enhances the ability to perform various welding tasks efficiently and accurately. By understanding these common designs, fabricators can select the most appropriate welding fixtures to optimize their processes.

Welding fixtures play a critical role in enhancing both cycle time and production efficiency within the metalworking industry. These specialized tools provide precise alignment and support during the welding process, ensuring that components are correctly positioned and securely held in place. By eliminating the risk of misalignment or movement during welding, fixtures streamline the workflow, allowing for faster and more consistent results. This reliability can significantly reduce the need for rework or adjustments after the weld, which can otherwise prolong production time and decrease output.

Moreover, the implementation of advanced welding fixtures can lead to substantial improvements in overall operational efficiency. With fixtures tailored to specific projects, the setup time for each welding operation is minimized, enabling teams to transition quickly between different tasks. Additionally, efficient fixtures can enhance worker ergonomics, reducing physical strain and allowing operators to maintain a higher level of focus and productivity. As a result, organizations can achieve a more balanced workflow, enabling them to meet production demands while maintaining high-quality standards, ultimately driving down costs and improving profitability.

When it comes to welding fixtures, the choice of materials greatly impacts their durability and performance. The most commonly used materials include steel, aluminum, and various composite materials. Steel fixtures, for instance, are known for their strength and ability to withstand high temperatures, making them ideal for heavy-duty tasks. However, they can be heavy and less portable than their aluminum counterparts, which are lighter and easier to maneuver. Aluminum fixtures offer excellent corrosion resistance and are suitable for projects where weight is a crucial factor, though they may not be as robust as steel.

In selecting the right material for your welding fixtures, consider the specific requirements of your projects. For example, if precision is critical, composite materials might be the best option due to their ability to minimize heat distortion. Moreover, these composites can offer a combination of lightweight properties and strength, making them suitable for intricate designs.

**Tip:** To enhance the lifespan of welding fixtures, ensure regular maintenance and inspection. Keeping the fixtures clean and addressing any wear and tear promptly can significantly improve their efficiency and accuracy over time. Additionally, using the right type of material based on the specific use case can drastically reduce the likelihood of failures during critical operations.

When selecting and implementing welding fixtures in metalworking operations, it's essential to prioritize precision and efficiency. A well-designed fixture can improve productivity by up to 30%, as highlighted in the "Welding Parameters and Their Effect on Fixture Design" report by the American Welding Society. By investing in high-quality fixtures, manufacturers can significantly reduce cycle times and minimize errors, leading to more consistent and reliable results.

Best practices for choosing the right welding fixture begin with a thorough assessment of the specific requirements of the project. Factors such as the type of materials, the complexity of the weld joints, and the volume of production should all influence the decision-making process. According to a survey by the Fabricators & Manufacturers Association, nearly 40% of manufacturers reported that improper fixture design led to costly rework or scrap material. By employing modular fixtures that can be easily adjusted or reconfigured, operations can adapt to changing demands while maintaining tight tolerances.

Moreover, training personnel on the proper use and maintenance of welding fixtures is crucial. A recent study indicated that companies with comprehensive training programs experienced a 25% reduction in fixture-related errors. Implementing a structured training approach ensures that team members not only understand the technical aspects of fixture usage but also contribute to the overall efficiency and quality of the welding process. Emphasizing these practices fosters a culture of continuous improvement and innovation in metalworking operations.