In the realm of modern manufacturing processes, the significance of Welding Fixture Tables is increasingly acknowledged as a catalyst for enhancing productivity and precision. According to a report by the International Organization for Standardization (ISO), manufacturing efficiency can be improved by up to 30% with the use of advanced fixture systems. Welding Fixture Tables serve as crucial tools that not only streamline operations but also ensure the repeatability and accuracy necessary for high-quality welds.

Additionally, a recent study by the American Welding Society highlights that integrating innovative fixture solutions reduces setup time by approximately 25%, allowing manufacturers to adapt swiftly to changing production demands. This flexibility is vital in today's fast-paced environment where customization and speed are paramount.

Therefore, exploring the various applications and advantages of Welding Fixture Tables can provide valuable insights for manufacturers aiming to optimize their processes and maintain a competitive edge.

Additionally, a recent study by the American Welding Society highlights that integrating innovative fixture solutions reduces setup time by approximately 25%, allowing manufacturers to adapt swiftly to changing production demands. This flexibility is vital in today's fast-paced environment where customization and speed are paramount.

Therefore, exploring the various applications and advantages of Welding Fixture Tables can provide valuable insights for manufacturers aiming to optimize their processes and maintain a competitive edge.

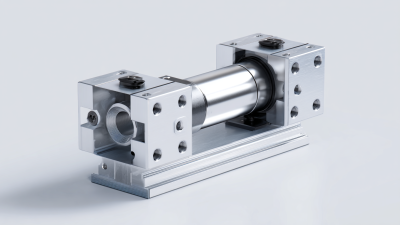

Welding fixture tables are essential components in manufacturing settings, serving as the backbone for precise fabrication processes. Their primary function is to provide a stable and adjustable platform that facilitates the accurate positioning and assembly of parts prior to welding. This is crucial in ensuring that the final product adheres to strict quality standards and minimizes the risk of errors during production. By utilizing these tables, manufacturers can reduce setup times and improve overall efficiency, leading to quicker turnaround times and enhanced productivity.

In addition to their role in precision, welding fixture tables contribute significantly to safety and consistency in manufacturing. A well-designed fixture not only helps in maintaining dimensional accuracy but also reduces the chances of component misalignment, which can result in structural weaknesses. Furthermore, these tables can accommodate various workpieces, making them versatile solutions that adapt to the specific needs of different projects. With the increasing complexity of modern manufacturing demands, the importance of welding fixture tables has become ever more pronounced, as they enable companies to meet both quality expectations and operational efficiency simultaneously.

| Feature | Importance | Application Areas | Material Compatibility | Customization Options |

|---|---|---|---|---|

| Adjustable Height | Enhances ergonomics and accessibility | Automotive, Aerospace | Steel, Aluminum | Height adjustment mechanisms |

| Modular Design | Flexible for various projects | Construction, Shipbuilding | Stainless Steel, Cast Iron | Interchangeable components |

| Weld Positioning Systems | Improves joint quality and efficiency | Manufacturing, Heavy Equipment | Carbon Steel, Alloys | Rotational jigs, clamps |

| Integration with Automation | Streamlines production processes | Electronics, Robotics | Plastic Composites, Mild Steel | Robotic arms compatibility |

| Durable Surface Finishes | Resistant to wear and tear | General Manufacturing, Aerospace | Various Metals | Coatings, anodizing |

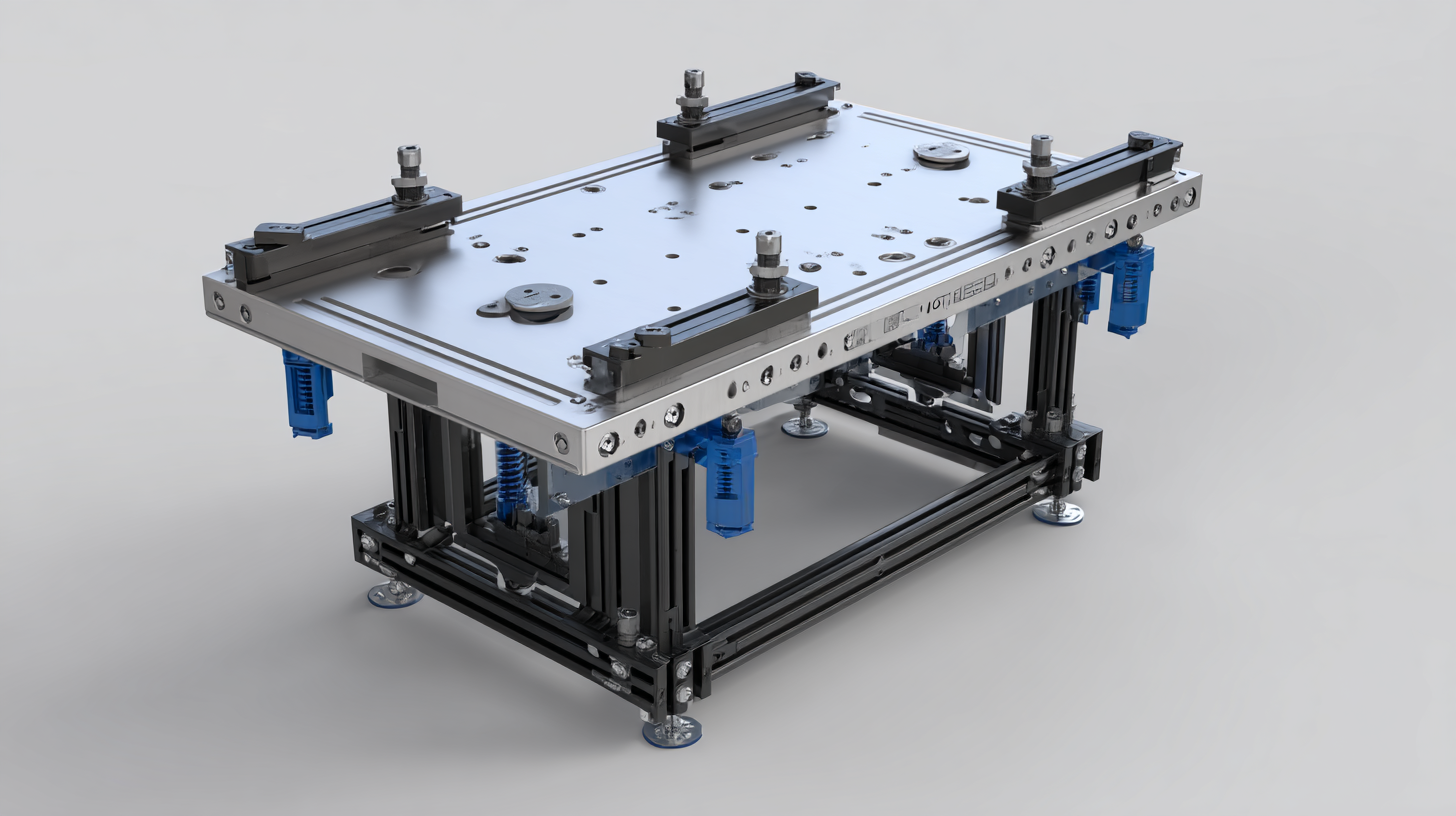

When selecting the right welding fixture table for your production needs, it's essential to consider the specific requirements of your manufacturing processes. According to a report by the American Welding Society, approximately 60% of manufacturers cite precision and flexibility as critical factors in their welding setups. This highlights the necessity of investing in a fixture table that can accommodate various projects and workflows effectively.

A suitable welding fixture table should offer several key features, such as adjustability, robust material construction, and adaptability to different welding techniques. For instance, tables made from high-quality steel can ensure durability and stability, while modular designs allow for quick alterations to meet the production demands. A study conducted by the Fabricators and Manufacturers Association revealed that businesses utilizing adjustable fixture tables reported a 25% increase in production efficiency, demonstrating the value of customization in welding processes.

Furthermore, considering the size and layout of your production area is crucial. A compact, yet versatile fixture table can save valuable floor space while maximizing productivity. As reported in the Manufacturing Industry Trends 2023, organizations that tailored their workspaces with the right equipment experienced a notable decrease in operational delays, emphasizing the importance of choosing the best welding fixture table for your specific manufacturing environment.

The design of custom welding fixture tables plays a pivotal role in enhancing efficiency within modern manufacturing processes. By tailoring these tables to specific applications, manufacturers can significantly improve workflow and precision. Customization allows for the integration of unique features such as adjustable heights, modular components, and specific geometries that accommodate diverse welding tasks. Such adaptability ensures that the welder can work at optimal angles, reducing fatigue and increasing productivity.

Moreover, investing in custom welding fixture tables streamlines the assembly process by minimizing setup times and ensuring that components are securely held in place during welding. This not only enhances the quality of the welds but also reduces the likelihood of defects and rework. Implementing advanced materials, such as lightweight alloys or magnetic surfaces, can further enhance the performance of these fixtures. As manufacturers strive for competitiveness and efficiency, the significance of bespoke welding fixture tables becomes evident, paving the way for innovation and excellence in production.

Welding fixture tables are essential components in modern manufacturing, ensuring precision and efficiency during the welding process. To maximize their lifespan and functionality, regular maintenance is crucial. This involves routine inspections to identify wear and tear, as well as meticulous cleaning to prevent any buildup of debris or contaminants that could affect weld quality. Applying protective coatings can also shield the surfaces from rust and damage, extending the table's usable life significantly.

Upgrading welding fixture tables can further enhance their performance. Incorporating modular designs allows for flexibility in assembly configurations, catering to different projects without the need for extensive modifications. Adding features like adjustable height mechanisms or integrated clamping systems can streamline operations, improving both safety and productivity. By investing in regular maintenance and thoughtful upgrades, manufacturers can ensure that their welding fixture tables remain reliable tools that adapt seamlessly to evolving production requirements.

This chart represents the average lifespan and maintenance frequency of welding fixture tables across different manufacturing processes, showcasing their versatility and importance in maintaining production efficiency.

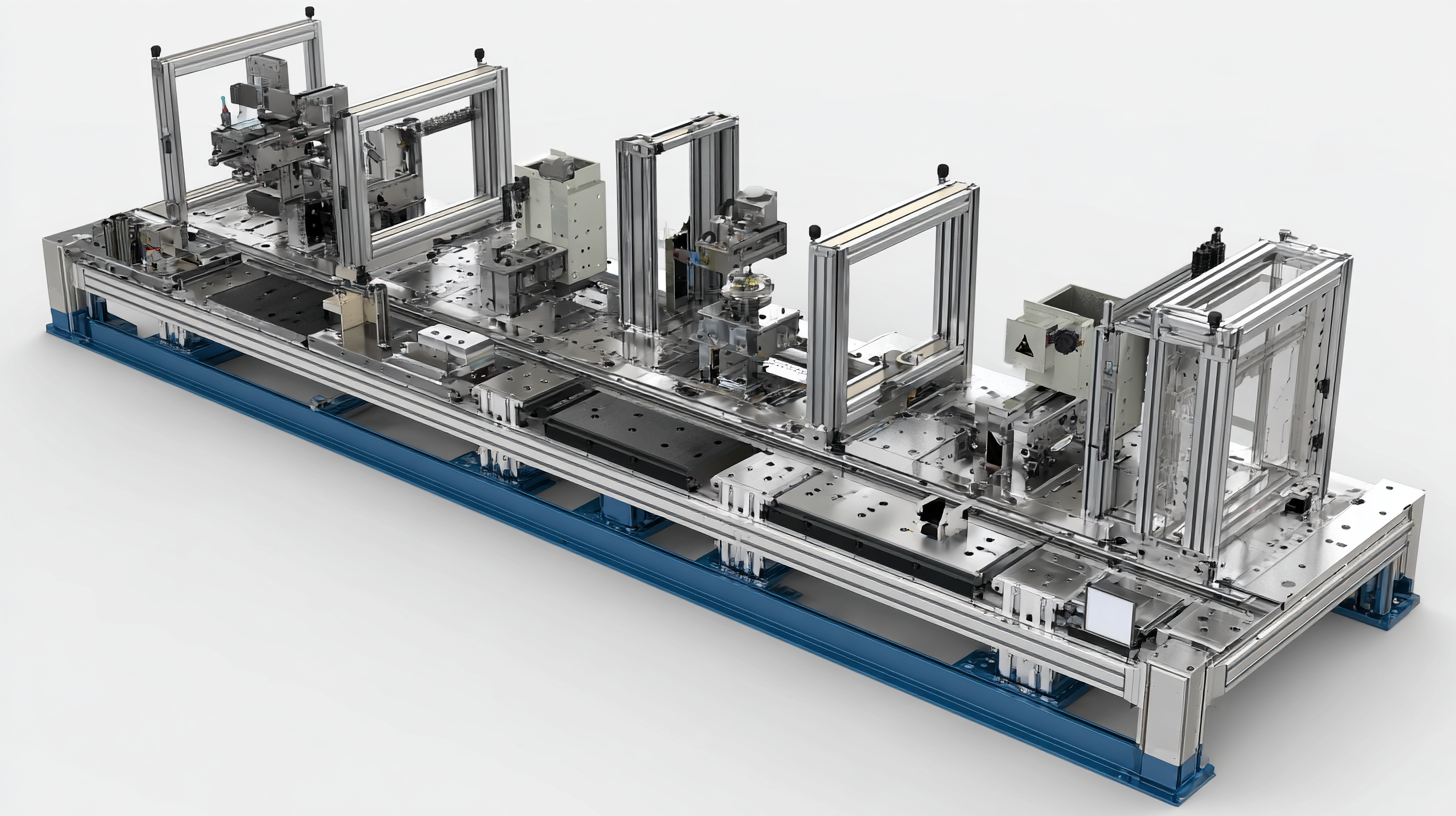

The integration of advanced technologies with welding fixture tables is revolutionizing modern manufacturing processes. By incorporating automation and digital technologies, manufacturers can enhance the precision and efficiency of welding operations. For instance, the use of computer numerical control (CNC) systems allows for highly accurate positioning and repeatability, ensuring that each weld meets stringent quality standards. Additionally, integrating sensors and real-time monitoring systems into welding fixtures enables operators to track performance metrics and detect anomalies during the welding process, significantly minimizing the risk of defects.

Moreover, welding fixture tables equipped with augmented reality (AR) and virtual reality (VR) technologies are transforming the way technicians are trained and processes are executed. With AR and VR tools, learners can visualize complex weld paths and understand spatial relationships more intuitively, resulting in faster onboarding and reduced error rates. Furthermore, these technologies facilitate better collaboration among teams, allowing remote experts to assist on-site workers by overlaying critical information onto the physical workspace. This convergence of welding fixture tables with cutting-edge technologies not only boosts productivity but also fosters innovation in the manufacturing sector.