In the realm of precision measurement, the Vernier Caliper stands out as an indispensable tool across various industries. Designed to provide accurate readings with remarkable ease, its versatility extends from manufacturing and engineering to medical applications and beyond. This blog delves into the real-world applications of the Vernier Caliper, highlighting its critical role in enhancing measurement precision. We explore how this ingenious device empowers professionals to achieve the exactitude required in tasks ranging from intricate mechanical assemblies to delicate surgical procedures.

Alongside practical examples, we’ll share valuable tips for effectively employing Vernier Calipers, ensuring that users can unlock their full potential. Join us as we unlock the precision that this remarkable tool brings to diverse fields, illustrating not only its functionality but also its paramount importance in modern-day practices.

In the world of manufacturing, precision measurement is crucial for ensuring quality and efficiency. Among the tools available, vernier calipers stand out due to their ability to provide accurate readings for a variety of applications. This blog highlights the top five vernier calipers that excel in precision measurement, helping manufacturers choose the right tool for their needs.

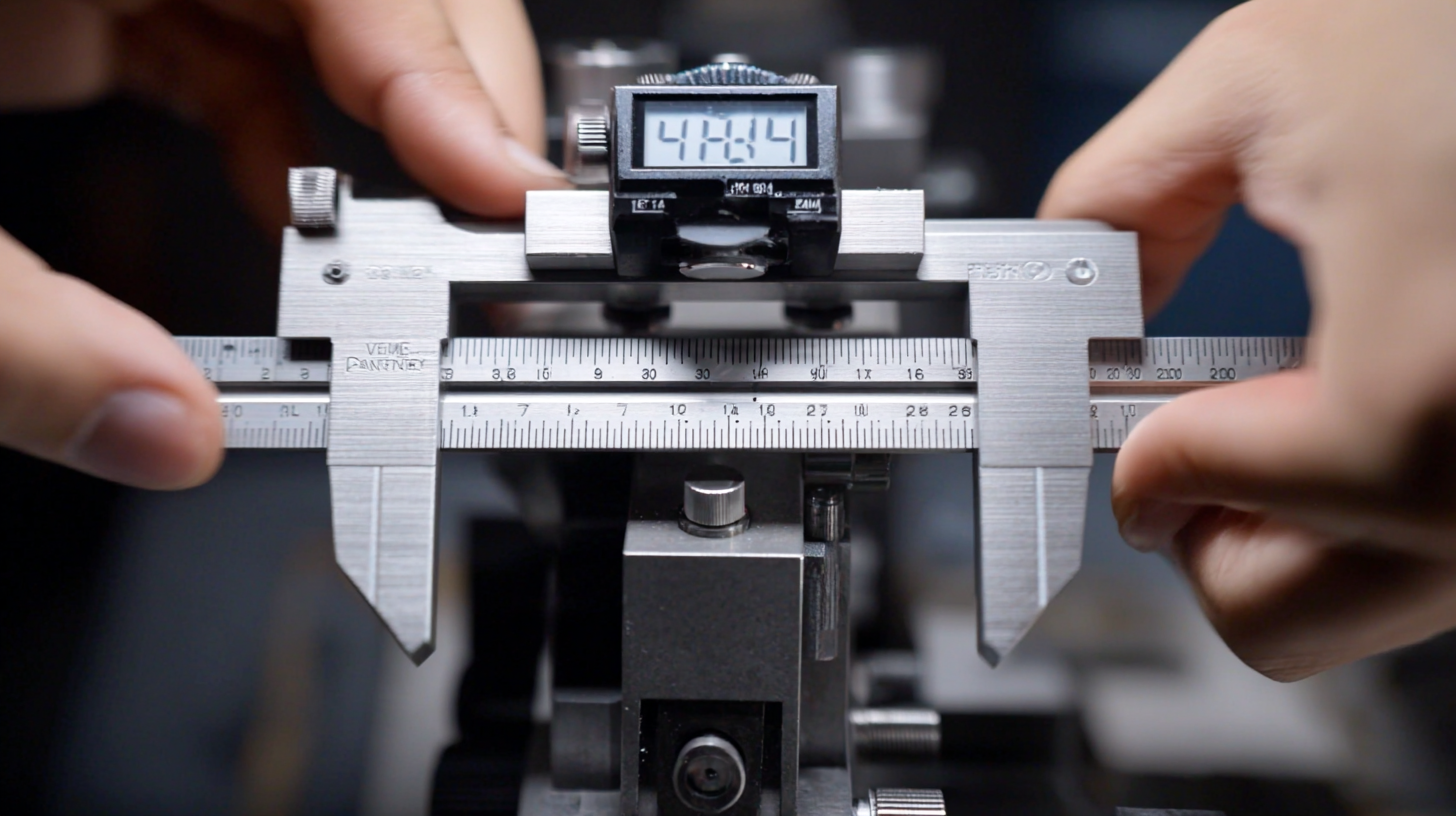

When selecting a vernier caliper, consider factors such as material construction and measurement capabilities. Stainless steel calipers offer durability and corrosion resistance, while digital versions provide easy readability and quick data recording. Some top models include the Mitutoyo 500 Series, known for its robust design and high accuracy, or the Starrett 123 Series, which boasts a fine adjustment thumbroll for precise measurements.

Tips for using vernier calipers effectively include ensuring the instrument is clean and calibrated before use, and practicing the correct method of reading the scale to avoid parallax errors. Additionally, it's beneficial to take multiple measurements and average them to enhance accuracy. By choosing the right caliper and employing these tips, manufacturers can significantly improve precision in their operations.

In the realm of automotive engineering, precision is paramount. Vernier calipers play a crucial role in ensuring that every measurement is accurate, allowing engineers to maintain high standards in vehicle manufacturing and design. These tools provide measurements down to the millimeter and fraction of a millimeter, enabling competent evaluation of components, such as engine parts and chassis designs, where even the slightest deviation can affect performance and safety.

A useful tip for engineers using vernier calipers is to always double-check settings before taking measurements. Ensuring the tool is properly zeroed out can prevent costly errors in design and assembly. Additionally, maintaining the calipers in a clean and calibrated state guarantees reliability across various measurements, safeguarding the integrity of the automotive components.

Another important consideration is the measurement technique. When using vernier calipers, it’s essential to align the measuring jaws correctly with the object being measured, applying gentle pressure to avoid deformation. This technique not only enhances accuracy but also extends the life of the tool. By implementing these practices, automotive engineers can harness the full potential of vernier calipers, elevating their engineering projects with precision and confidence.

| Industry | Application | Precision Level | Typical Measurement Range |

|---|---|---|---|

| Automotive Engineering | Brake Component Measurement | 0.02 mm | 0-200 mm |

| Manufacturing | Machined Part Inspection | 0.01 mm | 0-150 mm |

| Aerospace | Component Tolerance Checking | 0.005 mm | 0-300 mm |

| Electronics | Circuit Board Measurements | 0.02 mm | 0-50 mm |

| Construction | Material Thickness Measurements | 0.1 mm | 0-100 mm |

Vernier calipers are indispensable tools in the medical field, offering unparalleled precision in measurement that is critical for patient care and treatment. One unique application is in the fitting of prosthetics. Medical professionals rely on the accuracy of vernier calipers to measure limb dimensions, ensuring that prosthetic devices fit comfortably and functionally for patients. This precise fitting can significantly enhance a patient's mobility and overall quality of life.

Another significant application of vernier calipers is in the field of dentistry. Dentists use these tools to measure the exact dimensions of dental appliances, such as crowns and braces. Accurate measurements are essential to guarantee that these appliances fit correctly and do not harm the patient. Furthermore, in surgical settings, vernier calipers help in measuring tissue thickness and other critical parameters, aiding surgeons in making informed decisions during procedures. These examples underscore the vital role that vernier calipers play in various medical applications, highlighting their importance in delivering high-quality healthcare.

In the realm of education, precision tools like vernier calipers play a pivotal role in enhancing students' understanding of measurement and scientific concepts. According to a report by the National Science Foundation, hands-on learning experiences can improve student performance in STEM fields by up to 20%. Vernier calipers, with their ability to measure internal and external dimensions with accuracy up to 0.02 mm, provide an ideal medium for students to engage in practical measurements, fostering a deeper grasp of geometrical and mathematical principles.

Schools are incorporating vernier calipers into various subjects beyond physics, including art and design, where precise measurements are critical. A study published in the Journal of Engineering Education highlighted that students who used vernier calipers during design projects demonstrated a 30% increase in project accuracy compared to those relying solely on basic measuring tools. Moreover, integrating these precision instruments into the curriculum helps students prepare for advanced studies and careers in engineering and technology, where precision is paramount. Thus, vernier calipers not only enhance educational outcomes but also pave the way for future innovators in various industries.

Vernier calipers are essential tools that enhance quality control across various industries, ensuring precise measurements that ultimately contribute to product reliability. In the manufacturing sector, for example, a report from the National Institute of Standards and Technology (NIST) indicates that inaccuracies in measurement can lead to production errors costing companies over $1.5 trillion annually. Utilizing vernier calipers allows manufacturers to achieve tolerances as tight as ±0.02 mm, significantly reducing the risk of defects in components.

In the medical device industry, precision is paramount. According to data from the FDA, nearly 80% of medical device recalls are related to design flaws, which can arise from improper measurements. By integrating vernier calipers into their quality control processes, manufacturers can ensure that components meet stringent regulatory standards and specifications, thus minimizing potential recalls. Furthermore, the aerospace sector, where safety is non-negotiable, benefits immensely from the accuracy provided by vernier calipers. A study from the Aerospace Industries Association (AIA) found that stringent quality control, inclusive of precise measurements, can enhance the safety and performance of aerospace products, resulting in improved operational efficiency and reduced liability.