In the rapidly evolving landscape of modern manufacturing, precision and efficiency are paramount, underscoring the critical role of CMM measurement (Coordinate Measuring Machine). According to a recent report by Grand View Research, the global CMM market is projected to reach $3.55 billion by 2025, driven by the increasing demand for high-quality manufacturing processes across various industries. CMM measurement offers unparalleled accuracy in dimensional inspections, ensuring that components meet stringent specifications and enhancing overall production quality. As manufacturers embrace smart factories and advanced technologies, integrating CMM measurement systems not only streamlines operations but also plays a crucial role in maintaining competitiveness in a market that increasingly prioritizes precision and reliability. Understanding the nuances of CMM measurement will empower manufacturers to optimize their processes, minimize errors, and ultimately drive better business outcomes.

In today’s competitive landscape, the significance of Coordinate Measuring Machine (CMM) measurement in precision manufacturing cannot be overstated. With the growing complexity of manufacturing processes, industries are increasingly turning to CMM technology to ensure it meets stringent tolerances and quality standards. According to a report by MarketsandMarkets, the global CMM market is projected to reach $2.1 billion by 2025, reflecting an annual growth rate of 6.5%. This surge is driven by advancements in automation and the necessity for enhanced quality control in sectors such as aerospace, automotive, and electronics.

CMMs offer manufacturers the ability to perform meticulous measurements that are critical for product performance and reliability. For instance, a study by the National Institute of Standards and Technology (NIST) highlighted that implementing CMMs can reduce inspection time by up to 50%, thus allowing for faster production cycles. Furthermore, the precision delivered by CMMs substantially minimizes the risk of defects, which, according to the American Society for Quality, can save companies between 10-20% of their total production costs. As manufacturers strive for leaner operations and higher quality outputs, CMM technology represents a vital investment in achieving operational excellence.

| Measurement Parameter | Importance Level | Typical Tolerance (mm) | Application Area | Frequency of Measurement |

|---|---|---|---|---|

| Dimensional Accuracy | High | ±0.01 | Aerospace Components | Daily |

| Surface Finish | Medium | Ra 0.8 | Automotive Parts | Weekly |

| Geometric Dimensioning and Tolerancing (GD&T) | High | ±0.02 | Medical Devices | Monthly |

| Roundness | Medium | ±0.005 | Precision Gearing | Bi-weekly |

| Flatness | Medium | ±0.01 | Electronic Components | Monthly |

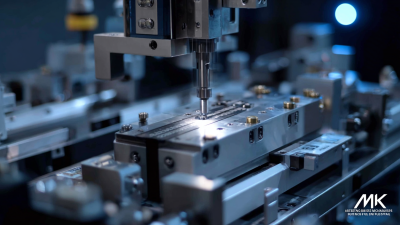

CMM, or Coordinate Measuring Machine, plays a vital role in modern manufacturing processes by ensuring

precision and quality control. There are several types of CMM systems that cater to different industry needs.

The most common types include contact CMMs, optical CMMs, and laser CMMs.

Contact CMMs use mechanical probes to touch the surface of the object, allowing for highly accurate measurements. These are widely used in industries that require

stringent tolerances, such as aerospace and automotive manufacturing.

On the other hand, optical CMMs employ non-contact methods, utilizing lasers or cameras to measure objects.

This type is particularly beneficial for delicate components or materials that cannot withstand physical contact,

frequently found in electronics or medical device manufacturing.

Laser CMMs, while similar to optical systems, utilize laser beams to scan and record data, producing

detailed three-dimensional information about the part being measured. Each type of CMM serves specific applications, making them

essential tools for achieving efficiency and precision in the manufacturing sector.

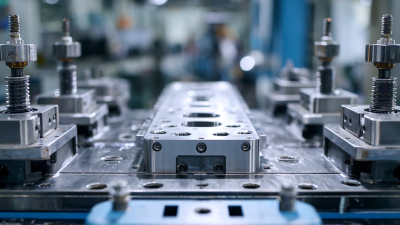

Integrating Coordinate Measuring Machine (CMM) measurement into the production workflow is a crucial step for modern manufacturers striving for precision and efficiency. By embedding CMM measurements directly into production lines, companies can significantly reduce the risk of defects. This proactive approach allows for real-time adjustments, ensuring that products meet exact specifications before moving further down the line.

Tips for successful integration include training your staff on CMM operation and interpretation of results. A well-informed team can utilize CMM data to make informed decisions quickly, which is essential in a fast-paced manufacturing environment. Additionally, consider scheduling regular maintenance for your CMM equipment. Keeping measurement tools in optimal condition minimizes downtime and maintains measurement accuracy.

Another important aspect is to establish a feedback loop between quality assurance and production teams. This collaboration allows for immediate response to any discrepancies found during measurements. By fostering an atmosphere of continuous improvement, manufacturers not only maintain high quality but also enhance overall productivity.

Maximizing the efficiency of Coordinate Measuring Machines (CMMs) in modern manufacturing processes is vital for achieving high precision and productivity. One of the best practices for utilizing CMMs involves regular calibration and maintenance. By ensuring that the machine is accurately calibrated, manufacturers can avoid costly discrepancies in measurements that may lead to product defects or rework. Additionally, investing in routine maintenance checks helps to extend the lifespan of the CMM while minimizing downtime, ultimately resulting in a smoother production flow.

Maximizing the efficiency of Coordinate Measuring Machines (CMMs) in modern manufacturing processes is vital for achieving high precision and productivity. One of the best practices for utilizing CMMs involves regular calibration and maintenance. By ensuring that the machine is accurately calibrated, manufacturers can avoid costly discrepancies in measurements that may lead to product defects or rework. Additionally, investing in routine maintenance checks helps to extend the lifespan of the CMM while minimizing downtime, ultimately resulting in a smoother production flow.

Another key practice for optimizing CMM usage is incorporating advanced software solutions. Modern CMMs are equipped with sophisticated software that can streamline measurement processes, making it easier to collect and analyze data. Utilizing automation tools can significantly reduce manual errors and enhance data management, allowing for more insightful analysis of trends and production performance. Furthermore, training staff on best practices for both the hardware and software components is essential. An educated workforce can leverage these technologies effectively, ensuring that the full capabilities of CMMs are harnessed to drive manufacturing excellence.

The CMM (Coordinate Measuring Machine) market is expected to experience significant growth, with forecasts projecting its size to exceed several billion dollars by 2026. As manufacturing processes become increasingly intricate, the demand for precise measurement solutions is paramount. The integration of advanced technologies, including automation and the Internet of Things (IoT), enhances the efficiency and accuracy of CMMs, making them indispensable in modern production environments. These advancements not only improve measurement capabilities but also reduce turnaround times, allowing manufacturers to meet rising consumer demands more effectively.

Tip: When considering the implementation of CMM technology, it's crucial to assess how automation can streamline your manufacturing processes. Investing in integrated solutions that combine CMMs with IIoT systems can yield both time and cost savings.

Future trends indicate that CMMs will evolve further, incorporating artificial intelligence to facilitate predictive maintenance and optimize operational workflows. This shift will enable manufacturers to maintain higher quality standards while adapting to the dynamic nature of the market. Embracing these technologies can position businesses for long-term success.

Tip: Regularly update your training programs to ensure that employees are proficient in the latest CMM technologies. This investment in skill development can enhance overall productivity and minimize measurement errors.