In recent years, the demand for Prototype Aluminum Casting has surged, driven by its critical role in the rapid prototyping and manufacturing sectors. According to industry reports, the global aluminum casting market is projected to reach USD 78 billion by 2027, with prototype casting accounting for a significant segment due to its versatility and efficiency. The adoption of advanced casting technologies, such as 3D printing and CNC machining, has further enhanced the capabilities of prototype aluminum casting, enabling quicker turnaround times and improved material properties. This article explores the key advantages of prototype aluminum casting, such as reduced time-to-market and cost-effectiveness, while also highlighting industry insights that underscore its transformative impact on product development and innovation. As manufacturers seek to stay competitive in an ever-evolving marketplace, understanding the nuances of prototype aluminum casting becomes essential for unlocking new innovations and optimizing production processes.

The efficiency of prototype aluminum casting is crucial for the automotive sector, particularly as the industry moves towards more sustainable and lightweight solutions. One key strategy to enhance efficiency is the adoption of advanced lightweight materials, which can significantly impact the design and performance of vehicles. Innovations in aluminum alloys, combined with high-strength steels, provide manufacturers with the ability to produce components that meet both safety and environmental standards.

Furthermore, as the European automotive casting market continues to grow, reaching an expected USD 35.22 billion by 2033, manufacturers must leverage cutting-edge technologies and techniques in their casting processes. Implementing automation and advanced software solutions can optimize production cycles and minimize waste, leading to a more sustainable and cost-effective operation. By focusing on these strategies, companies can not only streamline their prototyping processes but also improve the overall quality and weight efficiency of their automotive products.

| Feature | Key Advantage | Efficiency Strategy | Industry Insight |

|---|---|---|---|

| Rapid Prototyping | Reduces Time to Market | Utilize Advanced 3D Printing Techniques | Growing Demand for Faster Turnarounds |

| Design Flexibility | Allows Complex Geometries | Implement Design for Manufacturability (DFM) | Increasing Need for Customization |

| Material Efficiency | Minimizes Waste | Optimize Material Use During Casting | Sustainability Trends in Manufacturing |

| Cost Reduction | Lowers Overall Production Costs | Leverage High-Speed Machining | Competitive Market Pressures |

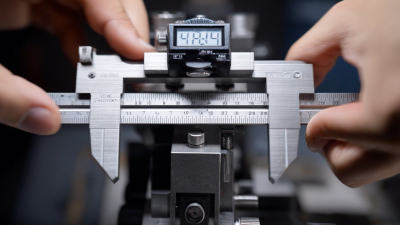

| Quality Control | Ensures High Material Integrity | Adopt Real-Time Monitoring Systems | Focus on Reducing Defects |

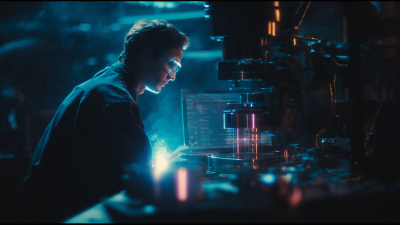

Advanced technologies play a pivotal role in revolutionizing aluminum prototype casting, bringing significant efficiency and precision to the manufacturing process. Automated systems and cutting-edge software enable manufacturers to streamline operations, from initial design to final production. Technologies such as computer-aided design (CAD) and simulation tools allow for real-time adjustments and optimizations, minimizing the time required for prototyping and reducing the risk of errors. This level of integration not only accelerates the development cycle but also enhances the overall quality of the cast prototypes.

In addition to software advancements, innovative materials and techniques, such as 3D printing and robotic automation, are transforming the landscape of aluminum casting. These technologies facilitate the creation of complex geometries that were previously challenging or impossible to achieve with traditional methods. Moreover, 3D printing can significantly cut down lead times and costs, making it feasible for companies to produce small batches of prototypes with high precision. As industries continue to adopt these innovations, the potential for enhanced performance and reduced waste in aluminum prototype casting becomes clearer, paving the way for more sustainable manufacturing practices.

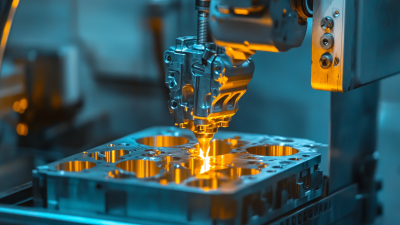

Recent innovations in aluminum casting technology are reshaping key industries, particularly automotive manufacturing. At the AICE 2025 SMM Aluminum Industry Conference, research showcased advancements such as the frozen sand mold casting technique, which facilitates the production of complex, thin-walled aluminum alloy components. This green casting method substitutes traditional resin binders with water, enhancing environmental sustainability while maintaining precision, with machining errors limited to ±0.25 mm.

Recent innovations in aluminum casting technology are reshaping key industries, particularly automotive manufacturing. At the AICE 2025 SMM Aluminum Industry Conference, research showcased advancements such as the frozen sand mold casting technique, which facilitates the production of complex, thin-walled aluminum alloy components. This green casting method substitutes traditional resin binders with water, enhancing environmental sustainability while maintaining precision, with machining errors limited to ±0.25 mm.

The cost-benefit analysis of these innovations reveals significant potential savings and efficiency improvements for manufacturers. As industries aim to streamline production processes, the adoption of single aluminum components—such as those used in megacasting—eliminates the need for multiple welded parts, thereby reducing material waste and labor costs. Additionally, the differential pressure casting market is expected to witness substantial growth, indicating a rising demand for advanced casting machinery that supports these innovative practices. The aluminum casting sector is poised for expansion, driven by technological advancements and a clear focus on cost-effective solutions.

The prototype aluminum casting industry is increasingly leaning towards sustainability practices to mitigate environmental impacts. According to a recent report from the Aluminum Association, more than 75% of aluminum produced since the 1880s is still in use today, making aluminum one of the most recyclable materials. This longevity is critical as companies adopt closed-loop systems, reducing waste and maximizing resource efficiency. Moreover, implementing energy-efficient casting techniques can reduce carbon footprints by up to 50%, highlighting the dual benefits of sustainability and cost savings.

To enhance sustainability in aluminum casting, companies can adopt several key strategies. Tip: Consider integrating recycled aluminum into your manufacturing processes, as it requires only 5% of the energy needed to produce primary aluminum. Moreover, investing in modern technologies, such as additive manufacturing and smart casting techniques, not only streamlines the production process but also minimizes material wastage. According to a study by the International Aluminum Institute, these practices can result in a 20% reduction in raw material usage, showcasing a path toward more eco-friendly operations.

As the industry evolves, staying informed about sustainable practices will be essential for competitive advantage. Tip: Regularly evaluate and update your sustainability goals to align with industry standards and regulations, ensuring continual improvement and innovation in your operations.

The aluminum casting industry is witnessing significant growth, driven by the increasing demand for lightweight materials in construction and automotive sectors. The market for aluminum casting solutions is projected to expand from $51.017 billion in 2024 to $72.439 billion by 2031, reflecting a compound annual growth rate (CAGR) of 5.14%. This shift towards lightweight materials is largely attributed to the construction industry's focus on enhancing structural integrity and energy efficiency while minimizing costs.

Moreover, the automotive sector is also poised for considerable advancements, particularly with components like camshafts, where the market is expected to grow from $4.6 billion in 2024, achieving a CAGR of 5.4% from 2025 to 2034. This growth is propelled by the rising demand for high-performance engines and an increase in vehicle production. As industries continue to embrace aluminum casting, it is clear that these innovations hold the key to meeting modern manufacturing needs while adhering to sustainability and efficiency standards.