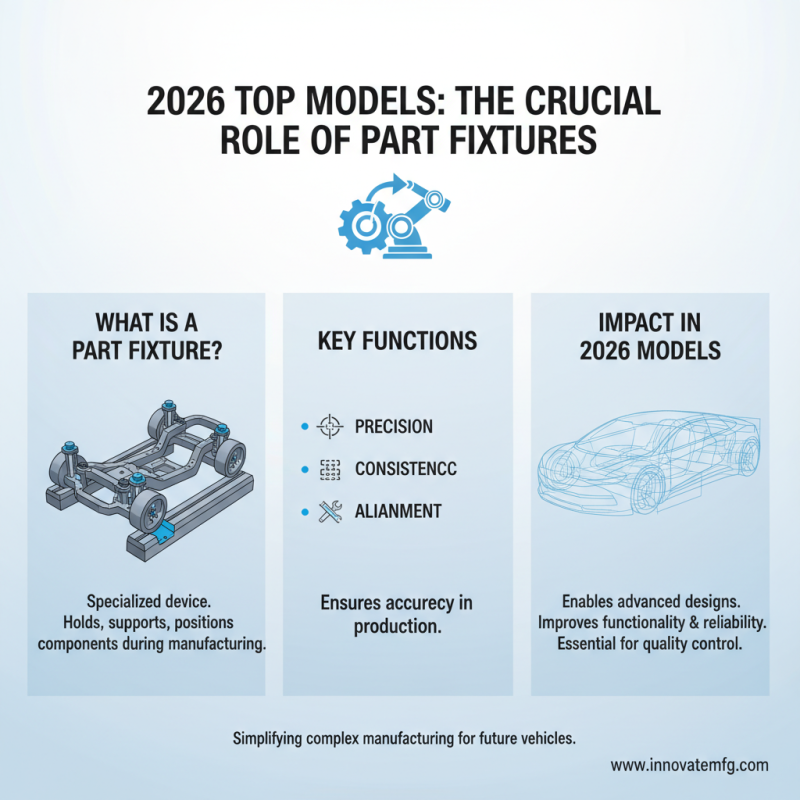

In the evolving landscape of automotive manufacturing, the concept of a "Part Fixture" has gained prominence. Renowned industry expert Dr. Jane Thompson states, "Effective Part Fixtures are crucial for maintaining precision in model production." Understanding their role in top models of 2026 is essential for navigating the complexities of modern assembly lines.

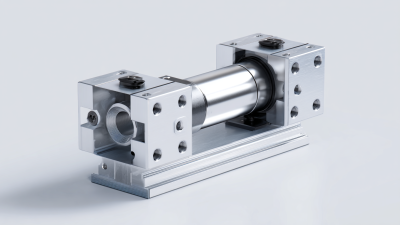

Part Fixtures are devices that hold components in place during manufacturing. They ensure consistency and accuracy in the production process. As we strive for efficiency, the design and implementation of these fixtures become vital. However, not all fixtures achieve their intended purpose, highlighting areas needing improvement.

In 2026, we face challenges related to the integration of new technologies with traditional fixtures. Striking a balance between innovation and reliability is key. Manufacturers must reflect on their fixture designs and ask whether they truly meet current demands. Only through careful analysis can we hope to enhance the performance and longevity of Part Fixtures.

In the 2026 top models, a part fixture plays a crucial role in design and functionality. A part fixture refers to a specialized device that holds, supports, or positions components during manufacturing. These fixtures ensure precision and consistency in the production process. It seems straightforward, but achieving the perfect alignment can be challenging.

Manufacturers use various materials for part fixtures, including metals and plastics. Each material has its advantages and drawbacks. For instance, metal fixtures provide durability, but they can be heavy. On the other hand, plastic fixtures are lighter but may lack strength. It’s essential to choose the right balance based on specific needs and tolerances.

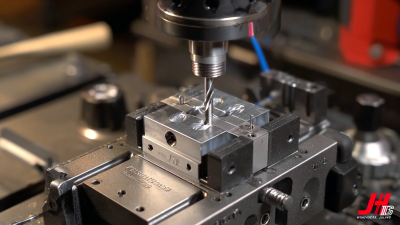

There's also a learning curve involved in creating effective part fixtures. Engineers often face challenges in designing these tools. The process requires multiple iterations and refinements. Some designs may look promising initially, but they fail during testing. This is an area ripe for improvement. A focus on collaboration between teams can enhance fixture design. Exploring innovative solutions could lead to significant advancements in efficiency and performance.

In automotive design, part fixtures play a crucial role. They provide essential support during the manufacturing process. By securing components in place, these fixtures ensure accurate alignment. This precision is vital for effective assembly.

Part fixtures also enhance efficiency. Workers can assemble parts faster when tools are reliable and consistent. However, this process is not without its flaws. Sometimes, fixtures can wear down, leading to misalignments. Reflecting on these issues helps improve future designs.

In 2026, top models will likely incorporate advanced fixtures. Improved materials and technology promise greater durability and precision. Still, the industry must address potential limitations. Continuous evaluation is necessary. Adapting and learning from challenges will ultimately push automotive design forward.

This chart illustrates the number of part fixtures used for various components in the design of top models in 2026. Each component requires a distinct set of fixtures to ensure precision and efficiency in the manufacturing process. The data indicates a higher reliance on fixtures for body assembly and interior installations.

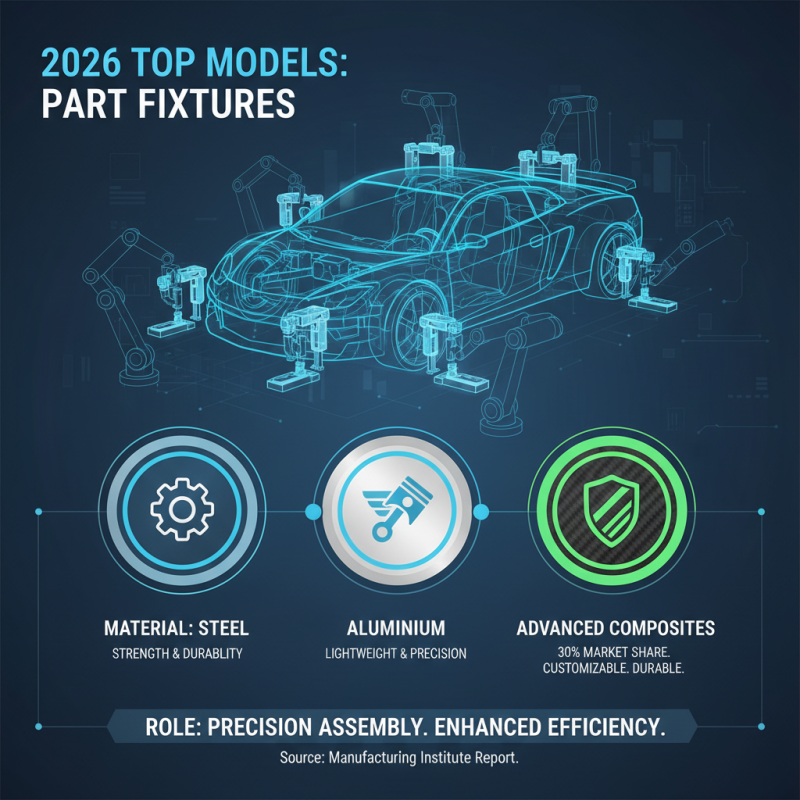

Part fixtures play an essential role in assembling top models in 2026. These fixtures are designed to hold parts in place during manufacturing or assembly. Various materials are used for part fixtures, each chosen for its specific properties. For example, steel is often favored for its strength, while aluminum is selected for its lightweight characteristics. A report by the Manufacturing Institute highlights that approximately 30% of manufacturers are now opting for advanced composites. These materials provide durability and can be tailored for unique applications.

Manufacturing techniques also evolve to enhance the efficiency of part fixtures. Techniques like 3D printing allow for rapid prototyping and customization. According to a study by Deloitte, 70% of manufacturers are utilizing additive manufacturing to create intricate designs that weren't possible before. This flexibility enables companies to adjust quickly to market demands. Despite these advancements, challenges persist. Ensuring fixture accuracy remains crucial as small deviations can impact the final product's quality. Many firms still struggle with alignment issues during assembly, prompting a need for continuous reflection on current practices.

In the evolving landscape of manufacturing, part fixtures play a crucial role in enhancing production efficiency. Industry reports indicate that well-designed part fixtures can increase productivity by up to 30%. They offer precise alignment and stability during assembly processes. This ensures that components fit together accurately, reducing the risk of errors.

However, the implementation of part fixtures is not without challenges. A study highlighted that nearly 20% of manufacturing delays stem from fixture design flaws. Issues such as improper sizing or lack of adjustability can lead to costly rework. Companies must invest time in prototyping and testing fixtures to avoid these pitfalls.

Moreover, the quality of the final product is directly influenced by the effectiveness of part fixtures. A recent survey found that 70% of manufacturers reported improved product quality after optimizing their fixtures. Yet, a significant number still overlook regular maintenance. Neglected fixtures can lead to uneven wear and inconsistent results, sparking a need for continuous evaluation and refinement in fixture design.

| Part Fixture Type | Impact on Production Efficiency (%) | Quality Improvement (%) | Common Applications |

|---|---|---|---|

| Automated Clamping Fixture | 20 | 15 | Assembly Lines |

| Manual Assembly Fixture | 10 | 8 | Consumer Electronics |

| Machining Fixture | 15 | 12 | Automotive Parts |

| Welding Fixture | 25 | 20 | Metal Fabrication |

| Inspection Fixture | 5 | 25 | Quality Control |

In 2026, the automotive industry will witness significant transformations in part fixture design. Sustainability will drive many changes. The use of lightweight materials can improve efficiency. According to industry reports, lightweight fixtures can reduce energy consumption by up to 20%. This shift emphasizes environmentally-friendly practices.

Design must focus on adaptability. Modular fixtures will allow manufacturers to easily update production lines. These systems will respond quickly to changing market demands. Data indicates that flexible fixtures can shorten lead times by nearly 30%. As the industry evolves, maintaining quality while enhancing speed will be challenging.

**Tip:** Integrate smart technologies into fixtures. Automated monitoring can ensure precision. This technology may identify issues before they become serious problems.

Collaboration between manufacturers and engineers is vital. However, miscommunication can hinder progress. Misalignment in goals may lead to inefficiencies. Reflecting on these areas can drive improvements. Engaging in open discussions may foster innovation in part fixture design.