In today's competitive manufacturing landscape, maximizing efficiency in production processes is critical, and plastic fixtures have emerged as essential tools in this pursuit. Recent industry reports indicate that the use of advanced plastic fixtures can enhance productivity by up to 30%, as they offer lightweight, durable, and customizable solutions compared to traditional materials.

According to the 2022 Plastics Industry Association report, the global demand for plastic fixtures is projected to grow steadily, driven by innovations that focus on operational efficiency and sustainability. Implementing industry standards alongside innovative practices not only streamlines production cycles but also reduces waste and costs, fostering a more sustainable manufacturing environment.

Therefore, understanding how to effectively integrate plastic fixtures into production lines is paramount for manufacturers aiming to stay ahead in an increasingly demanding market.

In today's competitive manufacturing landscape, maximizing efficiency in production processes is critical, and plastic fixtures have emerged as essential tools in this pursuit. Recent industry reports indicate that the use of advanced plastic fixtures can enhance productivity by up to 30%, as they offer lightweight, durable, and customizable solutions compared to traditional materials.

According to the 2022 Plastics Industry Association report, the global demand for plastic fixtures is projected to grow steadily, driven by innovations that focus on operational efficiency and sustainability. Implementing industry standards alongside innovative practices not only streamlines production cycles but also reduces waste and costs, fostering a more sustainable manufacturing environment.

Therefore, understanding how to effectively integrate plastic fixtures into production lines is paramount for manufacturers aiming to stay ahead in an increasingly demanding market.

Implementing industry standards in plastic fixture production is essential for maximizing efficiency and ensuring product quality. According to a report by the American Society for Quality, organizations that adopt standardized production processes can see a productivity increase of up to 20%. This boost is largely attributed to reduced variability in manufacturing, which allows teams to focus on continuous improvement and innovation.

Tips: Establish a culture that prioritizes compliance with industry standards. Conduct regular training sessions for your team to familiarize them with the latest standards and innovations. This not only aids in streamlining production but also enhances employee engagement and accountability.

In addition, leveraging advanced technologies such as automation and data analytics can significantly optimize production processes. A study from the Plastic Industry Association found that companies incorporating automation in their workflows achieved a 30% reduction in lead times. By analyzing production data, manufacturers can identify bottlenecks and implement strategies that align with established benchmarks.

Tips: Invest in modern machinery that supports quick adjustments to production parameters, allowing for real-time responses to changing demands. Regularly review performance metrics to ensure alignment with industry standards and to facilitate continuous improvement efforts.

In today’s fast-paced manufacturing environment, the integration of innovative materials in production processes is essential for enhancing efficiency and ensuring longevity. According to a report by MarketsandMarkets, the global advanced materials market is projected to grow from $18.0 billion in 2021 to $27.2 billion by 2026, highlighting the increasing demand for materials that contribute to superior production outcomes. By utilizing advanced plastics and composites, manufacturers can achieve significant reductions in weight, increased durability, and improved overall performance.

Tips: Consider integrating materials such as high-performance thermoplastics, which offer exceptional heat resistance and reduced wear over time. This not only boosts production throughput but also minimizes maintenance costs, ultimately extending the lifecycle of fixtures and molds.

Furthermore, implementing innovative designs alongside these materials can amplify their benefits. A recent study from the National Institute of Standards and Technology (NIST) found that optimized fixture design can lead to a 30% increase in production efficiency. By adhering to industry standards and leveraging modern materials and technologies, manufacturers can effectively enhance both productivity and product quality.

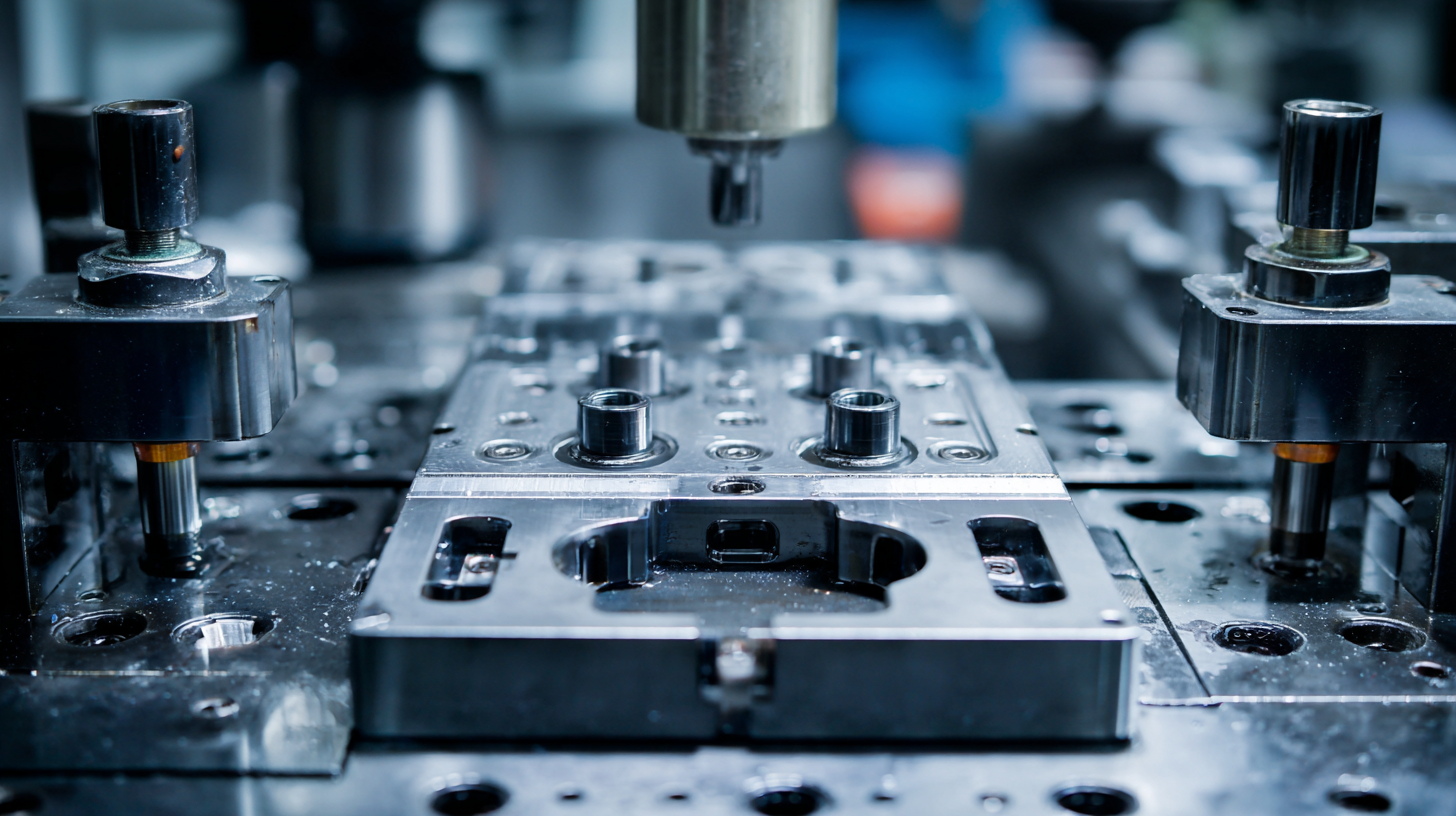

Benchmarking production processes against industry best practices is essential for maximizing efficiency when using plastic fixtures. This involves evaluating current manufacturing methodologies, material selection, and handling techniques against the standards set by leading industry players. By identifying gaps between existing processes and best practices, manufacturers can adopt strategies that enhance productivity, reduce waste, and lower costs.

Additionally, leveraging innovations in technology plays a crucial role in refining production processes. The integration of automated systems, advanced material compositions, and state-of-the-art design software can streamline operations. For instance, employing 3D printing for prototyping plastic fixtures promotes rapid iteration and reduces lead times. Continuous monitoring and improvement based on industry benchmarks not only improve efficiency but also ensure compliance with regulatory standards. By embracing these practices, manufacturers can position themselves competitively while fostering a culture of continuous improvement.

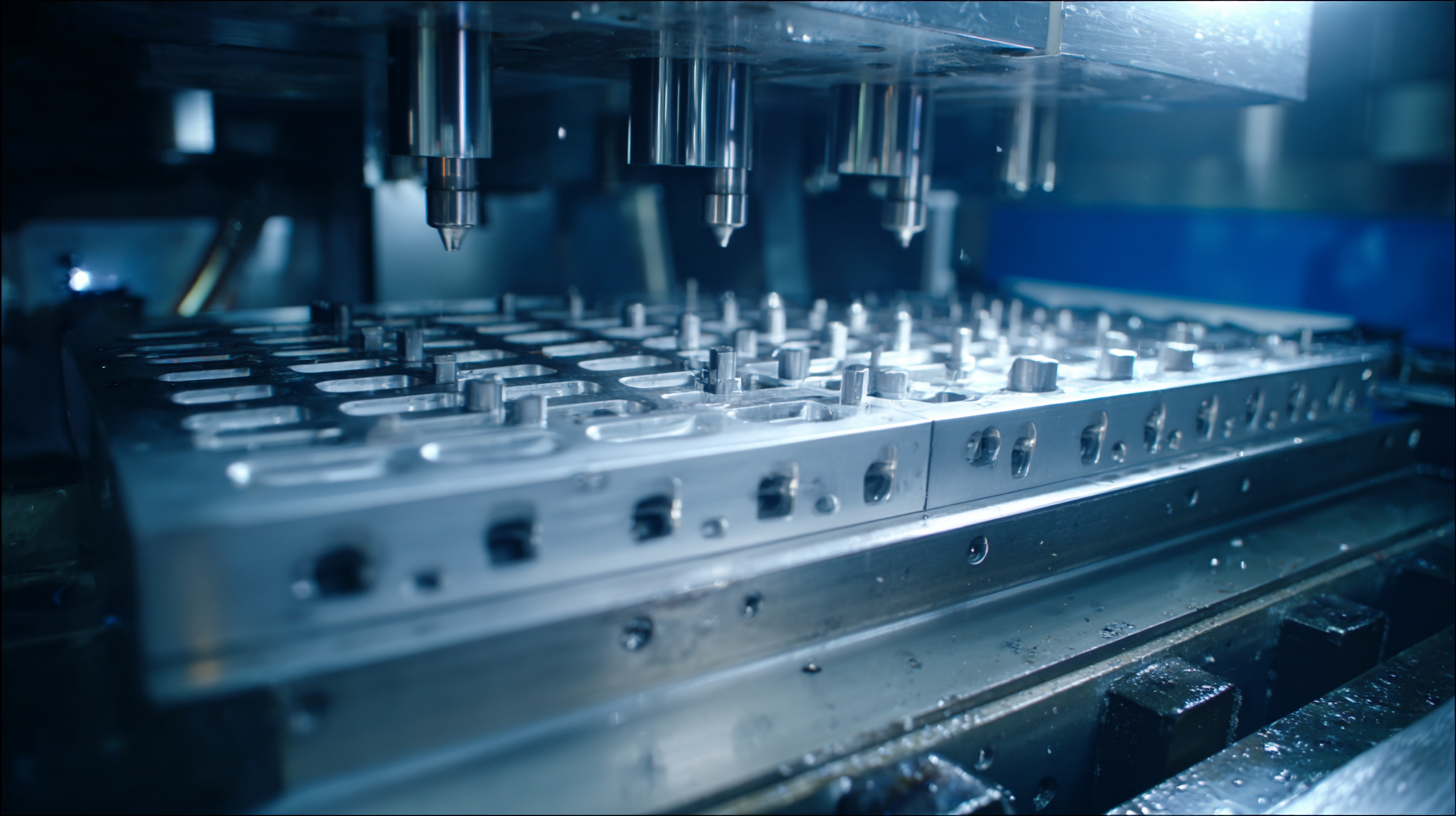

Integrating automation and smart technology into plastic fixture manufacturing is pivotal for maximizing production efficiency. Modern manufacturing systems are increasingly adopting robotic automation, which speeds up the production process and reduces human error. Automated systems can perform repetitive tasks with precision, enabling manufacturers to meet high demand without compromising quality.

Furthermore, smart technology such as IoT (Internet of Things) can facilitate real-time monitoring, allowing operators to track machines and processes, resulting in timely adjustments and maintenance.

Moreover, the implementation of advanced data analytics and artificial intelligence can enhance decision-making throughout the production cycle. By analyzing production data, manufacturers can identify bottlenecks and inefficiencies, paving the way for continuous improvement. Predictive analytics can also forecast equipment failures, ensuring proactive maintenance and reducing downtime.

Ultimately, by leveraging these innovations, plastic fixture manufacturers can achieve a more agile and responsive production environment, leading to enhanced productivity and cost savings.

In recent years, the manufacturing industry has witnessed significant advancements in plastic fixture innovations, greatly enhancing production efficiency. Case studies reveal that companies adopting modern plastic fixtures have reported a 20-30% reduction in production time. For instance, a notable case involves a leading automotive manufacturer that integrated lightweight plastic fixtures in its assembly line, resulting in improved handling and a decrease in cycle time. This innovation not only streamlined operations but also lowered material costs, showcasing how strategic changes can lead to substantial gains.

Tip: Consider conducting a thorough analysis of your existing fixtures. Identify areas where lighter and more versatile plastics could replace metal fixtures, potentially improving speed without sacrificing durability.

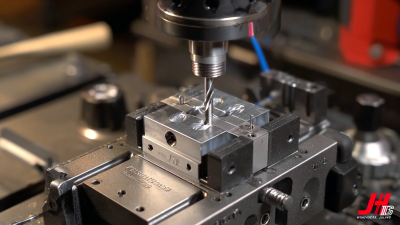

Another case study highlights a consumer electronics company that implemented 3D-printed plastic fixtures. This move allowed for rapid prototyping and customization, significantly reducing lead times by up to 40%. The flexibility of additive manufacturing enabled them to produce complex geometries that traditional methods couldn't achieve, underscoring the importance of embracing innovative materials and technologies.

Tip: Stay updated with industry standards and innovations by attending trade shows and webinars. Networking with experts can provide insights into cutting-edge plastic fixture technologies that could revolutionize your production process.