In today's competitive manufacturing landscape, the pursuit of precision and quality is paramount, making the Comprehensive Checking Fixture an invaluable tool for ensuring error-free production processes. This guide aims to demystify the implementation of Comprehensive Checking Fixtures through a structured, step-by-step approach that empowers manufacturers to enhance their quality control measures. By leveraging a well-designed checklist, teams can systematically assess all aspects of their checking fixtures, from initial setup and calibration to ongoing maintenance and evaluation. This blog will walk you through the essential elements that make a Comprehensive Checking Fixture effective, ensuring that every component of your manufacturing process aligns with rigorous industry standards and customer expectations.

Join us as we unlock the potential of Comprehensive Checking Fixtures and elevate your quality assurance practices to new heights.

In today's competitive manufacturing landscape, the pursuit of precision and quality is paramount, making the Comprehensive Checking Fixture an invaluable tool for ensuring error-free production processes. This guide aims to demystify the implementation of Comprehensive Checking Fixtures through a structured, step-by-step approach that empowers manufacturers to enhance their quality control measures. By leveraging a well-designed checklist, teams can systematically assess all aspects of their checking fixtures, from initial setup and calibration to ongoing maintenance and evaluation. This blog will walk you through the essential elements that make a Comprehensive Checking Fixture effective, ensuring that every component of your manufacturing process aligns with rigorous industry standards and customer expectations.

Join us as we unlock the potential of Comprehensive Checking Fixtures and elevate your quality assurance practices to new heights.

In the manufacturing sector, the importance of comprehensive checking fixtures cannot be underestimated. These tools serve as critical components in the production process, ensuring that products meet specified dimensions and tolerances. The integration of comprehensive checking fixtures into manufacturing workflows enhances quality control by enabling consistent measurement and inspection of parts throughout the production line. By employing these fixtures, manufacturers can reduce the risk of defects, improve product reliability, and ultimately save costs associated with rework and scrap.

Moreover, comprehensive checking fixtures facilitate a smoother transition from design to production. They allow for quick validation of prototypes and assembly processes, ensuring that any issues are identified early in the manufacturing cycle. This proactive approach not only leads to a more efficient production process but also enhances collaboration between design and engineering teams. By recognizing and implementing comprehensive checking fixtures, organizations can achieve higher levels of precision and efficiency in their manufacturing operations, which is essential in today’s competitive landscape.

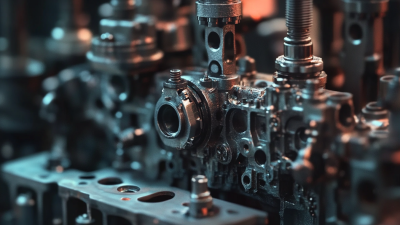

When it comes to the effective implementation of checking fixtures, understanding the key components is essential. The choice of materials plays a significant role in the durability and accuracy of the fixture. For instance, using lightweight yet robust materials such as aluminum or high-strength plastics can enhance portability while maintaining structural integrity. Additionally, the selection of materials must consider the specific application—corrosive environments may require stainless steel or specially coated surfaces to prevent degradation over time.

Design elements are equally crucial in creating functional checking fixtures. Ensuring ergonomic designs that facilitate easy access to measurement points can streamline the checking process and minimize errors. Incorporating adjustable components can adapt to various parts, making the fixture versatile across different products. Precision in design also means incorporating features such as locating pins and clamps that secure the workpiece effectively, ensuring accurate measurements. By focusing on these materials and design aspects, manufacturers can drastically improve the efficiency and reliability of their checking fixtures.

| Component | Material | Design Element | Importance |

|---|---|---|---|

| Base Plate | Aluminum | Flat and Rigid | Provides stability |

| Locators | Steel | Precision-fit Design | Ensures part alignment |

| Clamping System | Polymer | Ergonomic Design | Secures components |

| Sensors | Electronics | Integrated System | Monitors quality |

| Adjustment Mechanism | Brass | Threaded Design | Allows fine-tuning |

When implementing comprehensive checking fixtures, taking a data-driven approach can significantly enhance efficiency gains. By systematically gathering and analyzing performance data, teams can identify bottlenecks in the environment and adapt their strategies accordingly. This enables organizations to make informed decisions based on real performance metrics rather than assumptions.

Tip: When collecting data, focus on key performance indicators (KPIs) such as cycle time, error rates, and rework frequency. This will provide a clearer picture of how the new fixtures are impacting your workflow.

Moreover, involving team members in the analysis process can uncover insights that may be overlooked. Cross-functional workshops can facilitate knowledge sharing and lead to innovative solutions tailored to specific challenges. By leveraging diverse perspectives, teams can optimize fixture design and deployment strategies to maximize their effectiveness.

Tip: Regularly review your data with the team to foster a culture of continuous improvement. Consider setting up monthly check-ins to discuss findings and collaboratively brainstorm areas for enhancement.

In today's competitive manufacturing landscape, developing custom checking fixtures is vital for ensuring high-quality outputs and operational efficiency. According to a report by the International Society of Automation, integrating checking fixtures can reduce inspection times by up to 30%, significantly speeding up the overall production process. Custom fixtures allow manufacturers to streamline workflows, minimize human error, and enhance accuracy during the quality control phases of production.

To effectively implement these fixtures, it is essential to follow a systematic approach. Begin by thoroughly analyzing your production line needs, focusing on the specific tolerances and dimensions required for your products. A study from the Precision Engineering Institute indicates that custom checking fixtures can increase productivity by 15% when adapted to meet the unique specifications of each production run. Engaging with engineers and technicians in the design process ensures that the fixtures not only meet regulatory standards but also improve the ease of use for operators, ultimately leading to a more robust production line.

When designing checking fixtures, one prevalent pitfall is inadequate consideration of tolerance stacks, which can lead to significant production errors. According to a study by the National Institute of Standards and Technology (NIST), improper tolerance management can result in up to 15% of manufacturing defects due to unaddressed variance. Therefore, it’s crucial to accurately assess the cumulative tolerances of all components in the fixture design to ensure that parts are checked against the intended specifications without excessive play or misalignment.

Another common mistake is neglecting the user-friendliness of the fixtures. A report from the Society of Manufacturing Engineers (SME) indicates that approximately 20% of testing delays can be attributed to complicated fixture setups that require excessive training for operators. Investing time in creating intuitive designs not only streamlines the inspection process but also significantly cuts down on human error. Incorporating features that allow for easier part loading and unloading can facilitate better fixture ergonomics and enhance overall productivity in the production line. By focusing on these aspects, manufacturers can mitigate common pitfalls and boost the effectiveness of their checking fixture implementation.