In the rapidly evolving landscape of manufacturing, the efficiency and precision of production processes are paramount to success. Fixtures jigs play a crucial role in achieving these objectives, as they are essential tools that enhance accuracy and reduce production time. According to a report by the American Society for Quality, implementing quality fixtures and jigs can improve production efficiency by up to 30%, underscoring their importance in both assembly lines and machining operations. As industries face increasing competition and evolving technological demands, understanding the key features of the best fixtures jigs becomes essential for manufacturers looking to optimize their processes. This blog will outline five essential features of fixtures jigs that you cannot afford to overlook, ensuring you stay at the forefront of manufacturing excellence.

When selecting fixtures and jigs for manufacturing processes, assessing their durability is paramount. The global tooling market, projected to grow significantly by 2033, highlights the increasing importance of high-performance solutions like jigs and fixtures, which account for a substantial share of market dynamics. Analyzing essential durability metrics can ensure that the chosen tools not only meet the demands of production but also withstand the rigors of continuous use.

To enhance the longevity of fixtures and jigs, manufacturers should consider factors such as material composition, resistance to wear and tear, and environmental adaptability. For instance, high-grade materials contribute to increased resistance against deformation, ensuring that even under high-stress situations, the tools maintain their integrity.

**Tip:** Regular maintenance is crucial. Implementing a systematic inspection routine can preemptively identify issues, ultimately prolonging the life of your fixtures and jigs.

Another vital consideration is the adaptability of fixtures to different manufacturing processes. As the tooling market evolves, integrating innovative designs that accommodate various components can not only improve workflow efficiency but also reduce downtime.

**Tip:** Investing in modular fixtures can allow for quicker adjustments and configurations, leading to increased flexibility in production lines.

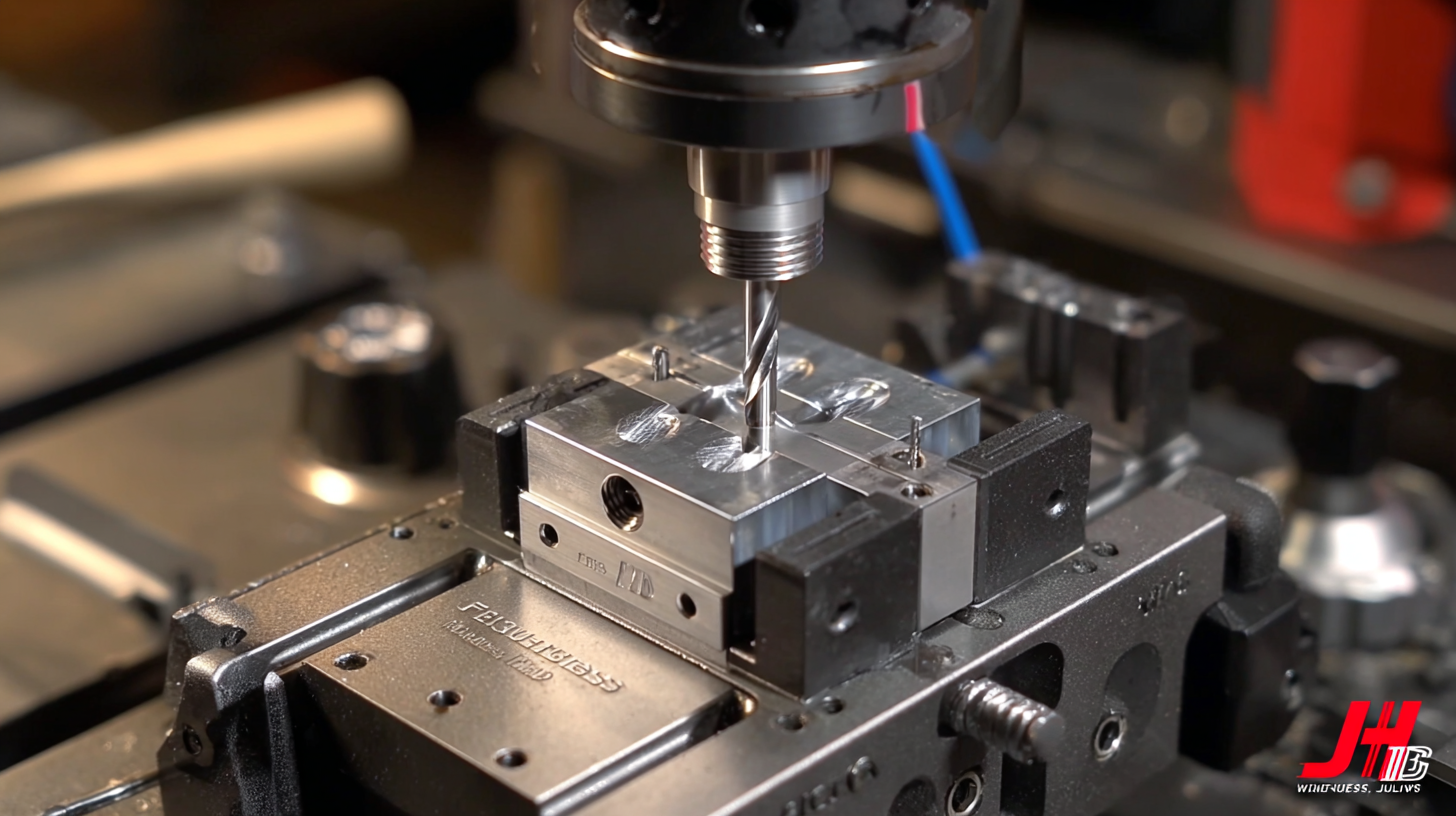

Precision engineering plays a pivotal role in the effectiveness of fixture jigs, particularly with respect to tolerance levels. In manufacturing processes, the tolerance levels dictate how closely parts fit together, which can directly affect the overall quality and performance of the final product. A study has shown that variations in tolerance can lead to a 15% decrease in product efficiency, emphasizing the importance of maintaining strict standards. This is especially critical when using jigs for precision tasks, where even minor deviations can result in significant errors in production.

To optimize the effectiveness of fixture jigs, it's essential to invest in high-quality materials and precision measurement tools. Tips for achieving this include regularly calibrating measurement instruments to ensure accuracy and utilizing software that allows for precise modeling of tolerance levels. Additionally, employing advanced manufacturing techniques, such as 3D printing, can enhance the adaptability and precision of jigs, allowing them to cater to different parts without compromising quality.

Moreover, the incorporation of carefully designed lighting in production environments has been shown to improve accuracy in tasks that rely on precision. An energy-efficient LED setup, properly balanced for the specific needs of the workspace, can enhance visibility and reduce eye strain, fostering better performance. Therefore, when designing or selecting fixture jigs, consider not only the mechanical aspects but also the environmental factors that contribute to precision engineering.

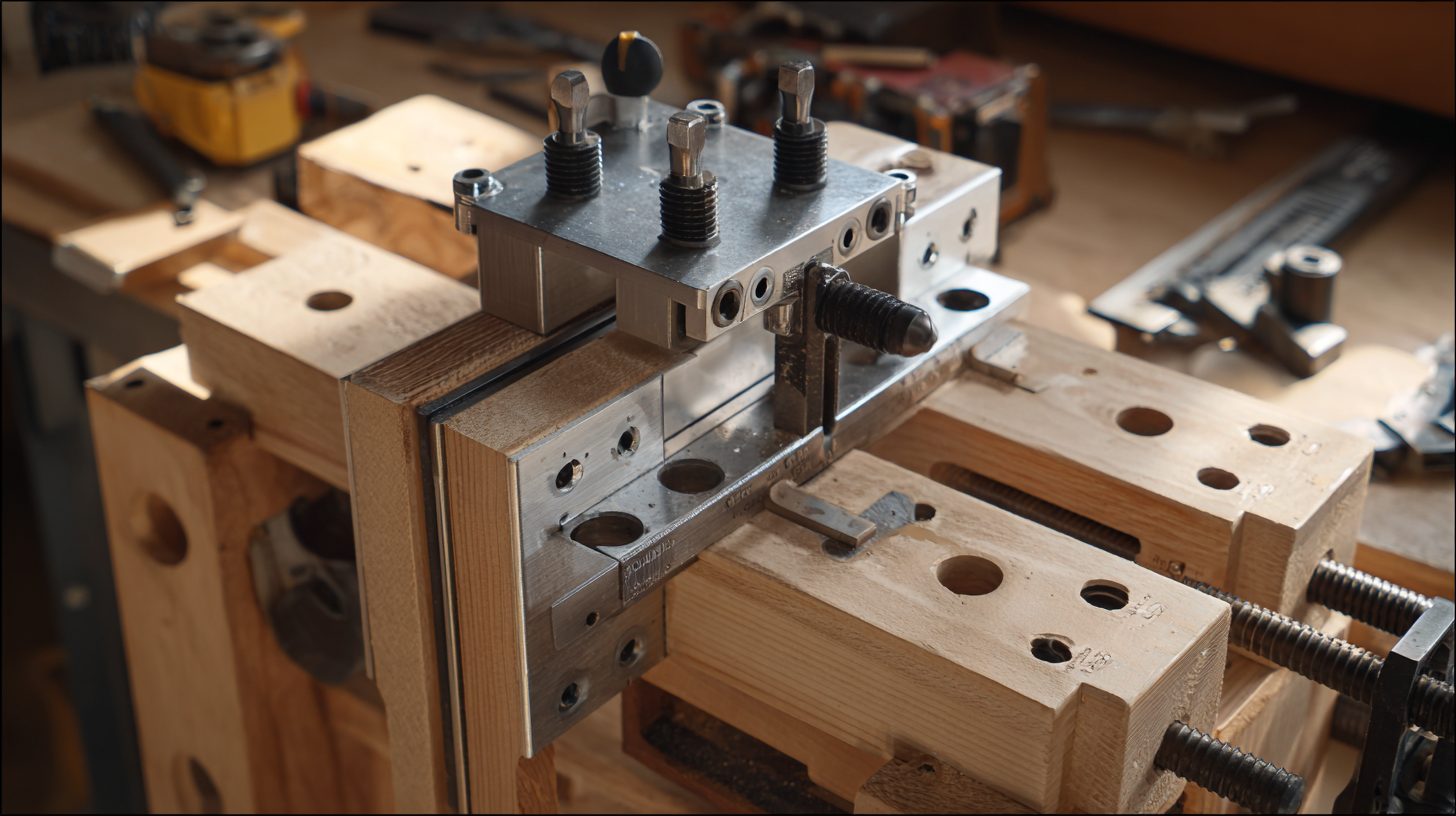

When it comes to choosing the best fixtures and jigs, understanding the key material properties of steel and aluminum is crucial. Steel is renowned for its strength and durability, making it an ideal choice for heavy-duty fixtures that require long-lasting performance. However, its weight can be a disadvantage in applications where mobility and ease of handling are essential. On the other hand, aluminum offers a lightweight alternative while providing adequate strength for various tasks. It is especially beneficial in applications that require frequent repositioning or adjustments, making it a favorite among hobbyists and professionals alike.

Tip: When selecting materials for your fixtures, consider the specific demands of your project. If you're dealing with high-stress environments, steel may be the way to go. But for lighter applications where reduced weight is paramount, aluminum can enhance productivity without sacrificing performance.

Another factor to weigh is corrosion resistance. Steel fixtures may require additional treatments or coatings to resist rust, particularly in humid environments. In contrast, aluminum naturally resists corrosion, which can prolong the life of your fixtures without the need for extensive maintenance.

Tip: Always assess the operating conditions of your fixtures. If your workspace is prone to moisture, investing in aluminum could save you time and money in the long run.

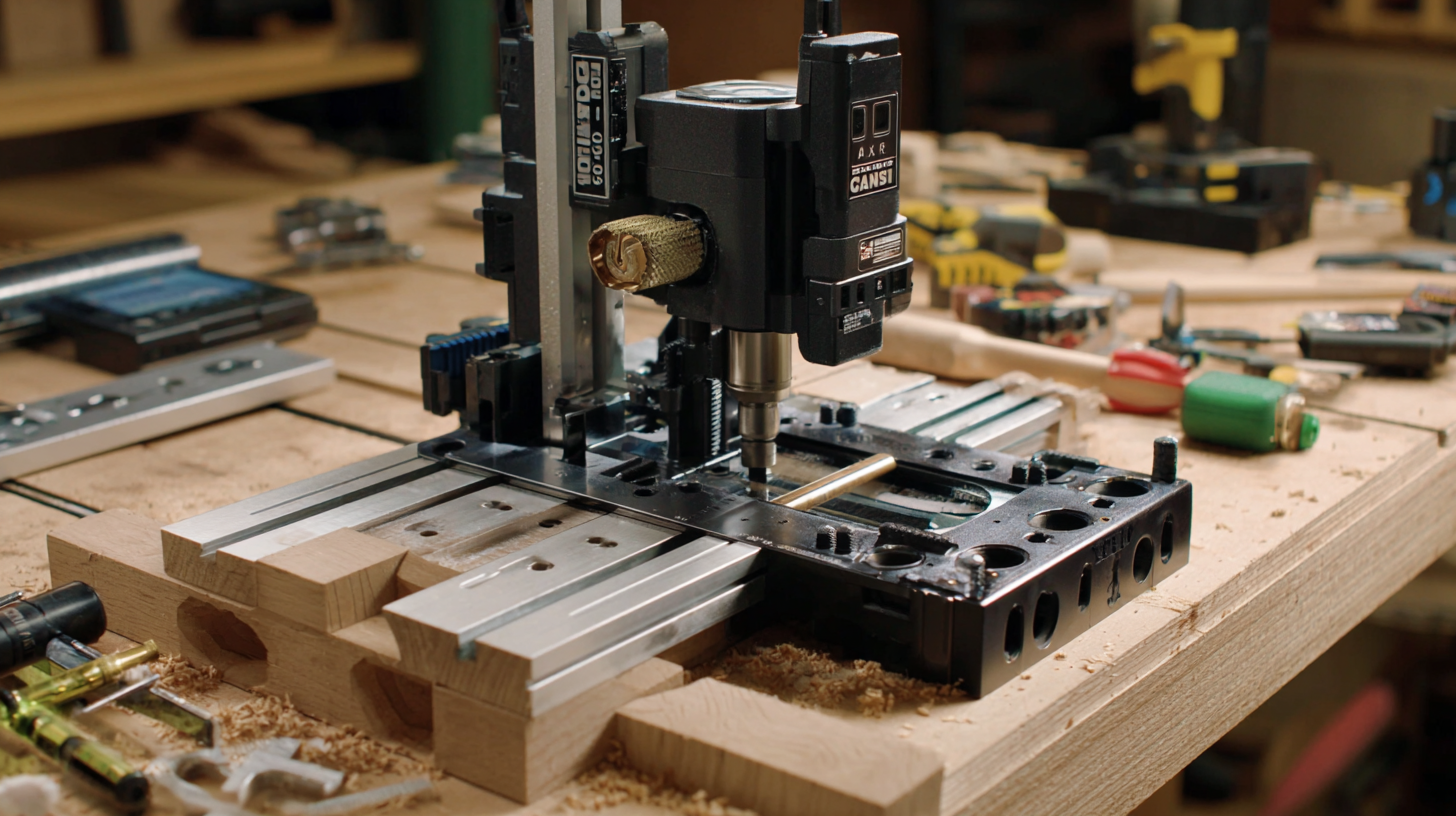

In the world of fixtures jigs, innovative design features are paramount in enhancing both versatility and productivity. A well-designed jig not only streamlines the workflow but also adapts to various tasks, making it an indispensable tool for any workshop. Key attributes such as adjustable components, modular designs, and user-friendly interfaces can significantly elevate the performance of any jig.

When selecting the best fixtures jigs, consider incorporating features that promote efficiency. For instance, jigs with integrated measurement systems eliminate guesswork and save valuable time. Additionally, those that support quick tool changes can greatly increase productivity, allowing users to switch tasks seamlessly without losing momentum.

Another crucial tip is to look for jigs that offer compatibility with various materials. Versatile jigs that can handle everything from wood to metal provide the flexibility needed for diverse projects. Opt for designs that allow for easy customization, enabling you to tackle unique challenges and expand your capabilities effectively.

In the fast-paced world of manufacturing, efficiency is key to staying competitive.

Optimal fixture jigs play a pivotal role in streamlining production processes, with studies indicating they can reduce production time by up to 30%.

According to a report by the National Institute of Standards and Technology (NIST), well-designed jigs minimize setup times and reduce waste, contributing to significant cost savings and higher output rates.

By investing in quality fixture jigs, companies can enhance their operational efficiency and maintain a leading edge in their industry.

When selecting fixture jigs, consider the following tips to maximize efficiency:

First, ensure that your jigs are customizable to accommodate different tasks—this versatility can greatly improve adaptability on the production floor.

Second, prioritize jigs made from durable materials; this not only extends their lifespan but also maintains precision over time, leading to consistent production quality.

Finally, regular maintenance is vital; a well-maintained jig can outperform even the most advanced jigs long-term, saving both time and resources.

Implementing these features and considerations can lead to a more efficient production process, reinforcing the importance of selecting the right fixtures jigs in today's competitive manufacturing landscape.