In the rapidly evolving manufacturing landscape, the importance of selecting the appropriate Aluminium Parts cannot be overstated. Recent industry reports indicate that the global aluminium market is projected to reach approximately $250 billion by 2025, with the demand for lightweight and durable materials on the rise. Aluminium Parts are gaining prominence due to their excellent strength-to-weight ratio and resistance to corrosion, making them ideal for various applications, from automotive to aerospace. However, choosing the right aluminium components can be a complex task, as it involves understanding specific requirements such as alloy types, finishing processes, and production techniques. This blog aims to guide manufacturers in navigating this critical decision-making process to ensure optimal performance and cost-effectiveness in their products.

When it comes to manufacturing, selecting the appropriate aluminium alloy is crucial for achieving the desired strength, weight, and corrosion resistance. The primary groups of aluminium alloys are classified into two categories: wrought and cast. Wrought alloys, such as the 6000 series, are versatile and commonly used for structural applications due to their excellent machinability and strength. On the other hand, cast alloys, like the 300 series, can withstand higher stress loads and are typically used in specialized applications like automotive parts and aerospace components.

Understanding the unique properties of each aluminium alloy is essential for optimizing performance. For instance, 2024 aluminium, which is known for its high strength-to-weight ratio, is often employed in aerospace due to its lightweight nature and superior fatigue resistance. Conversely, 7075 aluminium is favored in applications requiring high strength, such as military and sporting equipment. Evaluating the specific requirements of your manufacturing process will help ensure that the chosen aluminium parts meet both performance and durability standards.

When selecting aluminium parts for manufacturing, several critical factors should guide your decision-making process. Firstly, understanding the specific requirements of your application is paramount. For instance, the strength-to-weight ratio, corrosion resistance, and thermal conductivity of aluminium can vary greatly depending on the alloy chosen. According to the Aluminium Association, over 90% of aluminium materials in industries are specific to certain properties, hence identifying whether you need alloy 6061 for structural components or alloy 2024 for aerospace applications can significantly influence performance and durability.

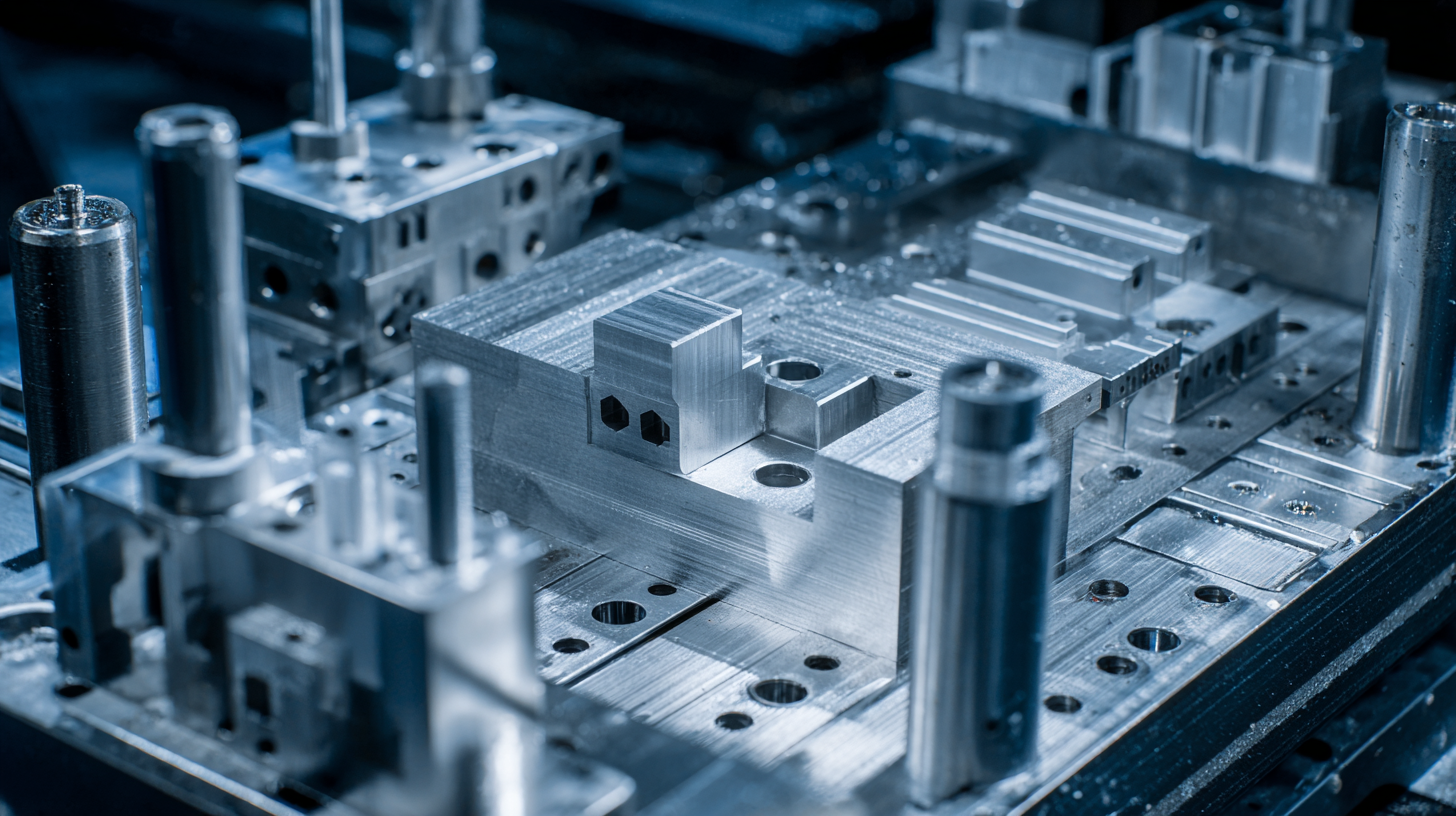

Secondly, consider the manufacturing processes involved. Different techniques, such as extrusion, die casting, or machining, may necessitate specific grades of aluminium to achieve the desired precision and finish. Recent reports from TechNavio indicate that the global aluminium extrusion market is projected to grow by 5% annually through 2025, highlighting the increasing demand for tailored aluminium solutions. In this context, exploring supplier capabilities and their ability to meet your production volume and customization requirements is crucial for ensuring a seamless manufacturing process.

When it comes to manufacturing processes, the advantages of using aluminum parts cannot be overstated. Aluminum's lightweight properties significantly contribute to reducing the overall weight of products, which is particularly critical in industries such as aerospace and automotive. This weight reduction not only enhances performance and fuel efficiency but also aids in achieving sustainability goals. Recent trends in additive manufacturing highlight how aluminum parts are being increasingly used to create intricate designs that were previously difficult to manufacture with traditional methods.

Tips for choosing the right aluminum parts include evaluating the specific requirements of your project, such as weight constraints, strength, and corrosion resistance. Understanding the latest developments in aluminum 3D printing can provide you with insights into the technologies and processes available, ensuring that you select parts that meet your manufacturing needs effectively.

Moreover, consider the impact of advances in metal additive manufacturing. By leveraging modern technologies, manufacturers can achieve greater flexibility and scalability in production, resulting in the ability to produce high-quality aluminum parts with intricate geometries. This can lead to further improvements in efficiency and overall product performance, making aluminum an even more attractive choice for manufacturers aiming to stay competitive in today's market.

When it comes to manufacturing, cost-effectiveness is a crucial consideration, and aluminium parts often stand out as a preferred choice. One of the primary reasons for this is the balance they offer between affordability and performance. Aluminium is lighter than steel, which not only reduces transportation costs but also enhances the efficiency of the end product. Moreover, aluminium’s excellent resistance to corrosion means that parts require less frequent replacements, further decreasing long-term operational expenses.

Additionally, the versatility of aluminium in manufacturing processes such as extrusion and casting can lead to significant savings. These processes allow designers to create complex shapes without the need for extensive machining, minimizing production time and waste. It's important to evaluate the specific requirements of your project, such as weight considerations or environmental factors, as these can influence the overall cost-effectiveness. By carefully assessing these aspects, manufacturers can make informed decisions about incorporating aluminium parts into their operations, ultimately driving both efficiency and profitability.

Aluminium components are increasingly preferred across various industries due to their versatile applications, coupled with advancements in technology and a commitment to sustainability. In sectors like automotive, aerospace, and renewable energy, aluminium's lightweight nature and strength make it an ideal choice for manufacturing components that meet stringent performance criteria, while also contributing to energy efficiency. The automotive composites market, for instance, is projected to reach $1.35 billion by 2026, driven by the need for materials that enhance fuel efficiency and reduce overall weight.

Moreover, the push towards sustainable and green manufacturing practices is a significant factor driving the growth of the aluminium market. With the global aluminium market expected to surpass $245 billion by 2024, industries are increasingly recognizing the importance of using recycled aluminium and developing eco-friendly production methods. The photovoltaic sector also highlights the debate between aluminium and alternative materials for solar panel frames, showcasing aluminium’s longstanding position in the market due to its durability and recyclability.

As technology evolves and market demands shift, the strategic selection of aluminium parts will be pivotal in fostering innovation while adhering to sustainability goals in manufacturing.