In the evolving landscape of aerospace manufacturing, selecting the right Aerospace Fixtures is crucial for achieving efficiency and precision in production processes. According to Dr. Emily Carter, a leading expert in aerospace engineering, "The quality and design of Aerospace Fixtures can significantly impact the overall success of any aerospace project." With the increasing complexity and technological advancements in the aerospace sector, the demand for specialized fixtures that cater to specific operational needs has never been higher.

Choosing the appropriate Aerospace Fixtures involves various considerations, including material strength, design compatibility, and the ability to withstand rigorous operational environments. As the industry pushes towards more innovative designs and sustainable practices, engineers must ensure that the fixtures they select not only align with current project requirements but also anticipate future advancements. This critical decision-making process can greatly influence production timelines, cost efficiency, and ultimately, the safety and reliability of aerospace components.

As projects become more specialized, the dialogue around Aerospace Fixtures continues to grow, emphasizing the need for tailored solutions that address unique challenges. Understanding the intricacies of this selection process is essential for both seasoned professionals and newcomers aiming to make a mark in the aerospace industry.

Aerospace fixtures play a pivotal role in the precision and efficiency of manufacturing processes in the aerospace industry. These custom-made tools are designed to hold and support components during fabrication, assembly, and inspection. Their primary importance lies in ensuring that parts remain securely in place, minimizing the risk of errors and enhancing overall product integrity. High-quality fixtures contribute significantly to the accuracy of measurements and can help streamline workflows, which is critical in an industry where tolerances are exceptionally tight.

Furthermore, the choice of aerospace fixtures can impact not only the quality of the final product but also operational efficiency. Selecting the right fixtures involves understanding the specific requirements of the projects at hand, including the materials involved, the complexity of the components, and the intended manufacturing processes. Well-designed fixtures can reduce setup time, improve repeatability, and facilitate easier access for inspection and maintenance. When projects demand advanced technologies or intricate designs, the right aerospace fixtures can be the difference between a successful outcome and potential setbacks in production.

This chart displays the percentage distribution of various aerospace fixtures used in projects based on their material type and application. Understanding these distributions can aid in making informed decisions for future needs.

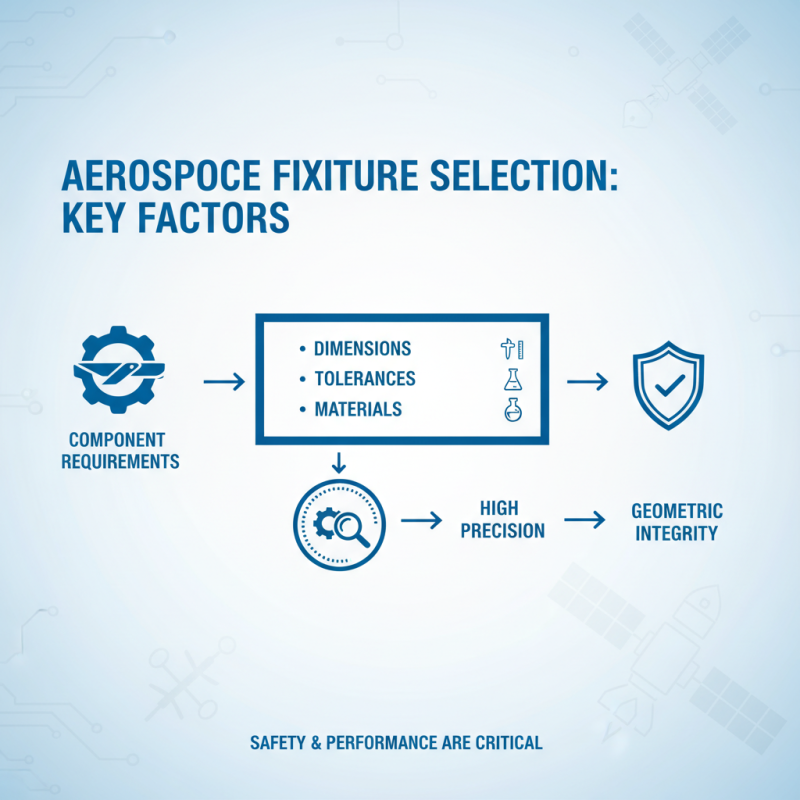

When selecting aerospace fixtures for your projects, one of the most critical factors to consider is the specific requirements of the components you will be working with. This includes understanding the dimensions, tolerances, and materials of the items being held or processed. High precision is required in aerospace applications, where even the slightest deviation can lead to significant safety and performance issues. Therefore, evaluating the fixture’s ability to maintain geometric integrity during manufacturing and assembly processes is essential.

Another important consideration is the type of processes the fixtures will support, such as machining, assembly, or inspection. Each process may have different fixture needs, such as rigidity for machining or flexibility for assembly tasks. Ensuring that fixtures can accommodate various operational requirements will enhance productivity and reduce the likelihood of rework. Additionally, factors such as weight, ease of handling, and compatibility with existing machinery should also influence your decision. Selecting the right aerospace fixtures can lead to improved workflow efficiency and higher quality output, ultimately contributing to the success of your aerospace projects.

When it comes to aerospace fixtures, understanding the various types and their specific applications is crucial for optimizing manufacturing processes. One of the primary categories of aerospace fixtures is assembly fixtures. These are designed to hold components in place during the assembly process, ensuring accuracy and precision. Assembly fixtures can accommodate complex geometries, allowing them to support a wide range of aerospace components, from fuselage sections to engine parts. Their ability to provide repeatable positioning directly impacts the overall quality and performance of the final assembled product.

Another significant category is inspection fixtures. These fixtures are utilized to verify the dimensional accuracy of aerospace components against design specifications. They play a critical role in quality control processes, allowing engineers to conduct precise measurements using various gauges and tools. Inspection fixtures are often tailor-made to fit specific components, ensuring that every angle and contour can be accurately checked, which is vital for maintaining the stringent safety standards of the aerospace industry. Additionally, there are also tooling fixtures, which facilitate processes such as machining and welding. These fixtures support the workpieces securely during fabrication, helping to reduce cycle times and improve efficiency in production. Understanding the different types and their appropriate applications can greatly aid aerospace engineers in selecting the right fixtures for their projects, ultimately enhancing the quality and reliability of aerospace products.

| Fixture Type | Application | Material | Advantages |

|---|---|---|---|

| Assembly Fixtures | Used in the assembly of aircraft components | Aluminum | Lightweight and durable |

| Inspection Fixtures | Used for quality control inspections | Steel | High stability and precision |

| Welding Fixtures | Used during welding processes | Mild Steel | Cost-effective and strong |

| Machining Fixtures | Used in precision machining operations | Aluminum or Composite Materials | Enhanced accuracy and reduced cycle time |

| Transport Fixtures | Used for safe transport of components | Composite Materials | Lightweight and protective |

When evaluating material options for aerospace fixtures, several key factors dictate the suitability of each material based on specific project requirements. Aerospace fixtures are critical for supporting components during various manufacturing processes, including assembly, machining, and inspection. The materials used must exhibit exceptional strength-to-weight ratios, corrosion resistance, and thermal stability to withstand the rigors of aerospace applications. According to a report by the Aerospace Industries Association, lightweight materials can significantly enhance efficiency, leading to fuel savings of up to 20% in aircraft designs.

Aluminum alloys, for instance, are widely used due to their lightweight properties and ability to resist atmospheric corrosion. However, advanced composites and titanium alloys are increasingly gaining traction due to their superior strength and reduced weight, particularly in high-performance applications. A study from the International Journal of Aerospace Manufacturing highlighted that titanium fixtures can withstand extreme temperatures and stresses, making them ideal for engines and critical structural components. Selecting the right material not only optimizes the fixture's performance but also plays a crucial role in the overall sustainability of aerospace projects by minimizing waste and energy consumption during production.

When implementing aerospace fixtures in projects, adhering to best practices is crucial for ensuring precision and safety. According to a report by the Aerospace Industries Association, about 80% of failures in aerospace projects are linked to improper tooling processes. Therefore, selecting fixtures that provide high accuracy and repeatability should be the foremost priority. Designers need to evaluate the specific requirements of each project, considering factors such as material type, weight, and expected operational conditions. Incorporating advanced materials, such as carbon fiber or lightweight alloys, can enhance the performance of fixtures and reduce the overall weight of the assembly, leading to improved fuel efficiency and performance.

Another essential practice involves thorough testing and validation of fixtures before their deployment in production. A survey conducted by Boeing highlights that businesses that implement rigorous validation protocols reduce rework by approximately 25%. This step ensures that fixtures can withstand the rigorous demands of aerospace manufacturing and assembly processes, minimizing the risk of errors and ensuring the final product meets all regulatory standards. Additionally, continuous training for team members on the latest fixture technologies and techniques fosters a culture of safety and efficiency, ultimately contributing to the success of aerospace projects and enhancing the competitive edge of the organization.