Choosing the right engineering fixtures for your projects is a crucial step that can significantly influence the efficiency, accuracy, and outcome of your engineering endeavors. According to Dr. Emily Carter, a leading expert in the field of manufacturing engineering, "The success of any project hinges not just on the design but also on the tools—and engineering fixtures are paramount in ensuring that designs are translated into reality with precision." This underscores the importance of understanding the various types of fixtures available and their applications within different engineering contexts.

As projects vary in complexity and specifications, selecting the appropriate engineering fixtures becomes essential to meet unique project requirements. Engineers must evaluate factors such as the material to be worked on, the type of machining processes involved, and the specific tolerances needed for the final product. This selection process involves a careful balance of functionality, compatibility, and cost-efficiency, as the right fixtures can enhance productivity and reduce errors in manufacturing.

In conclusion, the landscape of engineering fixtures is broad and complex, necessitating a thoughtful approach to selection. By considering expert insights and understanding the fundamental role these fixtures play in engineering projects, professionals can ensure optimal results in their work. Emphasizing this, Dr. Carter's perspective serves as a guiding principle for engineers navigating the intricate interplay between design and manufacturing.

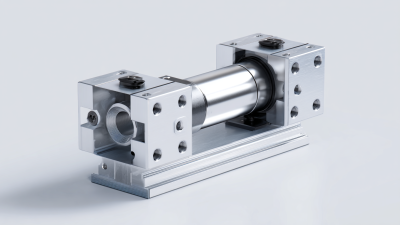

Engineering fixtures play a pivotal role in the success of any project, serving as the backbone for precision and efficiency in manufacturing processes. These fixtures are designed to hold and secure workpieces in place during various operations, ensuring that components are properly aligned and that tolerances are met. By offering stability and repeatability, engineering fixtures minimize errors and enhance productivity, which ultimately leads to a more streamlined workflow.

Moreover, the right engineering fixture can significantly impact the overall quality of the final product. They facilitate complex setups that may not be achievable through standard methods, enabling engineers to focus on innovative designs and functionality without compromising accuracy. As production demands evolve, custom fixtures can be tailored to specific project needs, providing versatility and adaptability in changing operational environments. Understanding the importance of these tools is essential for project managers and engineers alike, as effective use of fixtures not only contributes to cost savings but also strengthens competitive advantage in the marketplace.

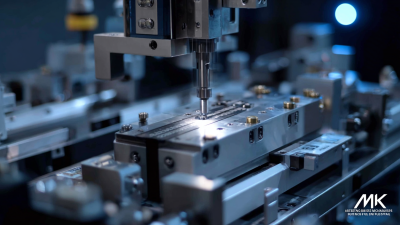

When it comes to engineering projects, selecting the appropriate fixtures is crucial for achieving optimal results. Different applications require specific types of engineering fixtures to meet varying demands. For instance, manufacturing sectors frequently utilize assembly fixtures, while the automotive industry often relies on welding fixtures to ensure precision and repeatability. According to a recent report by the Engineering Fixtures Association, the use of customized fixtures can reduce manufacturing time by up to 30%, emphasizing their importance in enhancing efficiency.

Identifying the correct engineering fixture type involves understanding the specific requirements of your project. For precision machining, tools such as jigs and fixtures that support workpieces tightly without movement are essential. In contrast, inspection fixtures are significant for quality control processes, ensuring that products meet stringent standards before they reach the market. A study published in the Journal of Manufacturing Science highlighted that employing the right type of fixtures could increase production accuracy by 25% and decrease scrap rates by nearly 15%. Selecting the right fixture not only boosts productivity but also plays a vital role in reducing operational costs over time.

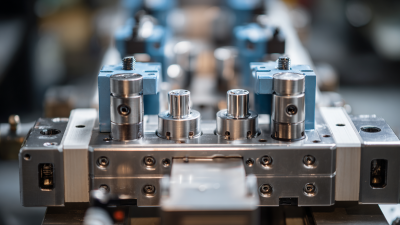

When selecting the right engineering fixtures for your projects, evaluating material options for durability and performance is crucial. Different projects demand different levels of strength, resistance to environmental factors, and overall longevity of the fixtures used. For instance, if the fixtures are intended for outdoor applications, materials such as stainless steel or high-grade aluminum might be warranted due to their corrosion resistance and ability to withstand extreme weather conditions.

On the other hand, for projects requiring precise tolerances and intricate designs, advanced composites or engineered plastics may offer a more suitable balance of strength and weight.

Moreover, it's important to consider the specific conditions the fixtures will encounter during their usage. Factors such as temperature variations, exposure to chemicals, and mechanical stresses can significantly affect material performance. Conducting thorough material testing can help identify which options will perform best under anticipated loads and conditions. By systematically analyzing these factors, engineers can ensure that the selected materials not only enhance the overall effectiveness of the fixtures but also extend their operational lifespan. Understanding these nuances in material selection directly contributes to project success, leading to enhanced productivity and reduced maintenance costs.

When selecting engineering fixtures for your projects, several key factors should be taken into account to ensure optimal performance and efficiency. First and foremost, it is essential to assess the specific requirements of your project, including the type of components you will be working with and the tolerances needed during production. This understanding will guide you in determining the appropriate materials and designs that will best suit your application's demands.

Additionally, consider the manufacturing process and workflow involved. The ease of assembly, adjustment, and adaptability of the fixtures can greatly influence productivity. Fixtures that facilitate quick setup and changes can minimize downtime and streamline operations. Lastly, evaluate the durability and maintenance requirements of the fixtures. Investing in robust, low-maintenance fixtures can lead to long-term cost savings and reduce the frequency of replacements. By carefully considering these factors, you can make informed choices that enhance the efficiency and success of your engineering projects.

When it comes to implementing engineering fixtures in your workflow, adhering to best practices is essential for maximizing efficiency and ensuring quality. According to a report by the American Society of Mechanical Engineers (ASME), projects that effectively utilize engineering fixtures can improve assembly accuracy by up to 70% and reduce production times by as much as 30%. This underscores the importance of selecting the right fixtures based on the specific needs of your project.

One of the best practices is to start by carefully defining the operational requirements of your project. Consider factors such as the type of materials being used, the complexity of the components, and the precision required in the final assembly. A study from the Society of Manufacturing Engineers (SME) emphasizes that aligning fixture design with process capabilities can lead to significant reductions in waste and an increase in overall productivity. Additionally, it's crucial to involve cross-functional teams in the design and implementation phase to ensure that all perspectives are considered, which can lead to innovative solutions that enhance workflow efficiency.

| Fixture Type | Material | Application | Adjustability | Cost ($) |

|---|---|---|---|---|

| Welding Fixture | Steel | Automotive Manufacturing | Fixed | 1500 |

| Assembly Fixture | Aluminum | Electronics Assembly | Adjustable | 1200 |

| Drilling Fixture | Plastic | Aerospace Components | Fixed | 800 |

| Inspection Fixture | Composite | Quality Control | Adjustable | 1000 |

| Clamping Fixture | Titanium | Medical Devices | Adjustable | 2000 |