In today's rapidly evolving industrial landscape, selecting the right Aluminium Parts is crucial for maintaining competitive advantage. According to a 2021 report by Research and Markets, the global aluminium market is projected to reach USD 250 billion by 2026, driven largely by the automotive and aerospace sectors which increasingly prefer lightweight yet durable materials. Additionally, a report from Statista indicated that demand for aluminium components in the building and construction industry is anticipated to grow at a CAGR of 5.4% from 2022 to 2028. As industries strive to enhance efficiency and reduce costs, understanding market trends and material specifications becomes essential for companies aiming to optimize their production processes. Therefore, this guide aims to provide critical insights on how to effectively choose Aluminium Parts tailored to the unique needs of various industries, ensuring both performance and sustainability.

Aluminium parts have become increasingly vital across various industries due to their lightweight nature, corrosion resistance, and versatility. In the automotive sector, for example, aluminium components are essential for enhancing fuel efficiency while maintaining structural integrity. This trend is driven by a growing demand for electric vehicles (EVs) and a focus on sustainability, prompting manufacturers to adopt aluminium in production for better performance and lower emissions.

In the aerospace industry, aluminium is favored for its strength-to-weight ratio, making it an ideal choice for aircraft components where reducing weight is paramount. With advancements in aluminium alloys and coatings, the material is now better equipped to withstand extreme conditions, providing safety and reliability. Similarly, the construction industry is leveraging aluminium for architectural applications; its malleability allows for innovative designs while offering durability against environmental challenges. Identifying these key applications not only helps in aligning product offerings with market needs but also drives innovation in material usage across sectors.

In the aerospace industry, aluminium is favored for its strength-to-weight ratio, making it an ideal choice for aircraft components where reducing weight is paramount. With advancements in aluminium alloys and coatings, the material is now better equipped to withstand extreme conditions, providing safety and reliability. Similarly, the construction industry is leveraging aluminium for architectural applications; its malleability allows for innovative designs while offering durability against environmental challenges. Identifying these key applications not only helps in aligning product offerings with market needs but also drives innovation in material usage across sectors.

When selecting aluminium parts for industry applications, evaluating the performance characteristics of aluminium alloys is crucial. Aluminium alloys are categorized primarily into two types: wrought and casting, each possessing unique properties that make them suitable for specific applications. According to a report by the Aluminium Association, wrought alloys, such as the 6000 series, provide excellent corrosion resistance and good weldability, making them ideal for structural applications in construction and transportation. In contrast, casting alloys like the 300 series are preferred in manufacturing components that require complex geometries and high strength, such as automotive engine parts.

Market trends emphasize the increasing adoption of lightweight materials in industries such as aerospace and automotive, driven by the need for fuel efficiency and lower emissions. A study from ResearchAndMarkets indicates that the global aluminium alloy market is expected to reach $145 billion by 2025, with a compound annual growth rate (CAGR) of 5.2%. This growth is largely influenced by advancements in alloy technology that enhance properties such as tensile strength and thermal conductivity. For instance, the development of high-strength aluminium-lithium alloys has resulted in materials that are not only lighter but also exhibit superior mechanical properties, making them attractive options for manufacturers striving for performance and sustainability.

When choosing aluminium parts for your industry needs, it is crucial to stay informed about current market trends that can significantly affect your selections. Industries ranging from automotive to aerospace are witnessing a surge in demand for lightweight, durable, and corrosion-resistant materials. As sustainability becomes a key focus, many manufacturers are investing in recycled aluminium, which not only reduces production costs but also appeals to eco-conscious consumers. Keeping an eye on these trends can help you make more informed decisions when sourcing aluminium components.

**Tips:** Always analyze the longevity and performance characteristics of aluminium alloys available in your sector. This will ensure you select parts that not only meet your immediate needs but also provide reliability over time. Additionally, consider collaborating with suppliers who have a firm grasp on market trends and can offer insights into the best materials suited for your application.

Another significant trend is the digitalization of manufacturing processes, which allows for better design precision and efficiency. Automation technologies are enhancing the production of aluminium components, enabling custom solutions tailored to specific industry requirements. By embracing these advancements, companies can improve production timelines and reduce waste, thereby optimizing overall project costs.

**Tips:** Stay updated on technological innovations within the aluminium industry, as this can greatly affect your procurement strategy and production capabilities. Networking with industry experts can also provide valuable insights that guide your selection process.

| Industry | Common Aluminium Parts | Market Trend (2023) | Key Factors Driving Demand |

|---|---|---|---|

| Automotive | Engine components, Housings | Increased electric vehicle production | Lightweight materials, Fuel efficiency regulations |

| Aerospace | Airframe, Wing components | Growing air travel demand | Regulatory standards, Innovation in design |

| Construction | Window frames, Structural beams | Rise in urbanization projects | Sustainability requirements, Energy efficiency |

| Electronics | Casing, Heat sinks | Increased consumer electronics demand | Miniaturization, High-performance requirements |

| Marine | Boat hulls, Engine parts | Growing recreational boating market | Corrosion resistance, Weight reduction |

In today's competitive landscape, the importance of certification and quality standards cannot be overstated. As industries adopt Total Quality Management (TQM) practices, companies are witnessing elevated efficiency and enhanced customer satisfaction. Emphasizing the necessity of international certifications, such as ISO 9001 and ISO 14001, firms can align their operations with globally recognized quality and environmental management criteria, thereby fostering sustainable development. Reports suggest that organizations with ISO certification experience up to a 30% improvement in overall performance metrics, including customer retention rates.

Tips for choosing the right aluminium parts include verifying the manufacturer’s certifications. Ensure they comply with industry standards such as ISO, which serves as a benchmark for quality assurance in product delivery. Additionally, consider the sustainability aspect; suppliers with ISO 14001 certifications demonstrate a commitment to environmental management, crucial for meeting consumer demands in 2025 and beyond.

Furthermore, staying updated on market trends can provide insights into quality improvements. For instance, the upcoming revisions to ISO 9001 in 2026 will directly address the integration of technology and AI in quality management systems. By proactively adapting to these changes and prioritizing certified products, businesses can position themselves for success in a rapidly evolving industry landscape.

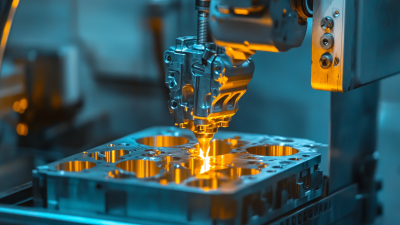

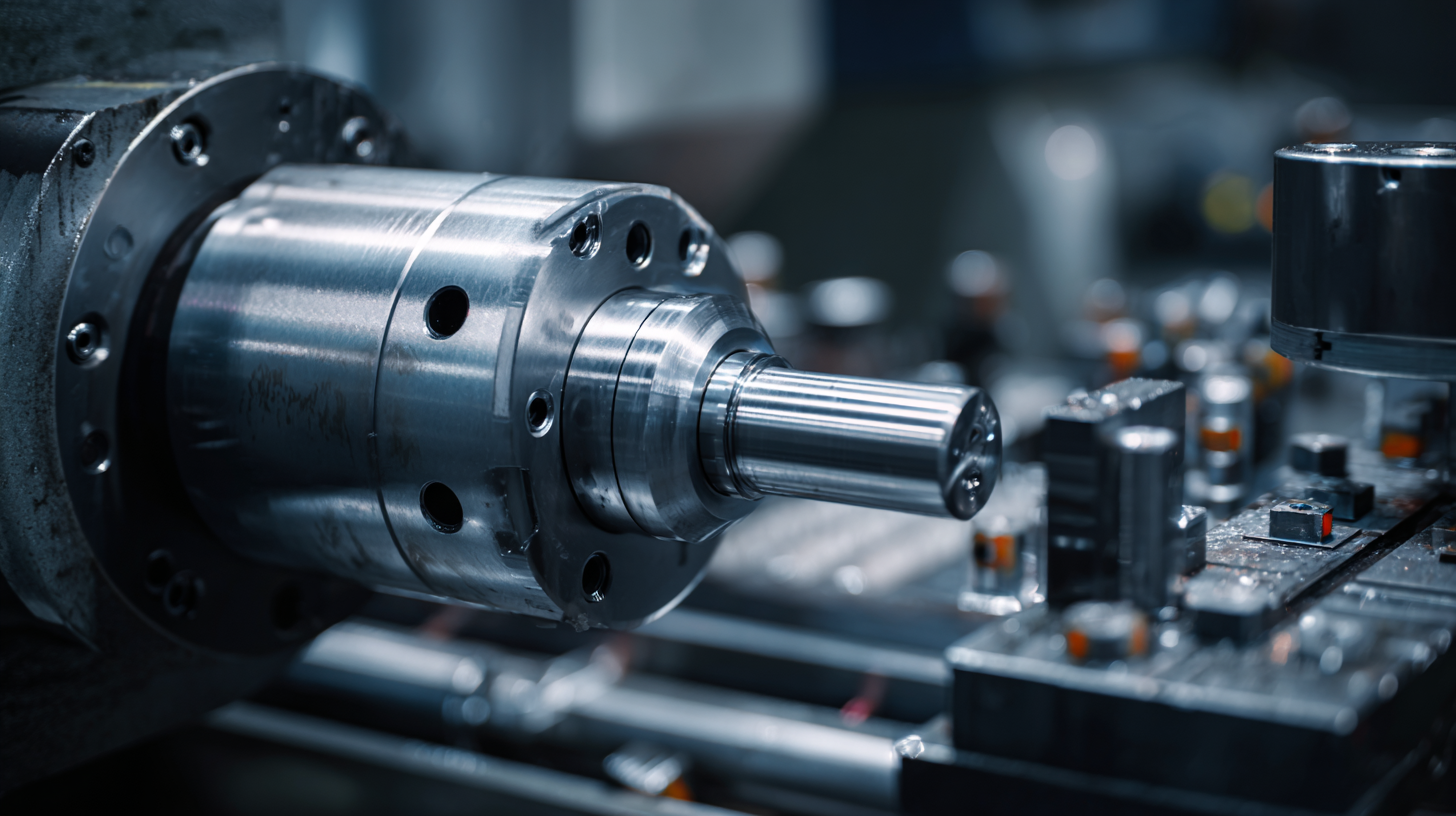

When selecting aluminium parts for specific industrial applications, understanding the cost-effectiveness of various aluminium manufacturing processes is crucial. A recent report by the Aluminium Association reveals that advanced manufacturing techniques, such as additive manufacturing and precision casting, can significantly reduce material waste. For instance, additive manufacturing can achieve material efficiencies of over 90%, leading to decreased costs and a smaller environmental footprint compared to traditional methods like die casting, which typically realizes around 60-70% efficiency.

Additionally, process selection can be influenced by the overall production volume. The report indicates that for high-volume production, processes such as extrusion and forging tend to offer better economies of scale, with costs reducing by up to 30% as production increases. On the other hand, for low-volume applications, methods like CNC machining may present higher costs due to longer setup times but can be justified by the unique specifications and tighter tolerances they provide. Understanding these nuances in cost-effectiveness is vital for industries aiming to optimize their aluminium sourcing and manufacturing strategies in light of the latest market trends.

This chart illustrates the cost-effectiveness of various aluminium manufacturing processes. The prices range from Die Casting at $5.0 per kg to 3D Printing at $10.0 per kg, thereby helping industries to make informed decisions based on market trends.