Choosing the right weld fixture tooling is crucial for any welding project. A well-designed fixture can enhance precision and efficiency. Conversely, poor tooling can lead to errors and waste.

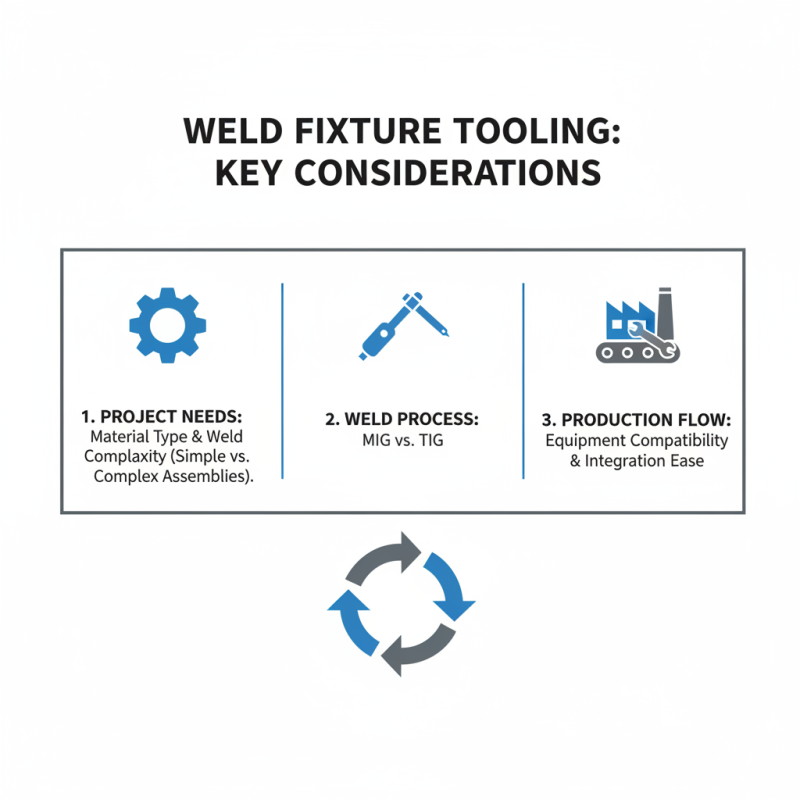

When selecting weld fixture tooling, consider your specific project requirements. Think about the materials you’ll work with and the complexity of your design. These factors significantly influence the tooling choice.

Many forget to evaluate their budget accurately. Keep in mind that high quality often comes with higher costs. Nonetheless, investing in the right weld fixture tooling is essential for long-term productivity. Balancing cost and quality is vital. Think carefully before making decisions.

Choosing the right weld fixture tooling starts with understanding your project's specific requirements. Each project differs; unique dimensions, materials, and joint types play a role. You must assess these elements to create an effective tooling strategy. Consider the weight and size of components. These factors impact not just the design but also the tooling's overall functionality.

Tips for assessing requirements: collect data on your components early. Sketch the welding layout. Think about accessibility for welding equipment. Don’t overlook the finishing process; it can affect your choice of tooling. Sometimes, what seems perfect in theory may not fit in practice. Test different configurations if possible.

Quality matters greatly in weld fixtures. If you're unsure about your designs, seek feedback from your team. This process can reveal overlooked details. Team input can also highlight potential issues. Remember, tool selection impacts precision and efficiency. Embrace imperfections; refining your approach can lead to better solutions. Frequent reassessment is key.

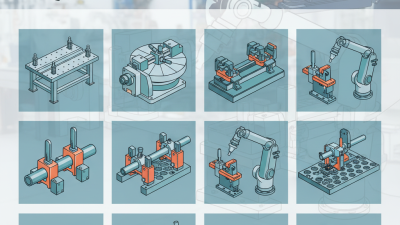

When selecting weld fixture tools, it's important to understand the different types available. Common types include manual fixtures, automatic fixtures, and modular systems. Manual fixtures are great for small-scale projects. They allow for quick adjustments and versatility. However, they require a skilled hand to ensure precision. Automatic fixtures increase productivity and are ideal for mass production. Yet, they often come with a higher upfront cost.

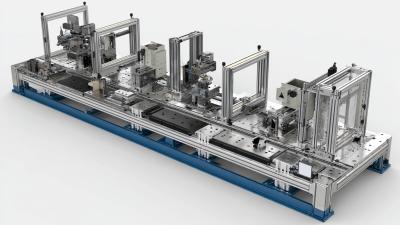

Modular systems offer flexibility. They can adapt to various designs and sizes. This makes them suitable for projects that require frequent changes. Consider your project needs before choosing. A tool that works for one project might not suit another.

**Tips:** Always test your fixtures before mass production. This can save time and costly errors. Review your setup at each stage. Ensuring proper alignment can prevent issues down the line. Seek feedback from your team on the tooling process. Sometimes, fresh eyes can catch problems you might overlook.

| Type of Weld Fixture Tool | Description | Applications | Advantages |

|---|---|---|---|

| Fixed Weld Fixtures | Provide a stationary platform for consistent and repeatable welding. | High-volume production of parts with minimal variations. | Increased accuracy and reduced labor time. |

| Adjustable Weld Fixtures | Allow for modifications to accommodate different parts and configurations. | Production runs with varying parts and dimensions. | Flexibility in production and cost-effectiveness. |

| Electromagnetic Fixtures | Use magnetic forces to secure metal parts during welding. | Lightweight and thin metal parts. | Quick setup and repositioning for different parts. |

| Self-Locating Fixtures | Utilize design features of the parts to automatically position them. | Automated assembly lines for complex assemblies. | Reduced setup times and enhanced repeatability. |

| Custom Fixtures | Designed specifically for a particular project or part. | Unique or specialized components. | Optimized for specific tasks, increasing productivity. |

Selecting the right weld fixture tooling is critical to project success. When considering options, prioritize the materials used in the tooling.

High-quality materials can withstand heat and stress, reducing warping and extending the tool's lifespan. According to industry reports, using durable materials can improve production efficiency by up to 25%.

Next, evaluate the design flexibility of the tooling. A well-designed fixture allows for easy adjustments, accommodating various welds. Research shows that customizable options can enhance workflow and minimize downtime.

This adaptability can be a game changer, particularly for projects with diverse requirements.

Cost is another essential factor. While high-end tools offer benefits, they may not suit every budget.

Balancing quality and price is crucial. Investing in a slightly more expensive tool can lead to savings over time. However, ensure the tooling meets your specific needs. Sometimes, settling for cheaper options can result in higher long-term costs due to frequent repairs or replacements.

Evaluating the cost-effectiveness of weld fixture solutions is crucial for any engineering project. According to a recent industry report, custom weld fixtures can reduce assembly time by up to 30%. This improvement leads to direct savings, as labor costs account for nearly 40% of total manufacturing expenses. Choosing the right tooling becomes vital for maximizing efficiency and keeping budget constraints in check.

However, the initial investment in weld fixture tooling can be daunting. Many projects overlook the long-term benefits and the potential for reduced rework. A study indicates that high-quality fixtures decrease the likelihood of defects by 25%. This not only enhances product quality but also minimizes costs associated with returns and replacements. Reflection on upfront costs versus long-term gains is necessary.

Cost assessments should include maintenance considerations. While a lower-priced fixture may seem appealing, it could incur higher repair costs. A report from an industry consortium highlights that over 50% of fixtures require adjustments within their first year of use. This leads to additional downtime and lost productivity. Evaluating both initial expenses and future needs is essential for making informed decisions in tool procurement.

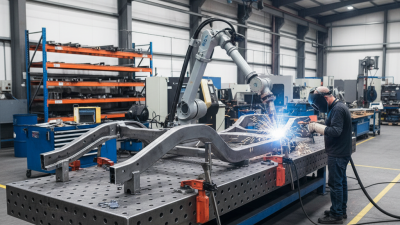

When implementing weld fixture tooling in production, careful consideration is crucial. Start by analyzing your project's specific needs. Identify the materials you'll be working with and the complexity of the welds required. For example, simple joints may not need elaborate fixtures, while complex assemblies typically do. Assess the types of welds, whether you’re using MIG or TIG processes. Equipment compatibility matters, as does the ease of integration into your current workflow.

Tooling geometry is another key factor. Ensure that the fixtures allow for proper access and visibility for welding operations. Poor visibility can lead to mistakes and rework, causing delays. Think about modular fixtures too, which can adapt as project requirements change. However, avoid overspending; sometimes simpler is better.

Lastly, gather feedback from the welding team. They often have valuable insights into fixture performance. If challenges arise, reflect on those issues. Don’t hesitate to make adjustments based on real-world usage. The goal is continuous improvement in your production process. This might mean trial and error, but it leads to better outcomes.