Selecting the right Die Fixture for CNC machining is crucial for achieving precision and efficiency in manufacturing processes. According to John Smithson, a renowned expert in the die and fixture industry, "The success of a machining operation often hinges on the quality and suitability of the die fixture used." His insights emphasize that understanding the nuances of different die fixtures can significantly impact the final product's quality.

When navigating the complexities of CNC machining, choosing an appropriate die fixture involves considering factors such as material compatibility, design specifications, and production volume. It is essential to assess the requirements of each project to ensure that the selected die fixture can accommodate specific machining needs effectively.

Furthermore, the right die fixture not only streamlines the machining process but also enhances productivity and reduces the likelihood of errors. By prioritizing these considerations, manufacturers can leverage the full potential of their CNC machinery and produce high-quality components consistently. In this guide, we will delve into the critical aspects of selecting a die fixture that aligns with your CNC machining requirements, ensuring optimal operational outcomes.

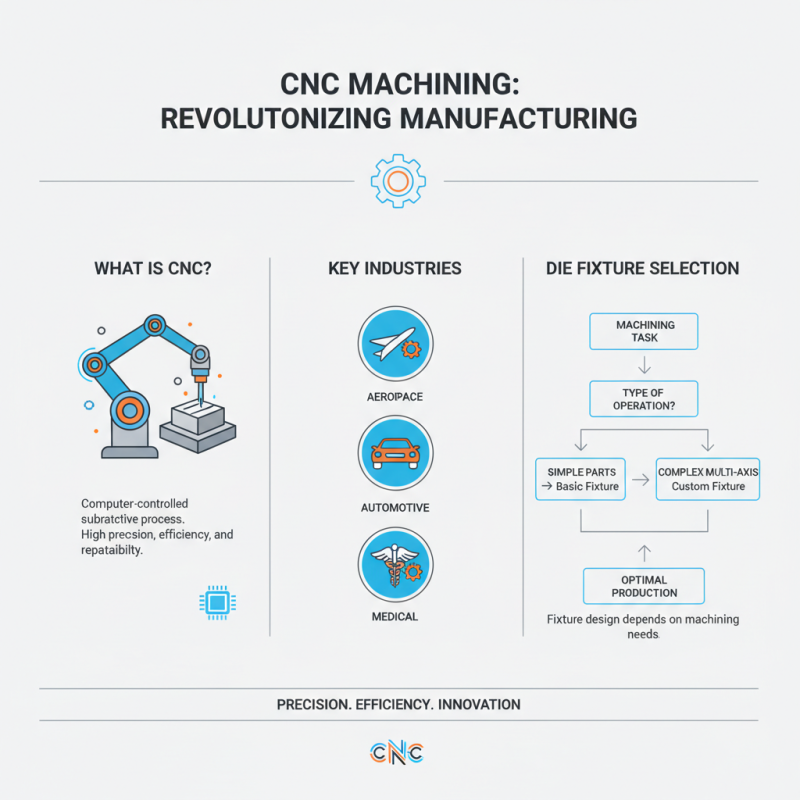

CNC machining has revolutionized the manufacturing industry by providing precise and efficient production methods across various applications. This computer-controlled process allows for highly detailed and consistent results, making it ideal for industries such as aerospace, automotive, and medical. Understanding the fundamentals of CNC machining is essential for selecting the right die fixture, as the type of machining task directly influences the fixture's design and utility. Applications range from simple part production to complex multi-axis operations, highlighting the importance of customization in die fixture selection to meet specific project requirements.

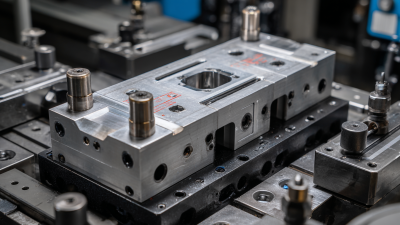

The die fixture plays a crucial role in the CNC machining process by securing the workpiece and ensuring accurate machining operations. It must be tailored to the shape and size of the parts being produced, as well as the type of machining being utilized. Factors such as material compatibility, ease of loading and unloading, and the ability to withstand machining forces must be considered when choosing a die fixture. Proper alignment is also critical to achieving tolerances and minimizing errors, underscoring the need for a thorough understanding of the machining application when making this important decision.

Die fixtures play a crucial role in CNC machining processes by ensuring that the workpiece is held securely and accurately during operations. The significance of selecting the appropriate die fixture cannot be overstated, as it directly impacts the precision, efficiency, and quality of the finished product. The right fixture minimizes errors, reduces setup time, and enhances overall productivity, allowing for more complex designs to be executed with ease.

When choosing a die fixture, it’s important to consider a few tips to ensure optimal results. First, assess the specific requirements of your project, such as the shape and size of the workpiece, the type of machining operation, and the material being used. This will guide you in selecting a fixture that complements your machining needs. Second, consider the adjustability and versatility of the fixture; options that allow for quick adjustments can significantly reduce downtime between production runs.

Additionally, pay attention to the material and construction of the fixture. Materials that offer durability and rigidity will provide better support and maintain accuracy over time. Investing in high-quality construction can lead to long-term gains by minimizing wear and tear. By carefully evaluating these factors, you can ensure that your CNC machining processes are both effective and efficient, ultimately delivering superior results in your manufacturing endeavors.

Understanding the importance of die fixtures in CNC machining can help improve productivity and precision in manufacturing processes. The following bar chart illustrates the significance of various factors to consider when selecting die fixtures.

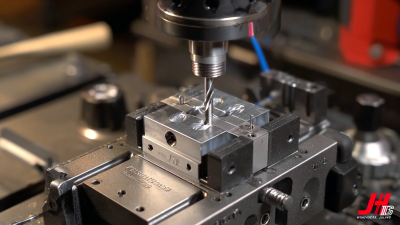

When selecting the right die fixture for CNC machining, several key factors must be considered to ensure optimal performance and efficiency. Firstly, the design complexity of the parts being manufactured plays a crucial role. Studies indicate that fixtures which accommodate complex geometries can improve machining accuracy by up to 25%, as they better stabilize the workpiece and reduce vibrations during the cutting process. Understanding the specific requirements of the part, such as tolerance levels and surface finish, will aid in selecting a fixture that maintains these standards.

Another critical factor is the material of the die fixture. The choice of material can significantly impact the longevity and reliability of the fixture. Industry reports suggest that using high-strength steel or aluminum alloys can not only enhance the fixture's resistance to wear but also reduce overall weight, improving machine dynamics. Additionally, the compatibility of the fixture with existing CNC equipment should be evaluated. A well-matched fixture and machine tool pairing can increase machining productivity by up to 30%, minimizing setup time and ensuring a seamless workflow.

By focusing on these considerations, manufacturers can better align their die fixture choices with their specific CNC machining needs, leading to improved efficiency and reduced operational costs.

When selecting the right die fixture for CNC machining, understanding the different types available and their specific applications is crucial. Die fixtures serve as the backbone of production, holding and supporting workpieces during machining processes. Among the various types, two commonly used fixtures are the modular die fixtures and dedicated die fixtures. According to a report by MarketsandMarkets, the CNC machining market is projected to reach $100 billion by 2025, highlighting the significance of utilizing the appropriate fixtures for efficiency.

Modular die fixtures are known for their versatility, allowing manufacturers to tailor setups based on varying workpiece sizes and shapes. This flexibility is particularly advantageous in environments with diverse production runs. On the other hand, dedicated die fixtures are designed for a specific part, which often results in faster setup times and improved precision. A study conducted by the American Society of Mechanical Engineers indicated that using dedicated fixtures can enhance machining accuracy by up to 30%, thereby optimizing production efficiency and reducing waste.

In addition, the integration of advanced technologies such as computer-aided design (CAD) and additive manufacturing in die fixture development is revolutionizing the sector. These innovations enable manufacturers to create fixtures that not only support but also align with complex geometries, offering advantages like improved repeatability and reduced cycle times. As the CNC machining landscape continues to evolve, choosing the right die fixture becomes essential for maximizing productivity and ensuring high-quality outcomes.

| Fixture Type | Material | Best Use Case | Advantages | Limitations |

|---|---|---|---|---|

| Standard Die Fixture | Aluminum | General machining tasks | Lightweight, easy to handle | Less durable than steel |

| Steel Die Fixture | Steel | Heavy-duty machining | High durability, stability | Heavier and more difficult to set up |

| Adjustable Die Fixture | Steel or Aluminum | Variety of workpieces | Versatile and flexible | Set-up time can be longer |

| Vacuum Die Fixture | Composite materials | Thin or delicate materials | Gentle holding, minimal distortion | Not suitable for heavy workpieces |

| Magnetic Die Fixture | Steel | Flat and ferrous workpieces | Quick setup, no clamps needed | Limited to magnetic materials |

When it comes to CNC machining, maintaining die fixtures is crucial for ensuring precision and longevity. Regular maintenance not only enhances the performance of fixtures but also reduces the risk of wear and tear that could compromise production quality. One key aspect to focus on is cleanliness; ensuring that fixtures are free from debris and contaminants can prevent unplanned downtime and mishaps during machining processes.

Tips: Always clean your die fixtures after each use. Use appropriate cleaning solutions that do not cause corrosion to the materials of the fixture. This simple step can significantly extend the life of your equipment.

Another important practice is to regularly inspect die fixtures for any signs of defects or wear. This includes checking for cracks, misalignment, and deviations in surface finish. Early detection of issues can save costs in the long run, as addressing minor problems promptly can prevent larger, more expensive repairs. Additionally, recalibrating fixtures periodically can help in maintaining the required tolerances, thereby ensuring the accuracy of the machined parts.

Tips: Implement a routine schedule for inspections and calibrations. Keeping a log of maintenance activities can help track fixture performance and identify patterns that may indicate underlying problems.