In the automotive industry, precision is critical. A Car Checking Fixture serves as an essential tool in ensuring vehicle inspections are accurate. According to a report by the Automotive Research Institute, over 30% of vehicles fail initial inspections due to calibration issues. This alarming statistic highlights the importance of reliable inspection tools.

Expert Mike Johnson, a renowned figure in automotive quality control, emphasizes the significance of the Car Checking Fixture. He states, “Using the right fixture can significantly reduce inspection errors and improve overall vehicle safety.” This statement encapsulates the urgent need for high-quality fixtures in vehicle assessments.

Moreover, while the technology behind Car Checking Fixtures has advanced, not all fixtures are created equal. Many technicians still struggle with choosing appropriate fixtures or fail to use them correctly. This inconsistency raises questions about inspection processes. Investing in training can help bridge these gaps and enhance the use of Car Checking Fixtures in the industry.

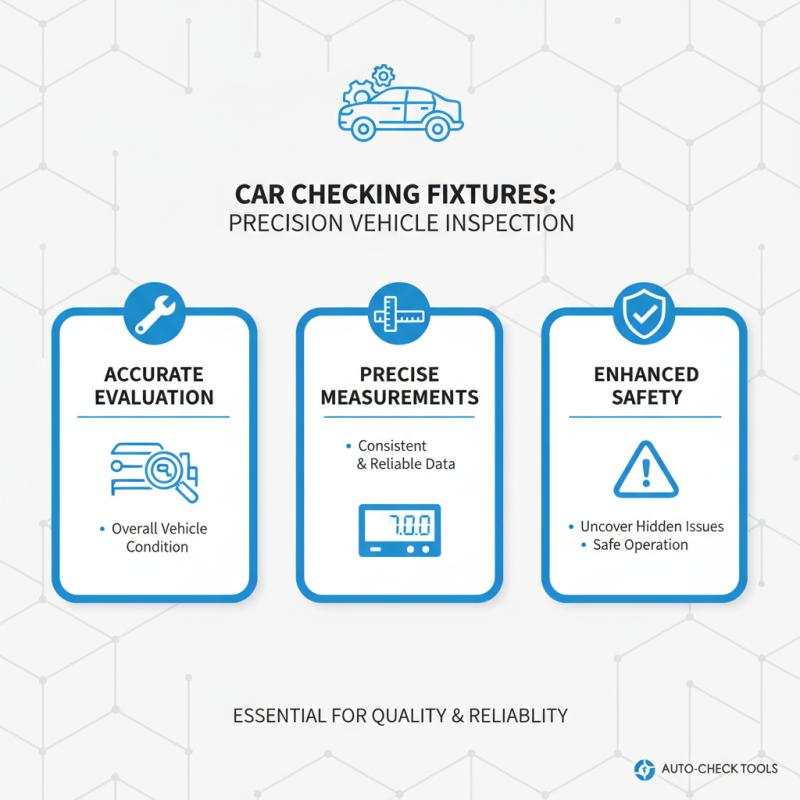

Car checking fixtures play a critical role in vehicle inspections. These tools help technicians evaluate the overall condition of a vehicle accurately. They ensure that measurements are precise and consistent, which is essential for safe operation. Proper use of these fixtures can uncover issues that might otherwise go unnoticed.

Understanding the importance of car checking fixtures is vital. They allow for efficient inspections and help in maintaining quality. Many technicians overlook their significance, leading to potential safety hazards. It's easy to underestimate the details. A small misalignment can affect performance. Using the right fixtures can prevent this.

Training and familiarizing oneself with these tools is necessary. Some might find it tedious, but it's essential to avoid inspection errors. Without proper checking fixtures, the risk of overlooking critical faults increases. Technicians should reflect on their practices regularly. Continuous improvement in inspection techniques can greatly enhance vehicle safety.

When it comes to vehicle inspections, car checking fixtures play a crucial role. These tools ensure that all components of a vehicle are thoroughly examined for safety and performance. Various types of fixtures serve this purpose, each designed for specific inspection tasks. For instance, alignment fixtures help evaluate the precise positioning of wheels and suspension components, critical for maintaining vehicle stability.

Another important type is measuring fixtures. These tools assess the dimensions of various parts, ensuring they meet manufacturer specifications. Research shows that using precise measuring tools can reduce inspection errors by up to 30%. This enhancement leads to improved safety and fewer vehicle recalls. The right fixture also contributes to time efficiency during inspections.

Tips: Always verify the calibration of your checking fixtures before use. Regular maintenance of these tools is essential to ensure reliability. Also, consider training inspectors on the latest techniques for using these fixtures. An informed team can significantly impact overall inspection quality. Remember, even small errors in assessments can lead to significant safety issues down the line.

Setting up car checking fixtures involves careful planning and execution. Begin by selecting the right fixtures. These should align with your inspection goals. According to a 2021 industry report, accurate fixtures can reduce inspection errors by 25%. Each fixture must accommodate various vehicle types. Proper selection ensures that you can inspect everything from compact cars to large SUVs effectively.

Next, configure the fixtures. Space them out to avoid overcrowding. Poor organization often leads to unnecessary mistakes. Ensure that each fixture is labeled clearly. This helps technicians find the correct tool quickly. A study highlighted that 30% of vehicle inspection delays stem from disorganization. Consider incorporating visual aids, like diagrams, to enhance clarity.

After setup, test your fixtures. Run a few mock inspections to identify any flaws. Are there any areas that feel cumbersome? Reflections on the process are crucial. Gather feedback from your team. They may spot issues you overlooked. Addressing these problems early helps maintain accuracy during actual inspections. Regularly reassess your fixtures for effectiveness and efficiency.

Accurate vehicle inspections are crucial for safety. Using car checking fixtures can enhance the precision of these inspections significantly. According to a report from the National Highway Traffic Safety Administration, ineffective inspections can lead to 25% of road accidents. Hence, employing fixtures allows for a thorough assessment of critical components like brakes and tires.

Best practices involve strategic positioning of the fixtures. Ensure they align correctly with the vehicle's specifications. The Society of Automotive Engineers states that 70% of inspection failures stem from misalignment. Technicians should regularly calibrate these fixtures. Consistent calibration ensures that readings stay reliable. Lighting conditions also matter; proper illumination helps in detecting flaws.

Documentation is key. Keeping detailed records of each inspection creates accountability. Data indicates that vehicles with thorough inspection histories have a 30% lower chance of failure in subsequent checks. Inspections should not be rushed. Take time to scrutinize every detail, no matter how minor it may seem. This diligence will ultimately lead to safer roads.

When using car checking fixtures, avoid common mistakes for more accurate inspections. Many professionals overlook calibration. A 2021 study by the Automotive Service Association indicates that 30% of inspection errors stem from uncalibrated tools. Failing to calibrate your fixtures can lead to misreadings. Regular checks are essential to ensure tools provide reliable data.

Another common mistake is improper placement of the vehicle. According to a report by the National Institute for Automotive Service Excellence, misaligned vehicles contribute to nearly 25% of faulty inspections. Ensure that the vehicle is level and secure. A small error in positioning can lead to significant discrepancies in results.

Lastly, don’t skip the documentation process. Inaccurate records can create a false sense of confidence. A survey from the Institute of Automotive Engineers found that 40% of vehicle misdiagnoses were due to insufficient data collection. Always take note of inspection conditions. This practice can help identify trends over time.