In the automotive manufacturing industry, quality control is of paramount importance, ensuring that each vehicle meets the highest standards before it reaches the consumer. One integral component for enhancing this quality assurance process is the "Car Checking Fixture." According to industry expert Dr. Emily Tran, a leading authority in automotive quality systems, "Implementing a Car Checking Fixture can significantly reduce error rates and streamline production, ultimately leading to greater customer satisfaction."

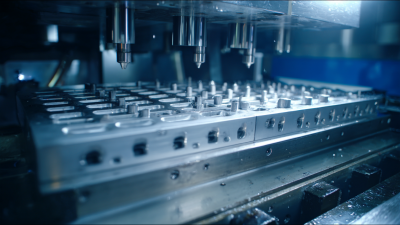

Car Checking Fixtures are specialized tools designed to verify the dimensions and assembly of vehicle components. By providing a precise and consistent method of measurement, these fixtures not only minimize the risk of defects but also facilitate quicker assembly processes. The role of these fixtures in quality control cannot be overstated, as they serve as the first line of defense against manufacturing errors.

In an era where customer expectations are continually rising, automotive manufacturers must adopt innovative solutions like Car Checking Fixtures. The adoption of these tools not only enhances accuracy but also fosters a culture of excellence within the production line. As such, understanding and effectively implementing a Car Checking Fixture can lead to significant improvements in overall quality control, driving the industry towards a more reliable future.

A car checking fixture is a specialized tool used in the automotive manufacturing process to ensure that vehicle components are produced to precise specifications. These fixtures are designed to simulate real-world conditions, allowing manufacturers to verify the alignment, fit, and function of parts before moving on to assembly. By utilizing these fixtures, manufacturers can identify discrepancies early, which significantly reduces the likelihood of defects making it to the consumer.

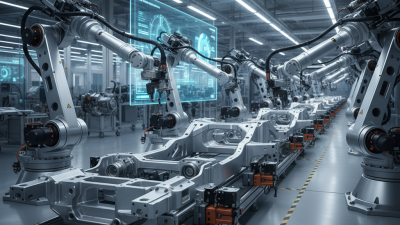

According to a report by the Automotive Industry Action Group (AIAG), implementing advanced quality control measures, such as car checking fixtures, can decrease production errors by up to 30%. This not only enhances product quality but also optimizes the manufacturing process, leading to lower costs associated with rework and scrap material. With the automotive sector facing increasing consumer expectations for quality and reliability, the integration of car checking fixtures becomes critical. Their role in maintaining tight tolerances and facilitating efficient inspections ultimately supports manufacturers in achieving quality assurance standards, such as ISO/TS 16949, which emphasizes continual improvement and defect prevention.

Car checking fixtures are essential tools in the automotive industry, designed to ensure everything from alignment to safety measures meet high standards. These fixtures typically include several key components: a base, locating elements, and clamping devices. The base provides a stable platform that supports the entire structure, while the locating elements ensure that all parts of the vehicle are positioned correctly for verification. Clamping devices are crucial as they secure the vehicle components in place during inspection, preventing any movement that could lead to inaccurate measurements.

When it comes to improving quality control, the design of the car checking fixture plays a significant role. A well-structured fixture minimizes human error and enhances repeatability in measurements. By incorporating adjustable and customizable features, manufacturers can cater to various vehicle models and specifications, improving the utility of the fixture across multiple applications.

Tips: To optimize the effectiveness of a car checking fixture, ensure that the components are made from durable materials that can withstand repeated use. Regular maintenance and calibration checks can also enhance accuracy over time, ensuring that the quality control processes remain reliable and efficient. Furthermore, involving operators in the design process can lead to practical enhancements based on their hands-on experience.

Car checking fixtures play a pivotal role in enhancing quality control within the automotive industry. These fixtures are used to verify the dimensional accuracy of car components during the manufacturing process, ensuring that each part meets stringent specifications. According to a report by the National Institute of Standards and Technology (NIST), implementing precise checking fixtures can lead to a reduction in manufacturing defects by as much as 30%, significantly improving overall production efficiency.

Moreover, the use of car checking fixtures contributes to more streamlined workflows on the assembly line. A study conducted by the Automotive Industry Action Group (AIAG) highlighted that facilities utilizing advanced checking fixtures reported a 20% increase in throughput due to minimized rework and faster inspection processes. This not only enhances the quality of the end product but also reduces waste, aligning with modern sustainability initiatives within the industry. By integrating car checking fixtures into their quality control strategies, manufacturers can achieve a more reliable and consistent output, ultimately leading to increased customer satisfaction.

Car checking fixtures play a crucial role in enhancing quality control within the automotive manufacturing industry. These specialized tools are designed to hold and align car components accurately during the inspection process. By providing precise measurements and consistent positioning, car checking fixtures help to identify any discrepancies early in the manufacturing cycle. This proactive approach minimizes the risk of defects reaching the final assembly, ensuring a higher level of quality in the finished product.

One of the key benefits of using car checking fixtures is the significant improvement in efficiency. They streamline the inspection process, allowing manufacturers to quickly assess components without extensive manual measurement techniques. This not only saves time but also reduces labor costs and the likelihood of human error. Additionally, fixtures can be customized for different models and parts, making them versatile tools in a dynamic manufacturing environment.

Tips for maximizing the effectiveness of car checking fixtures include regular calibration to maintain measurement accuracy, and integrating them within a robust quality management system. Furthermore, it is beneficial to train staff on using these fixtures properly to ensure that the inspection process is efficient and reliable. Investing in high-quality materials for the fixtures can also enhance their durability and longevity, providing better returns in the long run.

Car checking fixtures play a vital role in the automotive industry, enhancing quality control by providing precise measurements and ensuring parts fit together as designed. According to a report from the International Automotive Quality Conference, approximately 30% of manufacturing defects stem from improper alignment and fitment of components. Car checking fixtures help mitigate these issues by offering a standardized method to validate the dimensions and assembly of parts throughout the production process. This not only reduces waste but also improves overall product reliability and customer satisfaction.

In terms of common applications, car checking fixtures are extensively utilized during various stages of vehicle assembly, from body-in-white inspections to final assembly checks. For instance, during the body assembly phase, fixtures are employed to verify that the critical dimensions of the car's frame align correctly before proceeding to the painting and interior installation phases. A study published in the Journal of Automotive Engineering suggests that using dedicated checking fixtures can reduce assembly errors by up to 25%, significantly lowering rework costs and improving delivery timelines. Additionally, fixtures are often used in prototype testing to ensure design feasibility, guaranteeing that any adjustments can be made early in the development process, thus streamlining production efficiency and enhancing quality control measures.