In the pursuit of excellence in manufacturing, the implementation of a Comprehensive Checking Fixture (CCF) is crucial for quality assurance across various industries. According to a report by the Quality Assurance Institute, 70% of organizations face challenges in meeting quality standards due to insufficient inspection tools. Comprehensive Checking Fixtures provide a robust solution by allowing for systematic and accurate measurement of critical dimensions, ensuring that components meet predefined specifications. Furthermore, recent studies indicate that businesses employing CCFs can reduce defect rates by up to 40%, significantly enhancing product reliability and customer satisfaction. As industries continue to evolve, integrating comprehensive checking fixtures in quality control processes not only mitigates risks but also supports compliance with increasingly stringent quality regulations. This underscores the indispensable role of CCFs in fostering operational excellence and driving competitive advantage.

A comprehensive checking fixture plays a critical role in quality assurance, serving as a vital tool for manufacturers to ensure that products meet specified tolerances and design requirements. According to a report by the Quality Assurance Institute, approximately 20% of manufacturing defects stem from measurement errors. By utilizing a checking fixture, companies can minimize these errors through precise measurement and verification processes, ultimately leading to a reduction in production costs and improved product reliability.

In addition to error reduction, comprehensive checking fixtures support the efficient implementation of quality control protocols. The National Institute of Standards and Technology (NIST) has noted that firms using specialized checking fixtures can achieve a 30% increase in inspection efficiency, allowing for faster turnaround times without compromising on quality. These fixtures not only help in maintaining consistency across batches but also facilitate the identification of potential design issues early in the production process, thereby enhancing overall product quality and customer satisfaction. As industries continue to embrace automation and advanced manufacturing techniques, the importance of robust checking fixtures in safeguarding quality standards cannot be overstated.

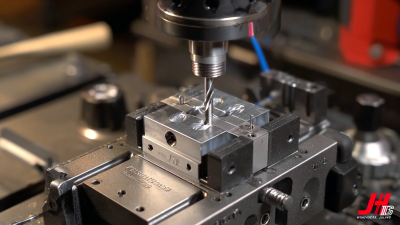

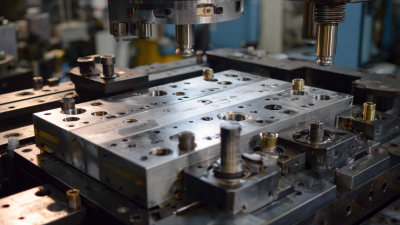

When designing a comprehensive checking fixture for quality assurance, several key components must be considered to ensure its effectiveness. Firstly, the fixture's material must be chosen carefully to withstand the forces applied during inspection while maintaining precise dimensions. Rigid materials are often required for stability, particularly when dealing with thin-walled components that are vulnerable to deformation. This stability is crucial in applications such as milling, where even slight changes in geometry can lead to significant quality issues.

Furthermore, the design should incorporate modular elements to allow for flexibility and ease of adaptation to various parts. This enables manufacturers to quickly switch between different setups, enhancing productivity without compromising accuracy. Additionally, incorporating advanced technologies such as CAD-based modeling can streamline the creation and documentation of the fixture. As manufacturers face evolving challenges, such as those presented by complex geometries and demanding material properties, intelligent fixture design becomes essential in maintaining high standards of quality assurance throughout the production process.

When assembling an effective comprehensive checking fixture for quality assurance, the process begins with careful planning and design. First, you should define the specific measurements and tolerances required for the components you will be checking. This involves consulting engineering drawings and collaborating with relevant stakeholders to ensure all quality metrics are captured. Next, select materials that provide durability and stability to withstand repeated use. Ensure that the fixture can accommodate various components by incorporating adjustable features or modular designs.

Once the design phase is complete, the next step is to accurately fabricate the fixture. Utilize precision machining techniques to create the base and support structures, ensuring that all critical dimensions are adhered to. After assembly, implement a systematic approach for incorporating measuring devices such as dial indicators or laser sensors, strategically positioning them where they can effectively capture necessary data without interference. Finally, perform a series of validation checks to confirm that the fixture meets the required standards and functions as intended, making adjustments as needed to optimize performance.

Effective quality assurance relies heavily on rigorous testing and calibration techniques. To ensure that products meet specified standards, it is crucial to incorporate systematic testing procedures during the quality assurance process. This involves establishing a clear framework for conducting tests that simulate real-world conditions the product may face. Continuous monitoring and periodic evaluations during the manufacturing stage can help identify potential defects and deviations early. Utilizing statistical process control and reliability testing can further enhance the evaluation process, ensuring that the fixture remains aligned with quality expectations.

Calibration techniques are equally important in maintaining the accuracy and reliability of measuring equipment used in quality assurance. Regular calibration ensures that tools and instruments yield precise readings, which is vital for maintaining quality control standards. Implementing a scheduled calibration plan that takes into account the equipment's usage and potential wear is essential. Furthermore, leveraging advanced technology, such as automated calibration systems, can streamline the calibration process, reducing human error and increasing efficiency in quality assurance practices. By integrating these testing and calibration techniques, organizations can foster a robust quality assurance framework that significantly elevates product quality and customer satisfaction.

Maintaining and upgrading a checking fixture is essential for ensuring its continued efficacy in quality assurance processes. Regular inspections should be conducted to identify wear and tear, misalignments, or any deviations that may compromise accuracy. Implementing a routine maintenance schedule not only prolongs the fixture's lifespan but also ensures that it consistently meets production quality standards. Keeping a detailed log of inspections and maintenance activities can help track performance trends and inform future upgrades.

Upgrading your checking fixture should be based on feedback from operators and any advancements in technology. Incorporating digital measuring tools and sensors can enhance precision and reduce human error. Additionally, ensuring that the fixture is versatile enough to accommodate different products is crucial as production lines evolve. Training personnel on new features and ensuring they are familiar with the upgraded technology can lead to significant improvements in overall productivity and quality assurance effectiveness. By prioritizing both maintenance and strategic upgrades, organizations can maximize the utility of their checking fixtures and maintain high standards in quality control.

This chart illustrates the quality assurance ratings achieved during various phases of a project, including pre-production, production, post-production, maintenance, and upgrading. The ratings provide insight into effectiveness and areas for improvement in the quality assurance process.