Aerospace fixtures play a crucial role in aircraft manufacturing. These specialized tools and devices ensure precision during the assembly process. Without them, maintaining high-quality standards would be a challenge.

The design and functionality of aerospace fixtures can significantly impact production efficiency. For instance, they help streamline workflows and reduce errors. However, improper fixture usage can lead to delays and increased costs. This highlights the importance of training.

Moreover, the development of aerospace fixtures requires constant innovation. Manufacturers must adapt to new technologies and materials. As the industry evolves, so do the challenges. Reflecting on these practices can lead to better solutions and improved outcomes.

Aerospace fixtures are essential tools in aircraft manufacturing. They ensure precision and accuracy during assembly processes. Defined as specialized jigs and tools, aerospace fixtures hold components in place. This helps achieve the tight tolerances required in aviation standards. According to a recent industry report, up to 25% of manufacturing costs stem from assembly flaws. Proper fixtures can significantly reduce this risk.

The use of advanced materials in aerospace fixtures is now becoming common. Fiber-reinforced composites are lightweight yet durable. These materials can improve efficiency in the factory, yet they also pose challenges. They may require special training for handling and setup. If these issues are overlooked, production delays may occur.

Moreover, fixture designs must evolve with changing technologies. Automation is reshaping the manufacturing landscape. Robotics may require more adaptive and flexible fixtures to fit new processes. Errors in adapting can lead to costly mistakes, emphasizing the need for continual assessment. Investing in innovative designs could address these challenges, leading to enhanced operational stability in aircraft manufacturing.

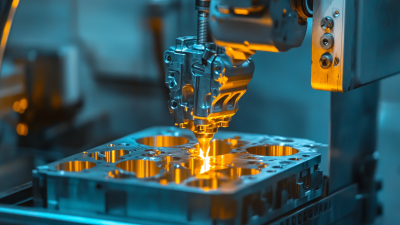

Aerospace fixtures play a crucial role in the aircraft production process. They provide a stable platform for assembling various components. These fixtures ensure precision and uniformity in manufacturing. Each part of an aircraft must fit together perfectly. This is where fixtures come in handy. They guide the machinists, ensuring every detail meets strict specifications.

However, creating effective aerospace fixtures is a complex challenge. Designers must consider the unique shapes of different parts. A fixture that works for one section may not fit another. This leads to trial and error. It can be frustrating and time-consuming. Also, even minor deviations can lead to significant issues down the line. It’s essential for engineers to continuously evaluate and improve fixture designs.

Moreover, the manufacturing world is rapidly changing. New materials and techniques are constantly emerging. This creates a demand for adaptable and innovative fixtures. Manufacturers need to be open to exploring new solutions. The journey of redesigning fixtures often reveals underlying issues. It encourages a culture of reflection and improvement within teams.

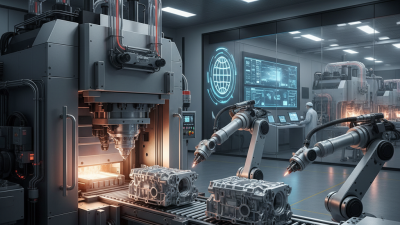

Aerospace fixtures play a crucial role in aircraft manufacturing. They ensure precision and efficiency during the assembly process. There are various types of aerospace fixtures, each designed for specific tasks. Common types include assembly fixtures, welding fixtures, and inspection fixtures. Each type serves unique purposes but collectively enhances production efficacy.

Assembly fixtures secure components during installation. They reduce the risk of errors. For instance, a report by a leading industry group revealed that implementing robust assembly fixtures can decrease assembly time by up to 30%. Welding fixtures, on the other hand, hold parts in place during welding. This method improves weld quality and consistency. Inaccurate positioning often leads to costly rework, making these fixtures essential.

Inspection fixtures are vital for quality control. They help ensure that every part meets stringent aerospace standards. Challenges remain, though. Finding the right fixture design can be complex. The industry often faces issues like high costs and long lead times for custom fixtures. Balancing quality and efficiency continues to be a work in progress.

Aerospace fixtures play a crucial role in aircraft manufacturing. They provide a stable platform for components during production. This stability leads to improved precision and consistency. According to a report by the Aerospace Industries Association, using advanced fixtures can increase production efficiency by 20%. However, the initial investment in these systems can be high.

Implementing aerospace fixtures reduces waste, as they minimize errors during assembly. This efficiency is vital in a competitive market. A study indicated that companies adopting these fixtures saw a reduction in production cycle time by up to 15%. Yet, some manufacturers still struggle to update their machinery and training for staff.

Training staff on new fixtures remains a challenge. Employees may resist change or lack the skills needed. Even small adjustments in fixture design can impact the overall manufacturing process. Finding the right balance between technology and human factors is essential. While fixtures enhance production, they also require careful planning and constant evaluation.

| Dimension | Description | Impact on Production Efficiency |

|---|---|---|

| Precision | Ensures exact placement and alignment of aircraft components. | Reduces rework and assembly errors, leading to increased efficiency. |

| Weight Savings | Utilizes lightweight materials for fixtures without sacrificing strength. | Contributes to overall aircraft weight reduction, improving fuel efficiency. |

| Modularity | Allows for quick changes in production lines with interchangeable parts. | Enhances adaptability and reduces downtime during production changes. |

| Automation | Incorporates automated systems for handling and positioning components. | Speeds up processes and minimizes the need for manual labor. |

| Cost Efficiency | Reduces production costs through optimized design and procurement. | Increases profit margins by lowering the overall manufacturing expenses. |

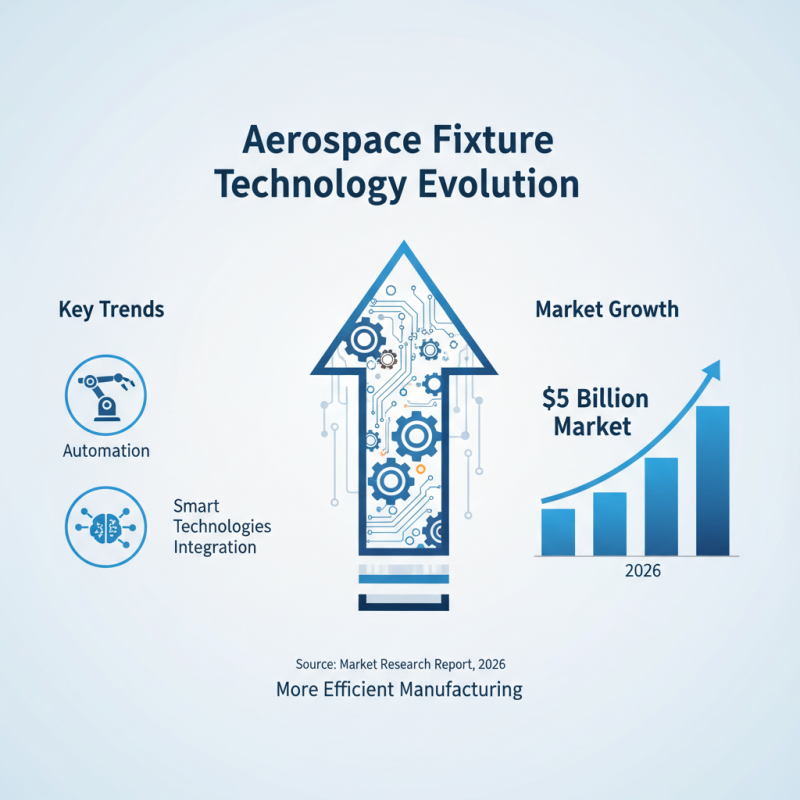

The aerospace industry is evolving rapidly. Advances in fixture technology are crucial. Currently, a significant focus is on automation and the integration of smart technologies. According to a recent market research report, the aerospace fixtures market is expected to reach $5 billion by 2026. This growth implies a shift towards more efficient manufacturing methods.

Innovations, such as lightweight materials, improve fixture design and performance. The use of materials like carbon fiber can reduce weight by up to 30%. However, the transition to these newer materials presents challenges. Existing manufacturing processes may need reevaluation. There are concerns about the cost implications of adopting cutting-edge technologies.

Furthermore, industry experts note the importance of sustainable practices. Many fixtures are still made using traditional methods that are not environmentally friendly. A balance must be found between innovation and sustainability. To remain competitive, manufacturers will need to rethink their approach, fostering a culture of continuous improvement while embracing necessary changes.