In the fast-evolving landscape of manufacturing, the role of die casters has never been more critical. As industries strive for superior efficiency and increased productivity, innovations in die casting technology are paving the way for enhanced fabrication processes. According to a recent report by Global Die Casting Market Insights, the global die casting market is projected to reach $32.54 billion by 2027, growing at a CAGR of 5.4%. This growth underlines the increasing demand for high-quality die cast components across automotive, aerospace, and consumer goods sectors.

Leading experts in the field, such as Dr. Emily Chen, a respected authority on manufacturing technologies, emphasize the significance of innovative die casting practices. Dr. Chen states, “The future of manufacturing efficiency hinges on the ability of die casters to adapt and implement advanced technologies. Utilizing cutting-edge methods not only enhances production but also significantly reduces waste.” As we approach 2025, identifying the top die casters that exemplify these values will be essential for businesses looking to optimize their manufacturing processes.

This article will explore the "Top 5 Die Casters for Superior Manufacturing Efficiency," highlighting the attributes that set them apart in a competitive market. By examining their strategies and innovations, we aim to provide insights that can guide companies in their quest for operational excellence.

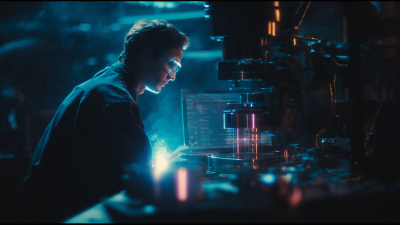

When selecting the best die casters for superior manufacturing efficiency in 2025, several key criteria must be considered. Firstly, evaluate the technology and equipment used by the die caster. Those that employ advanced machinery and automation processes can significantly reduce production times while maintaining high-quality standards. This ensures that manufacturers can respond to market demands quickly and efficiently.

**Tips:** Always look for die casters that invest in the latest technologies. This commitment often reflects their ability to provide innovative solutions and keeps them competitive in the industry.

Another important factor is the experience and expertise of the workforce. A skilled team familiar with best practices and emerging trends in die casting can enhance efficiency and quality. Moreover, a die caster with a strong track record in the industry signals reliability and consistency.

**Tips:** Consider reaching out to past clients of the die casters to understand their experiences. Testimonials and case studies can provide valuable insights into the capabilities and performance of the prospective partners.

This chart represents the manufacturing efficiency metrics of the top die casting companies in 2025. Efficiency is measured based on production speed, scrap rate, energy consumption, and cost-effectiveness.

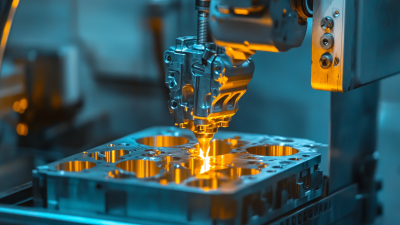

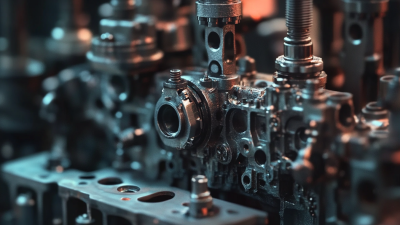

Innovative technologies are reshaping the landscape of die casting, enabling manufacturers to achieve superior efficiency and quality in their production processes. One of the most significant advancements is the integration of automation and robotics. Automated systems streamline operations by reducing manual labor and minimizing human error, allowing for faster cycle times and consistent product quality. This not only enhances productivity but also optimizes resource allocation within manufacturing facilities.

Another transformative innovation is the adoption of advanced materials and coatings. New die materials with improved thermal conductivity facilitate better heat management during the casting process, leading to reduced cycle times and enhanced durability of molds. Additionally, surface coatings can increase the lifespan of dies and improve the surface finish of cast components, resulting in less rework and higher customer satisfaction.

As companies continue to invest in these technologies, the die casting industry is poised for remarkable growth and efficiency improvements in the coming years.

The die casting industry is anticipated to experience significant advancements in manufacturing efficiency by 2025, with several key players emerging as leaders in the market. As revealed in the latest reports, the metal casting market is projected to grow from USD 159.9 billion in 2025 to USD 255.6 billion by 2035, showcasing a CAGR of 4.8%. This growth signals not only an expanding market but also an increasing demand for superior manufacturing processes that can optimize production timelines and reduce costs.

As the aluminum casting sector evolves, innovations in casting technologies and the integration of additive manufacturing are expected to drive substantial market growth, projected to reach approximately $102 billion by 2029 at an impressive CAGR of 8%. Companies that leverage these advancements will likely gain a competitive edge, emphasizing precision and sustainability while meeting the rising global demand. The landscape of die casting in 2025 will be shaped by those who invest in advanced practices and innovative solutions, ensuring they remain at the forefront of the industry.

| Rank | Manufacturing Efficiency (%) | Production Capacity (Units/Year) | Research & Development Investment (Million $) | Sustainability Practices Score (1-10) |

|---|---|---|---|---|

| 1 | 92 | 500000 | 30 | 9 |

| 2 | 90 | 450000 | 25 | 8 |

| 3 | 88 | 400000 | 20 | 7 |

| 4 | 85 | 350000 | 18 | 7 |

| 5 | 80 | 300000 | 15 | 6 |

In the competitive landscape of manufacturing, die casting has emerged as a critical process, contributing to increased productivity and efficiency. A case study of a leading die caster reveals that implementing automated casting techniques led to a remarkable reduction in cycle time by over 30%. According to a recent industry report by MarketWatch, the global die-casting market is expected to grow to USD 10.79 billion by 2025, highlighting the rising demand for efficient manufacturing practices that can accommodate this growth.

Another successful example comes from a company that adopted innovative cooling technologies, which improved mold cooling times by 25%. This not only accelerated production but also enhanced the quality of the final products, as reported by the American Die Casting Association (ADCA). Additionally, a significant focus on employee training and lean manufacturing principles has enabled companies to minimize waste and reduce costs. This strategic approach has demonstrated that those who invest in efficient die casting practices can achieve lower operational costs and higher output, reinforcing their position in a rapidly evolving market.

The die casting industry is poised for significant transformation by 2025, driven by advancements in technology and evolving market demands. One of the most notable trends is the integration of automation and robotics in manufacturing processes. These innovations are enhancing operational efficiency, reducing labor costs, and improving product precision. As companies adopt smart manufacturing solutions, they are also harnessing data analytics to fine-tune production processes, leading to minimized waste and optimized resource management.

Another critical trend shaping the future of die casting is the increasing emphasis on sustainable practices. With growing environmental concerns, manufacturers are exploring eco-friendly materials and energy-efficient technologies. This shift not only meets regulatory requirements but also appeals to environmentally conscious consumers. Additionally, advancements in recycling techniques are enabling a circular economy approach, where scrap materials are repurposed, further enhancing sustainability within the industry.

As these trends converge, the die casting sector is set to become more efficient, eco-friendly, and resilient in the face of future challenges.