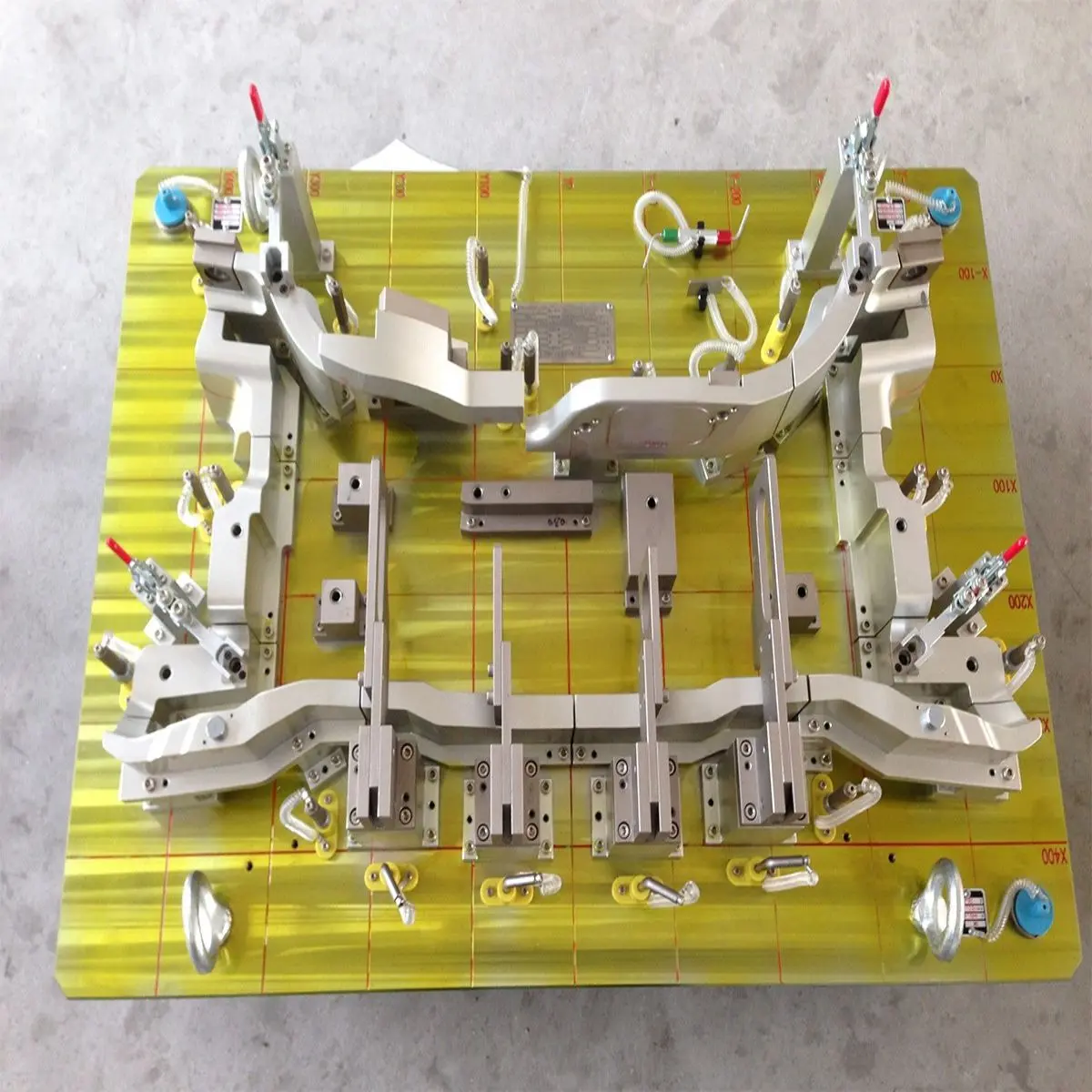

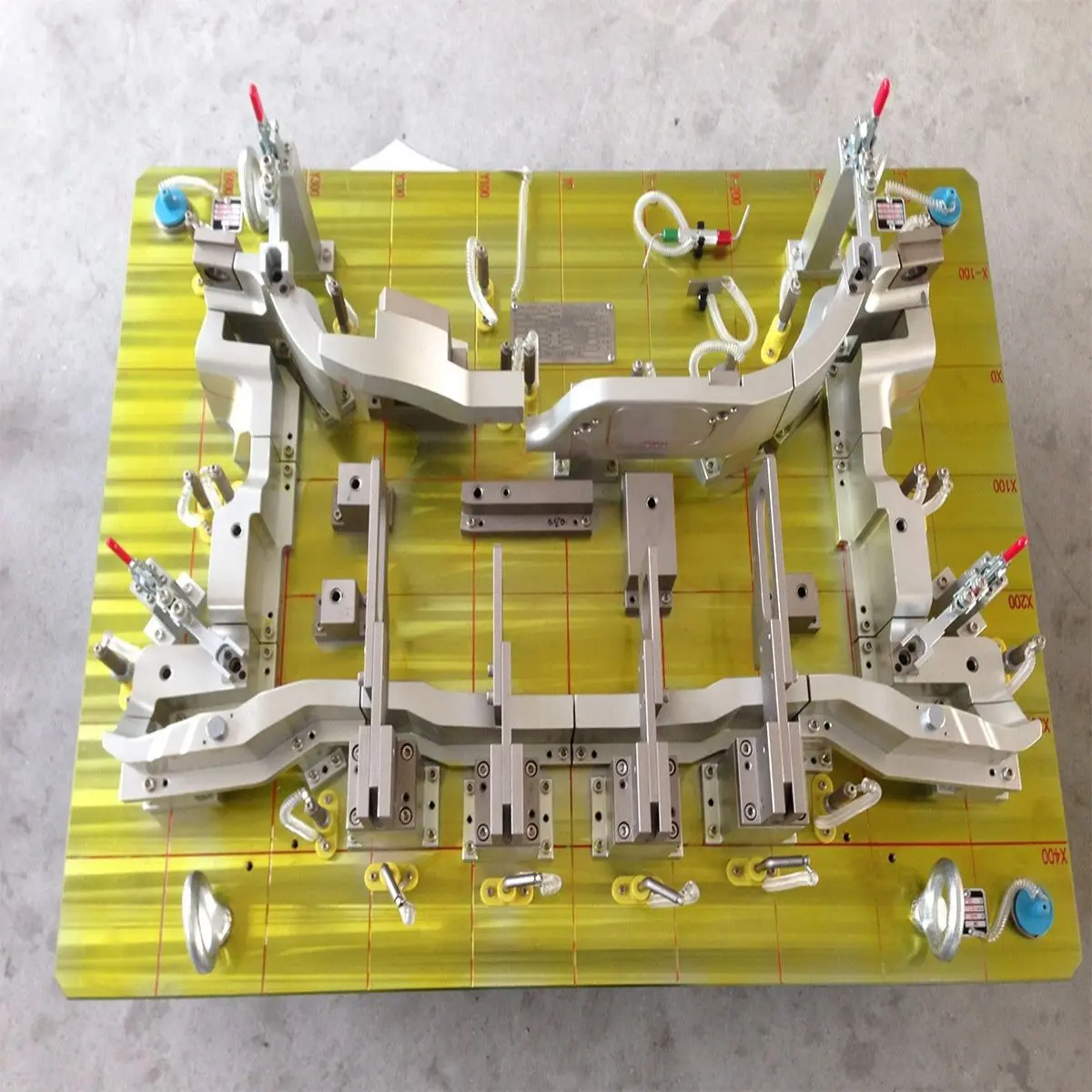

Product Description

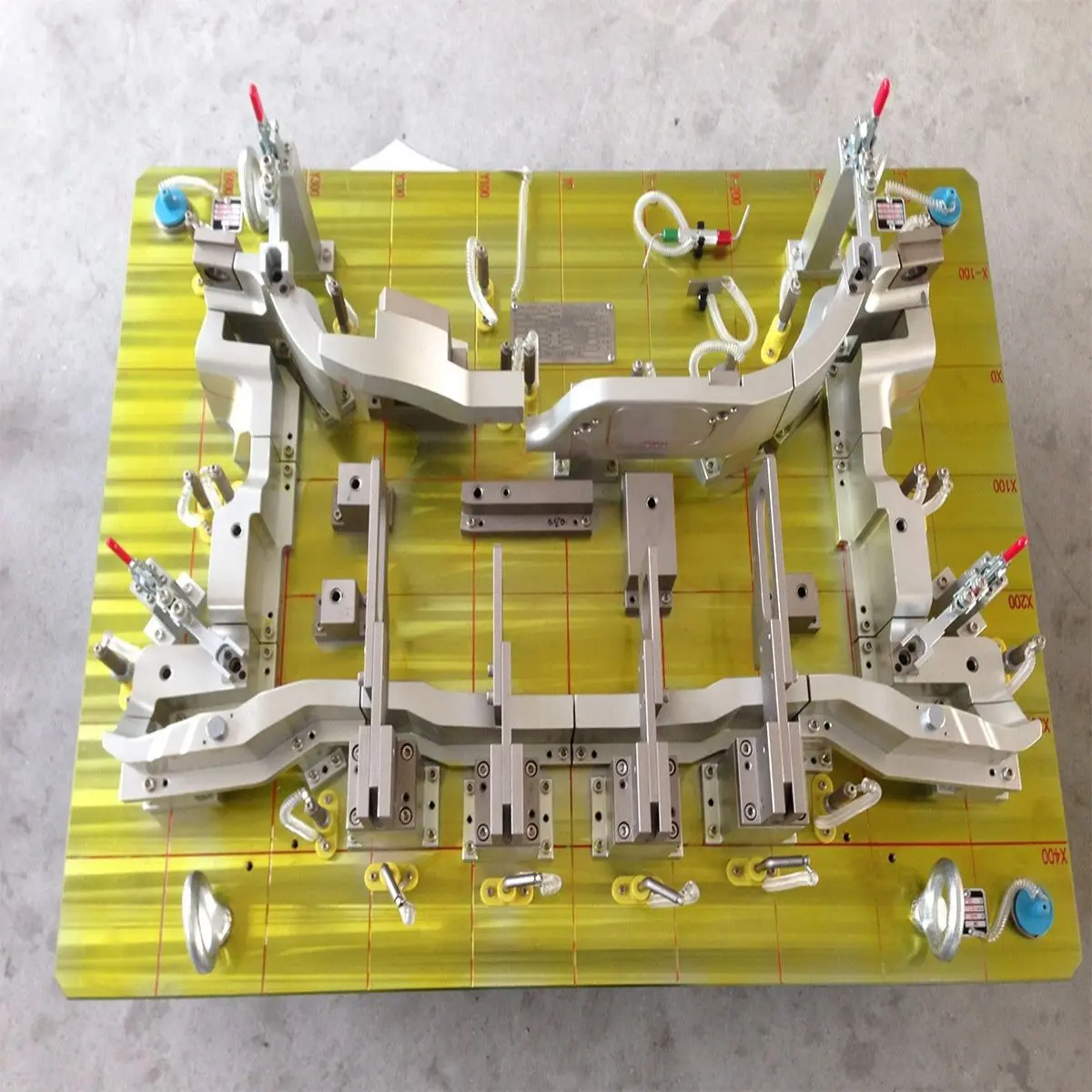

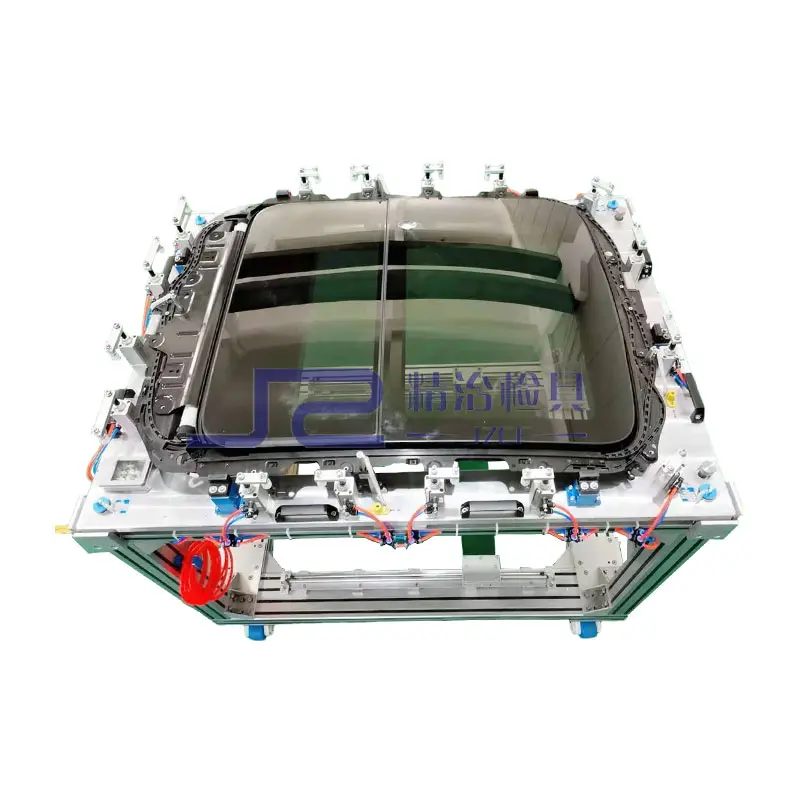

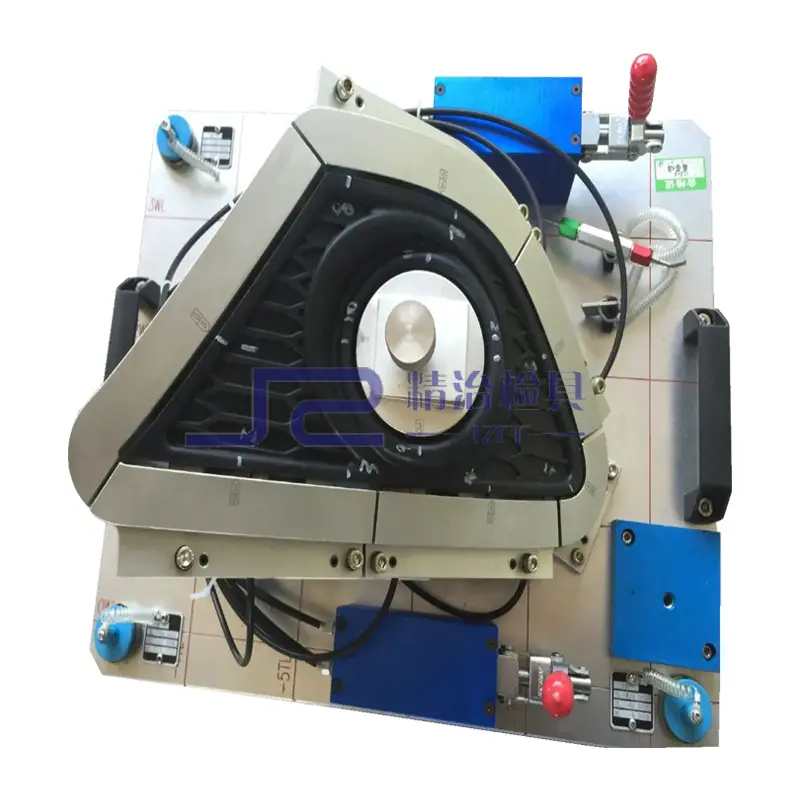

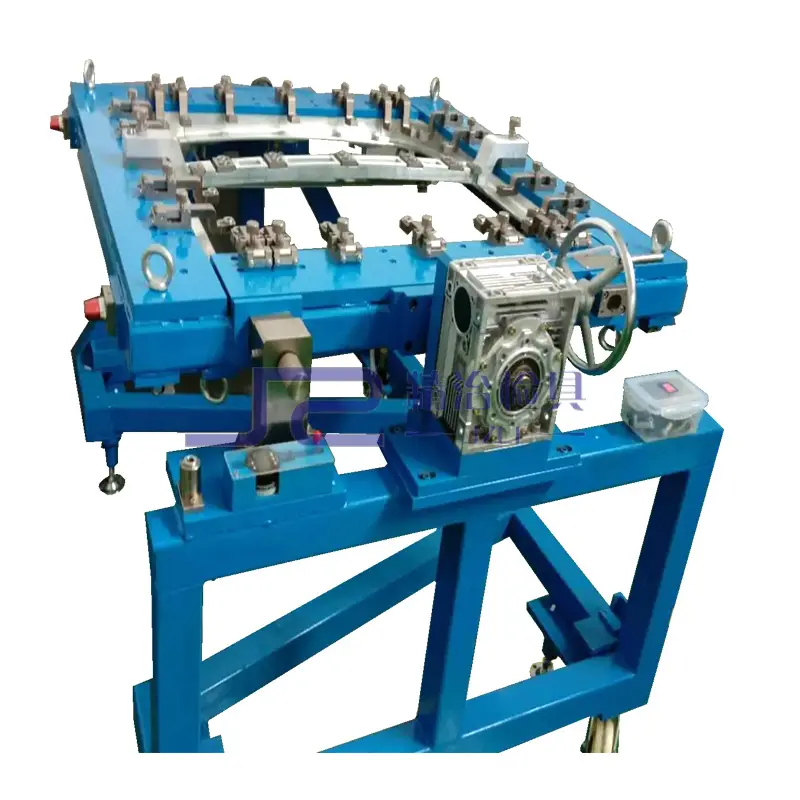

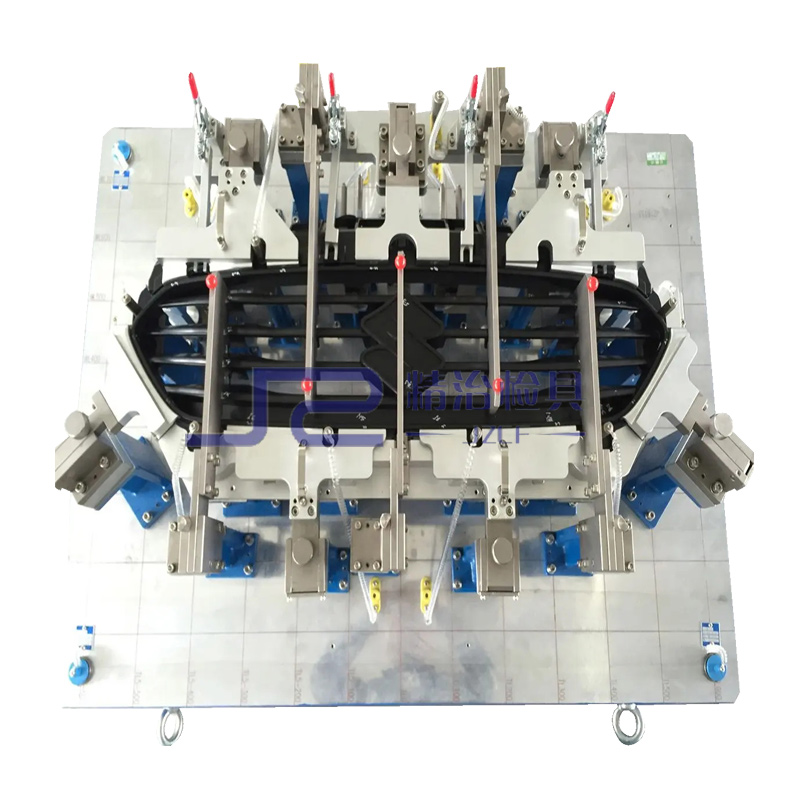

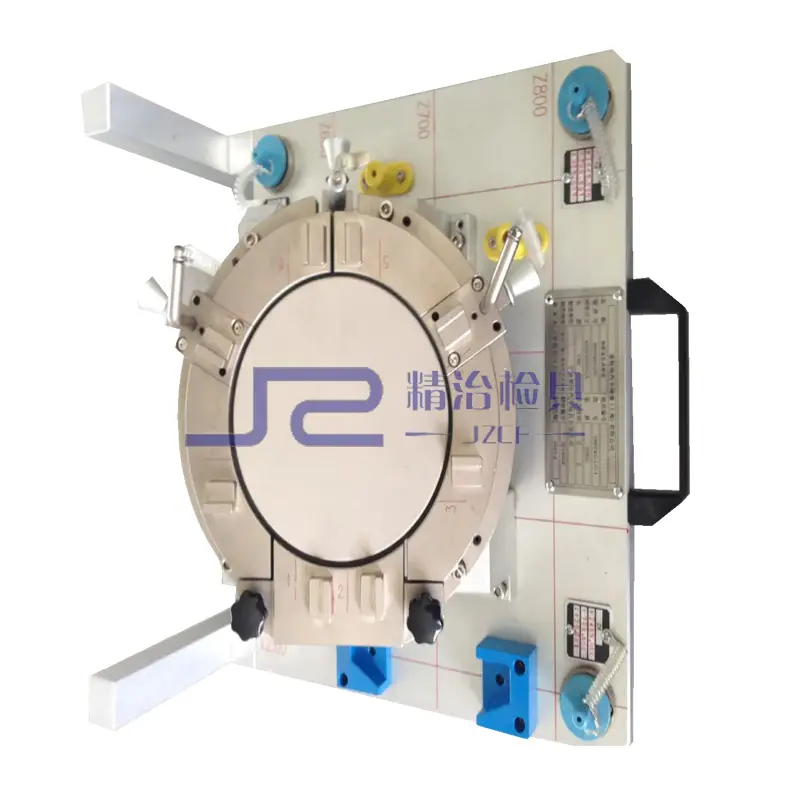

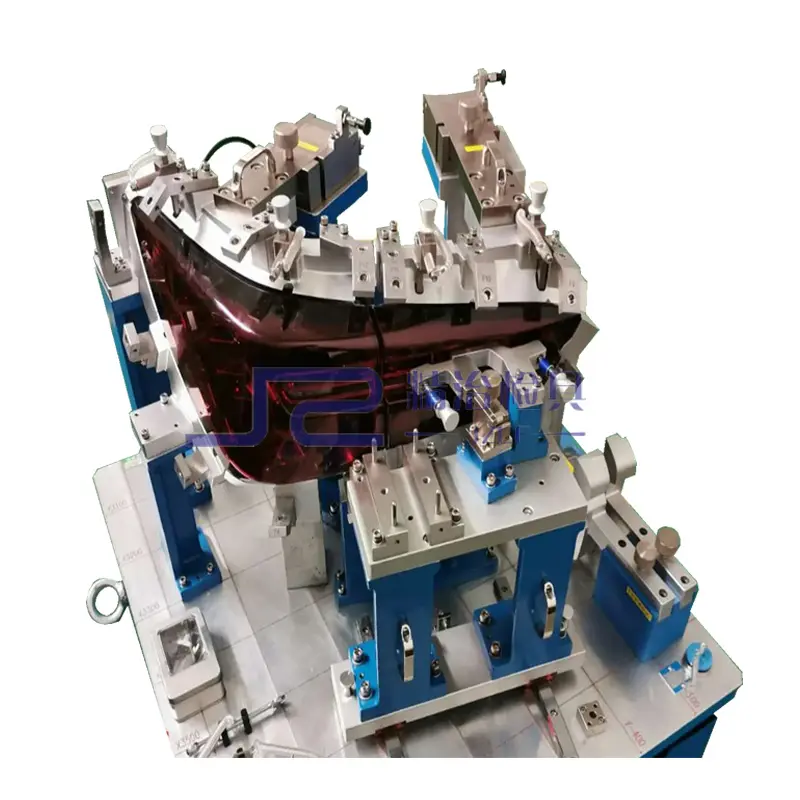

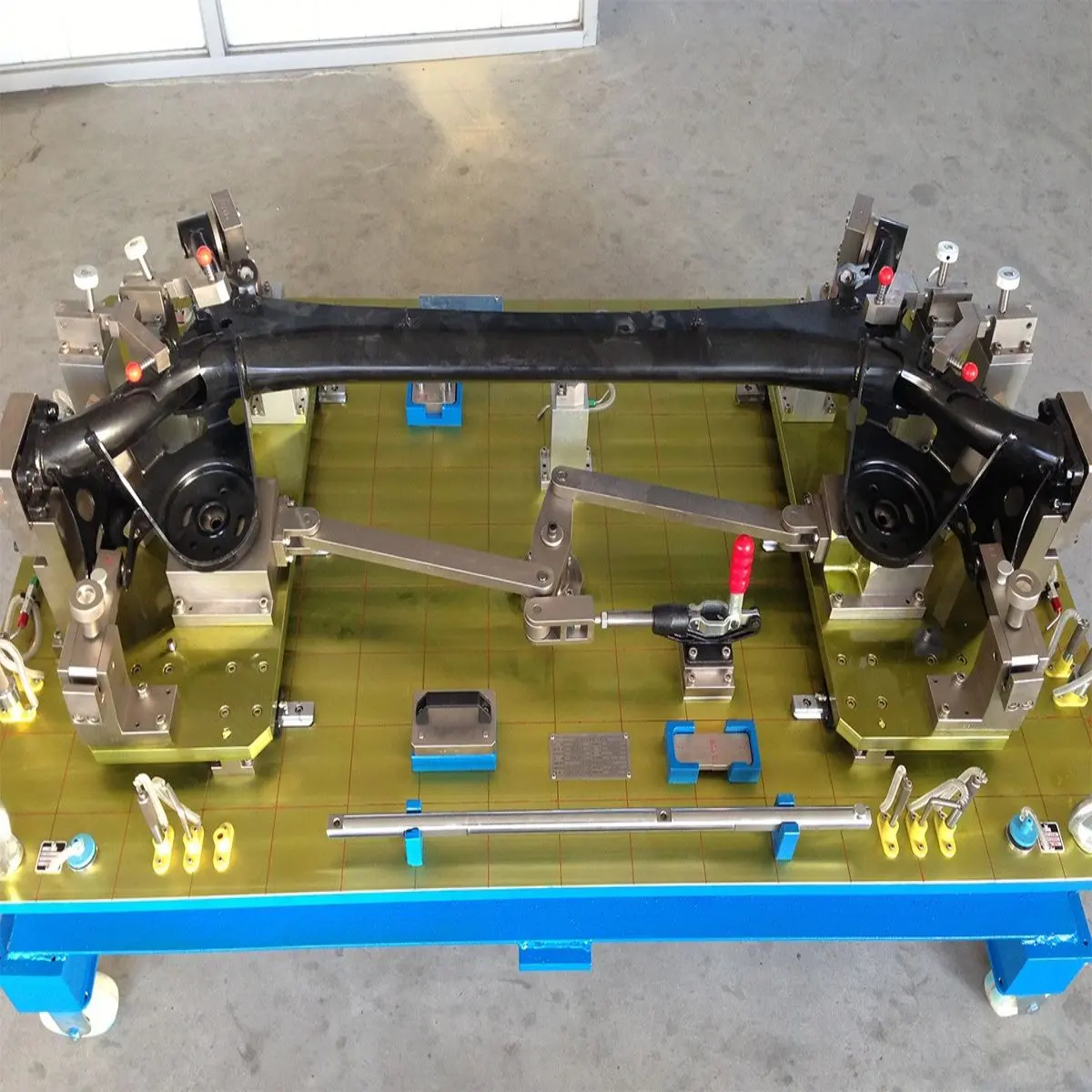

The advantages of using a secondary framework are many. First, it improves safety during maintenance operations. By providing stable support, the auxiliary frame reduces the risk of accidents and ensures maintenance personnel can perform their tasks with confidence and peace of mind.checking fixture has high measurement accuracy, no fear of deformation, low maintenance cost and good convenience. Key product characteristic inspection, characteristic line inspection, function hole inspection, area detection which is prone to deformation in assembly process, for automobile assembly and production function matching inspection. In the production process of automotive parts, on-line inspection of automotive parts is realized, which ensures the rapid judgment of the quality status of automotive parts in production, ensures the safety and processing speed of automotive assembly, and improves the quality of automotive parts.

Moreover, the use of auxiliary stands can significantly improve work efficiency. With the support and positioning provided by the frame, maintenance personnel can replace and repair chassis components more conveniently and easily. Not only does this save time and energy, but it also enables a more efficient workflow, ultimately increasing productivity.

Precise positioning is another major benefit of using a secondary frame. The frame helps adjust the position of the vehicle, ensuring chassis components are installed and adjusted with the utmost precision and accuracy. This is critical to maintaining the structural integrity of the vehicle and ensuring that all components are properly aligned.

In addition, the versatility of the auxiliary frame is a significant advantage. These frames are usually designed to be adjustable, making them suitable for use with different vehicle models. This broad applicability allows the subframe to meet the diverse maintenance needs of all types of vehicles, making it a valuable tool for automotive maintenance professionals.

The subframe is an indispensable tool in car maintenance. Its ability to provide stable support, improve safety, improve work efficiency, achieve precise positioning, and meet the diverse needs of different vehicle models makes it an important asset in the repair tool kit. By using this tool, maintenance personnel can ensure that their work is performed with the highest precision and efficiency, ultimately leading to better results and customer satisfaction. As the automotive industry continues to develop, the importance of subframes in automotive maintenance cannot be overstated. It is a tool that ensures the reliability and safety of vehicle maintenance operations, making it a valuable investment for any professional in the field.