0102030405

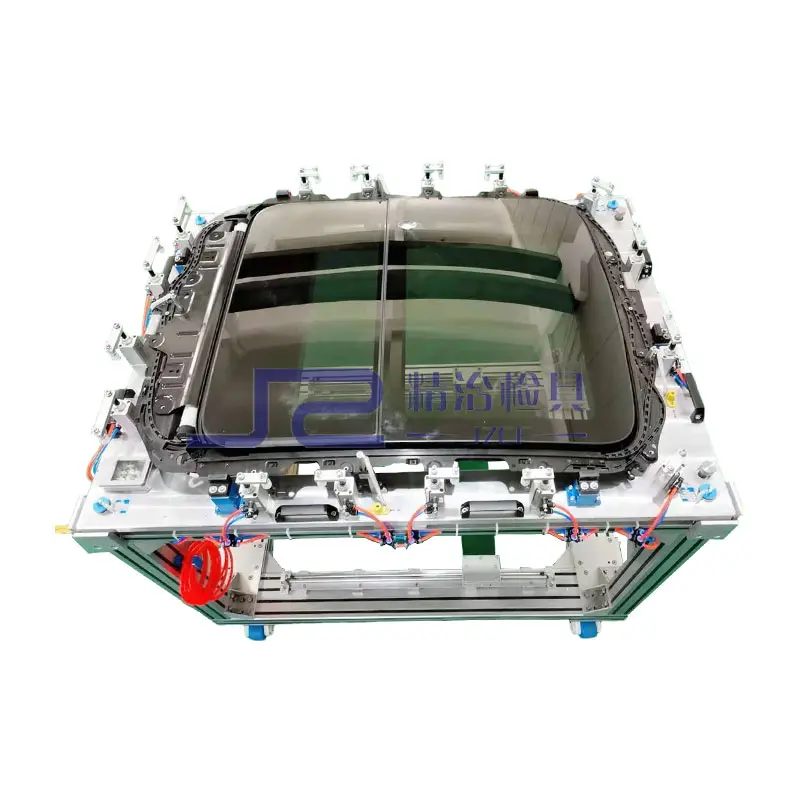

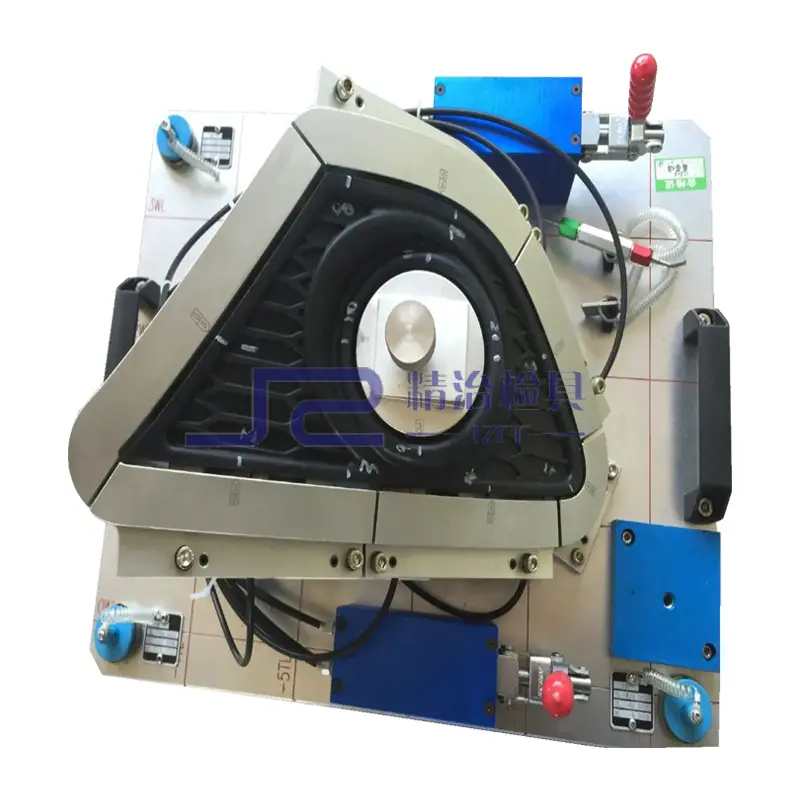

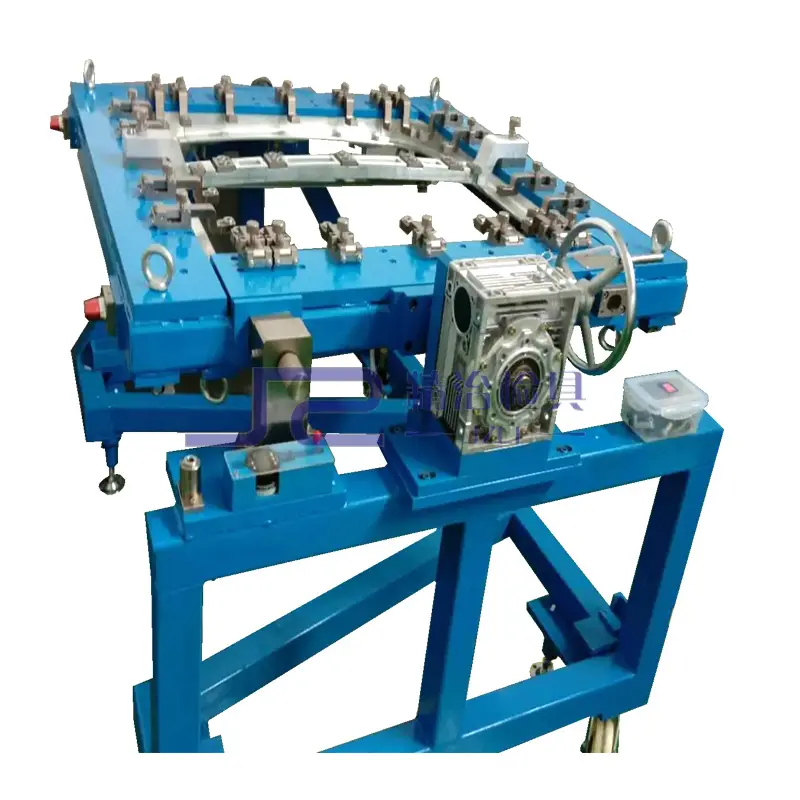

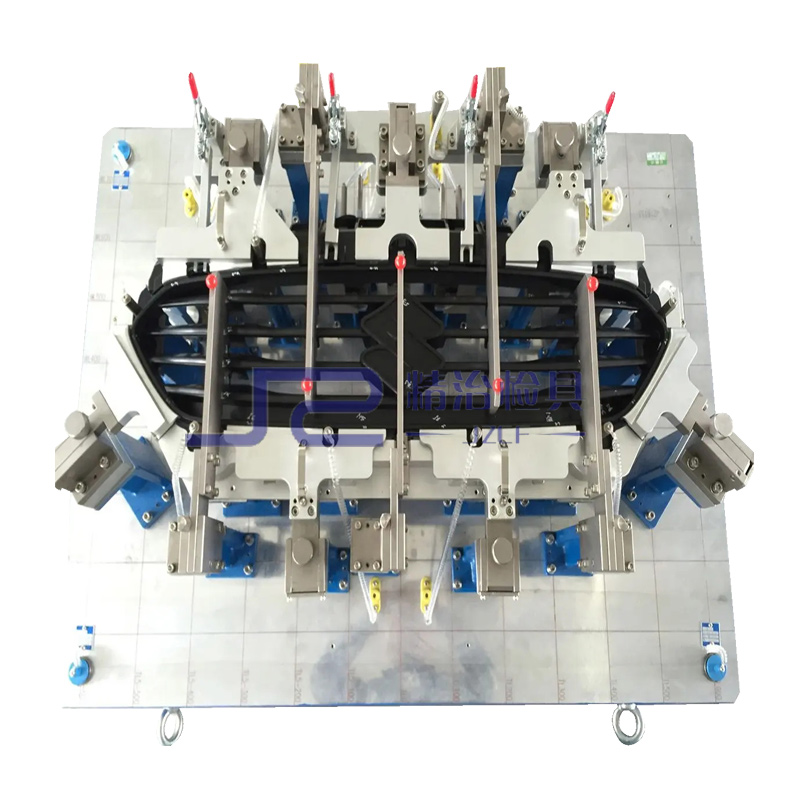

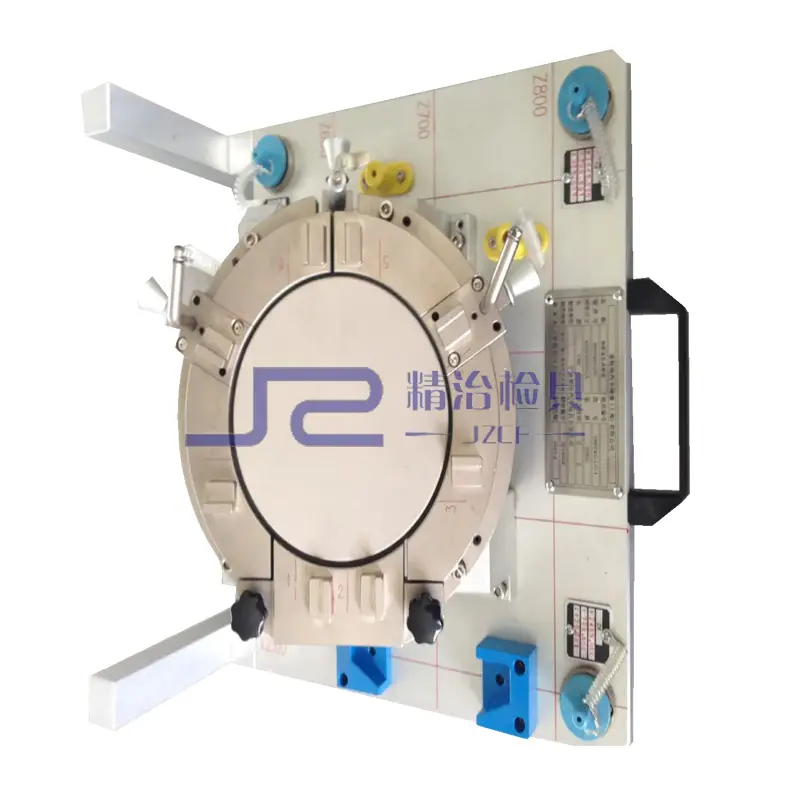

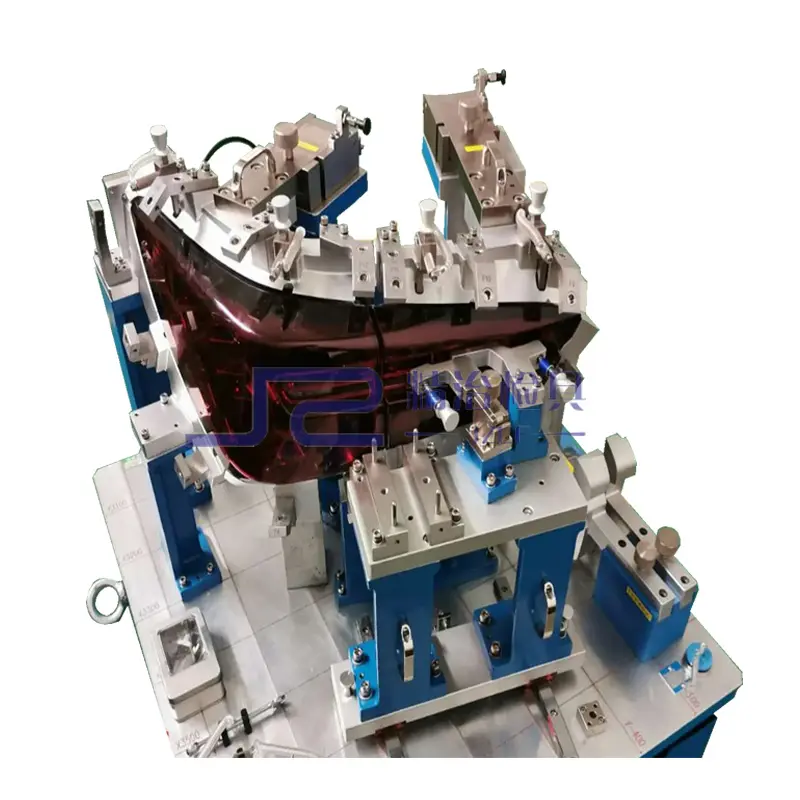

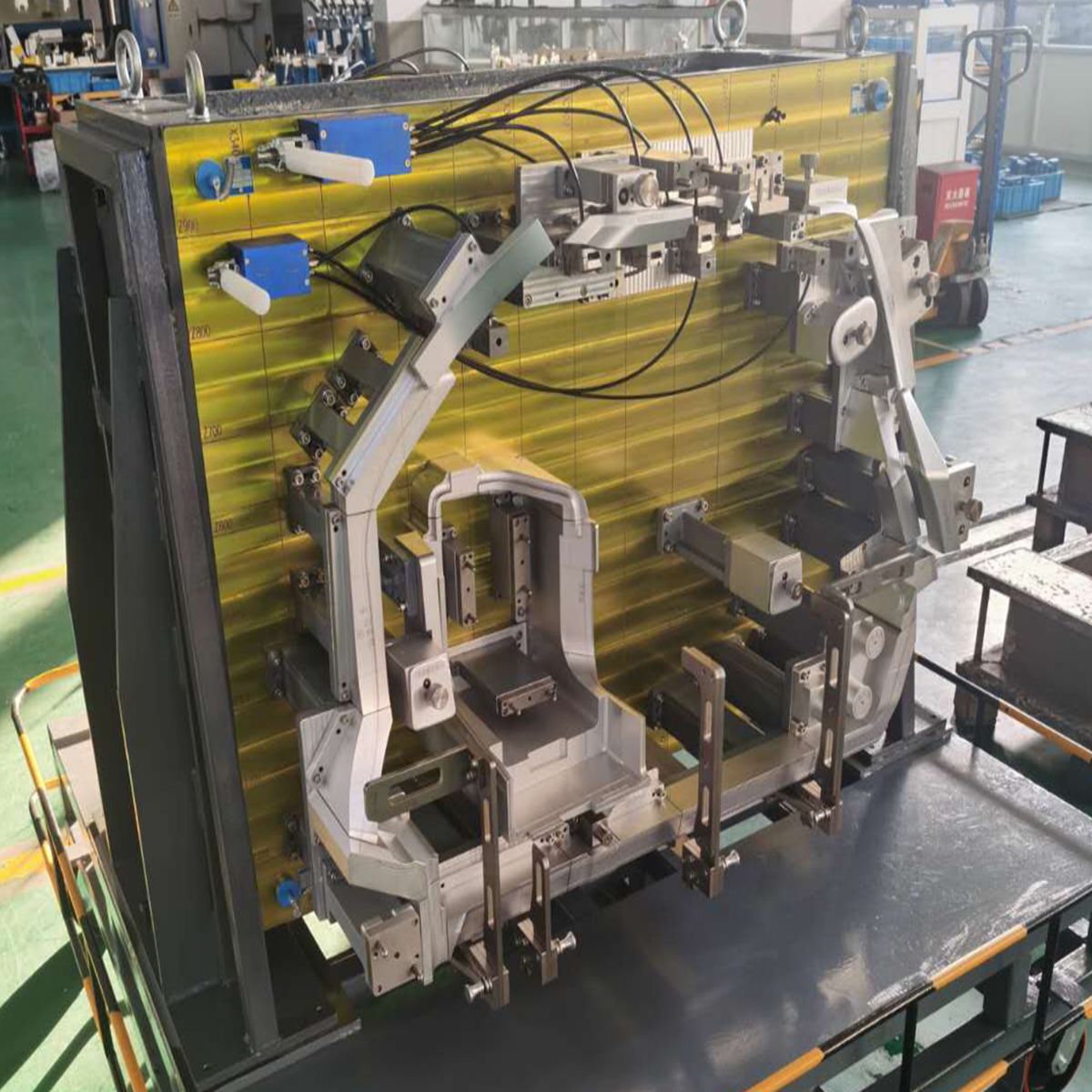

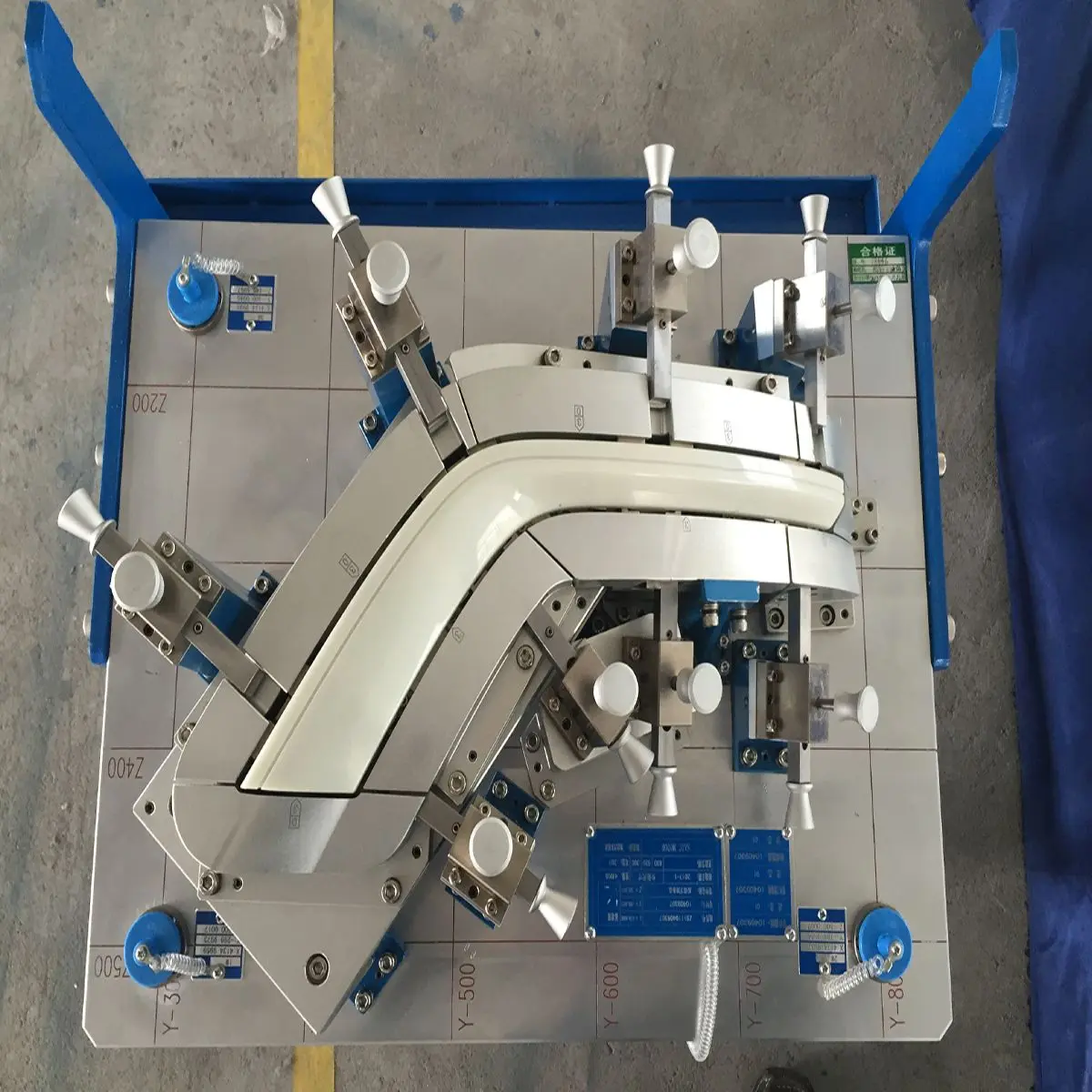

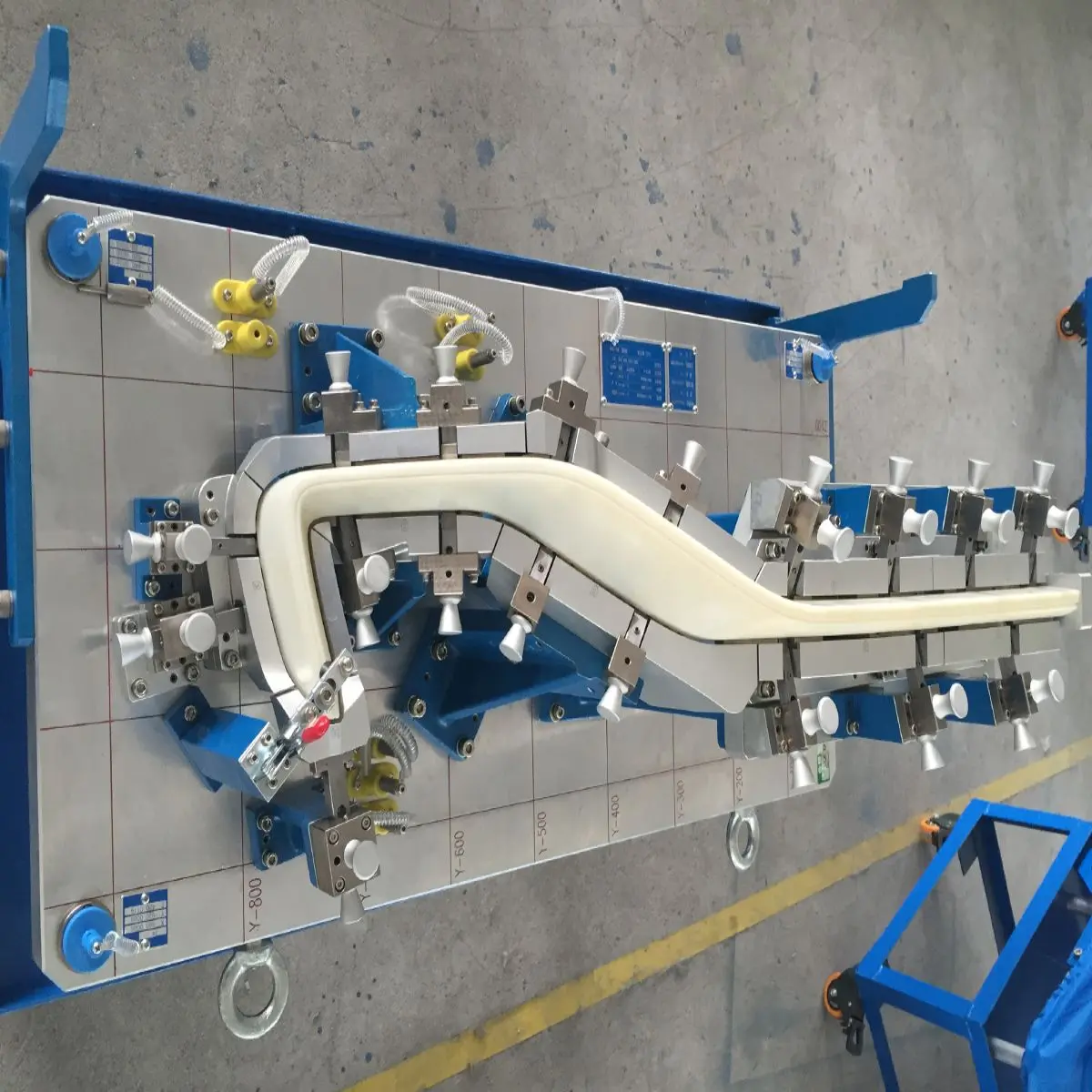

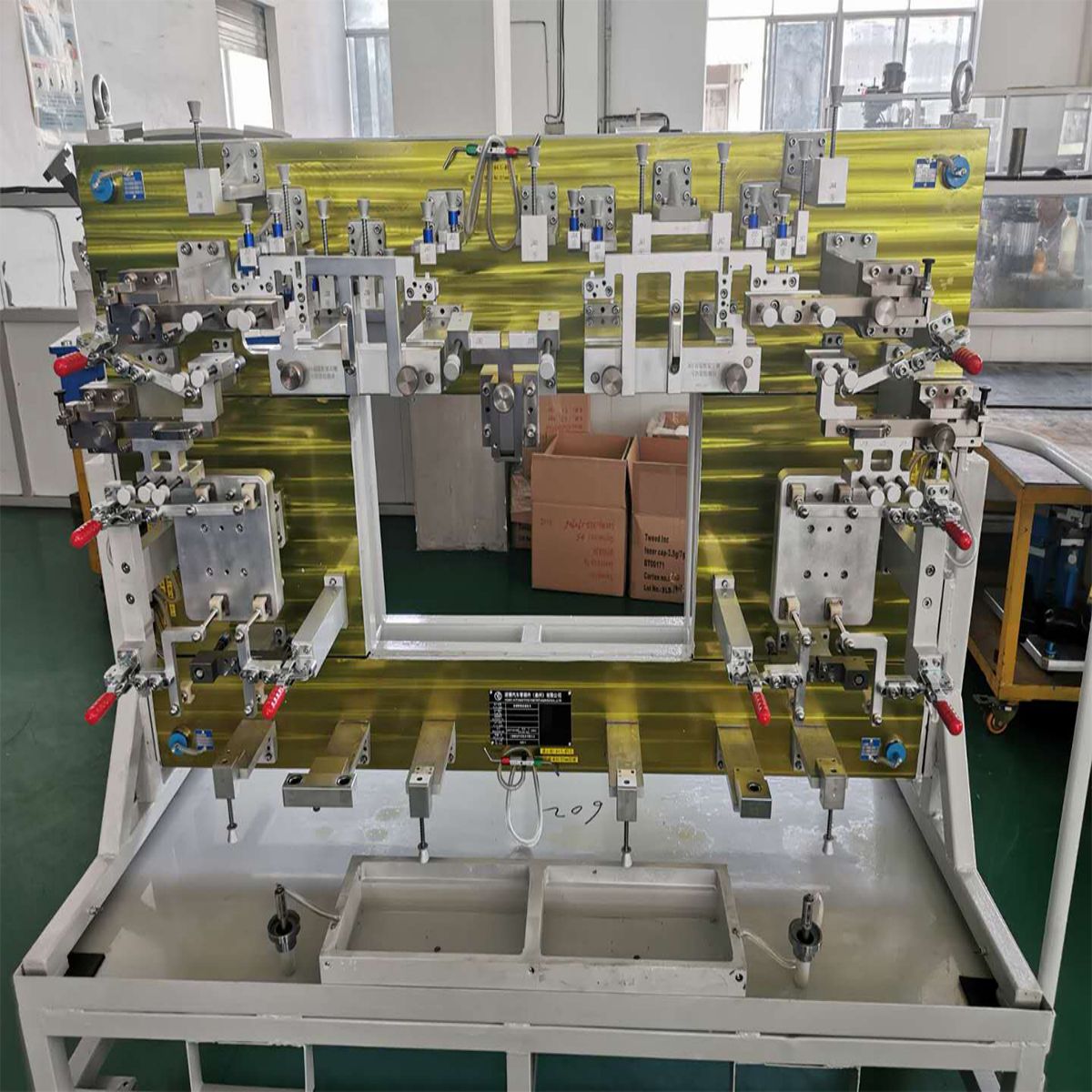

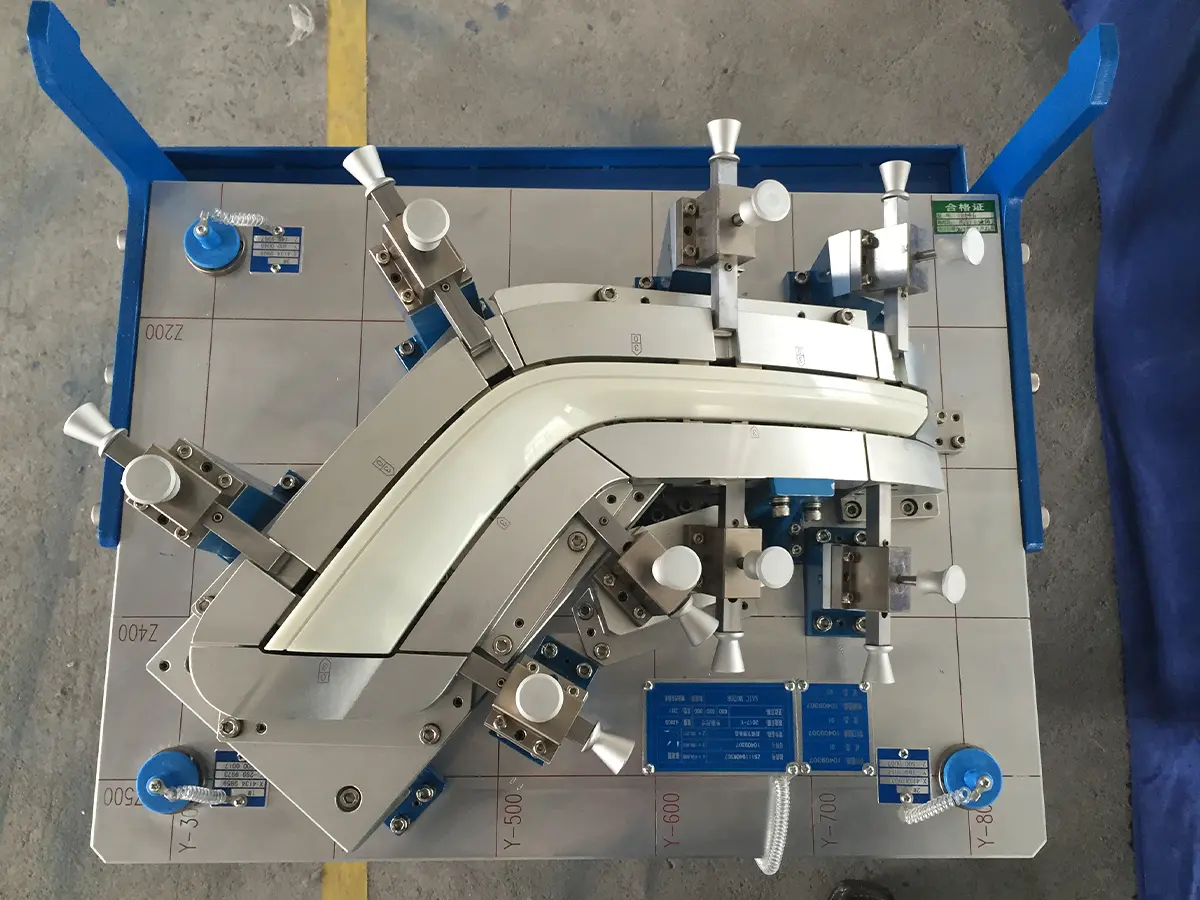

Checking fixture other inspection tools are used to inspect the quality of automobile parts

Product Description

In addition, these inspection tools also play a vital role in improving assembly efficiency. By using them, operators can position and assemble parts quickly and accurately, reducing assembly errors and improving overall assembly efficiency. This reduces production time and costs and reduces scrap rates, ultimately helping to make the manufacturing process more efficient.

In addition to improving quality and efficiency, the use of inspection tools also helps reduce costs. By ensuring parts are assembled correctly, these tools help minimize assembly errors and scrap, thereby increasing production efficiency and reducing scrap rates. This not only saves material costs, but also reduces the need for rework and repairs, further reducing production expenses.

The use of detection tools ensures the safety performance of the car. By verifying the proper installation and retention of automotive parts, these tools help reduce safety hazards that may arise from loose or misaligned parts. Ensuring that all components are installed and secured correctly is crucial to maintaining the safety and reliability of your vehicle, which is critical in the automotive industry.

Interior trim checking fixture has high measuring accuracy, not afraid of deformation, low maintenance cost and good convenience. Key product characteristic detection, characteristic line detection, function hole detection, deformation prone area detection during assembly, automobile assembly and production function matching detection. In the production process of auto parts, the realization of online inspection of auto parts ensures the rapid judgment of the quality of auto parts in the production, ensures the safety and processing speed of auto assembly, and improves the quality of auto parts.

Generally speaking, the use of automobile air conditioning housing assembly inspection tools, front-end frame inspection tools, and left and right inner panel inspection tools is crucial to improving the quality and efficiency of the automobile production and assembly process. These tools not only ensure the quality and performance of automotive parts but also help reduce costs and improve safety. As the automotive industry continues to evolve, the importance of these inspection tools in ensuring the overall quality and efficiency of automotive production cannot be overstated.

The use of automotive inspection tools is critical to maintaining high standards of quality, performance and safety in the automotive industry. By leveraging these tools, manufacturers can ensure parts meet design specifications, improve assembly efficiency, reduce costs and enhance the overall safety of the vehicle. Therefore, the use of inspection tools is an important aspect of the manufacturing process and plays an important role in shaping the future of the automotive industry.

description2