01020304

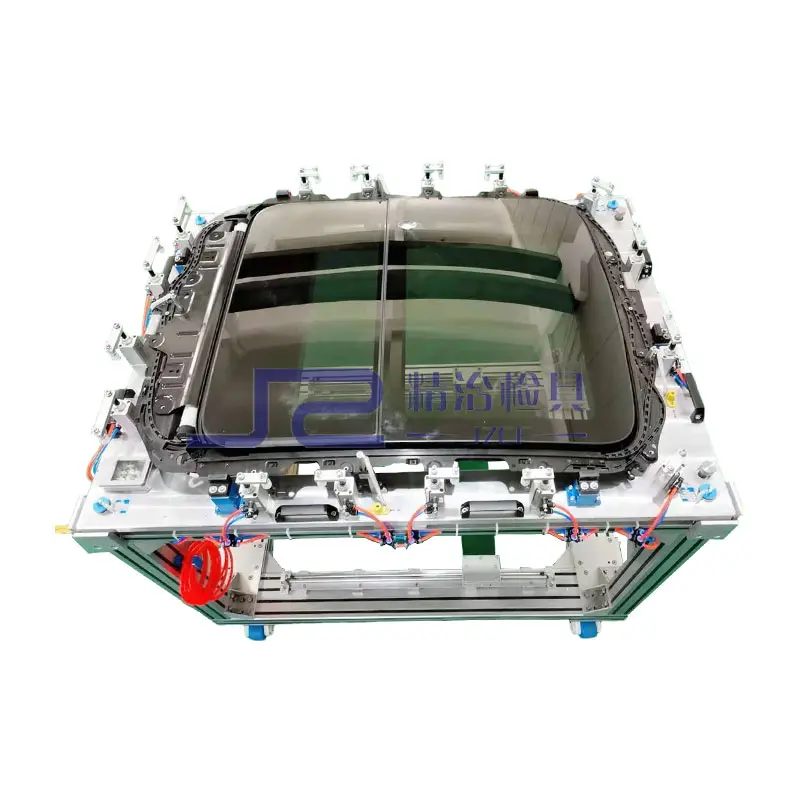

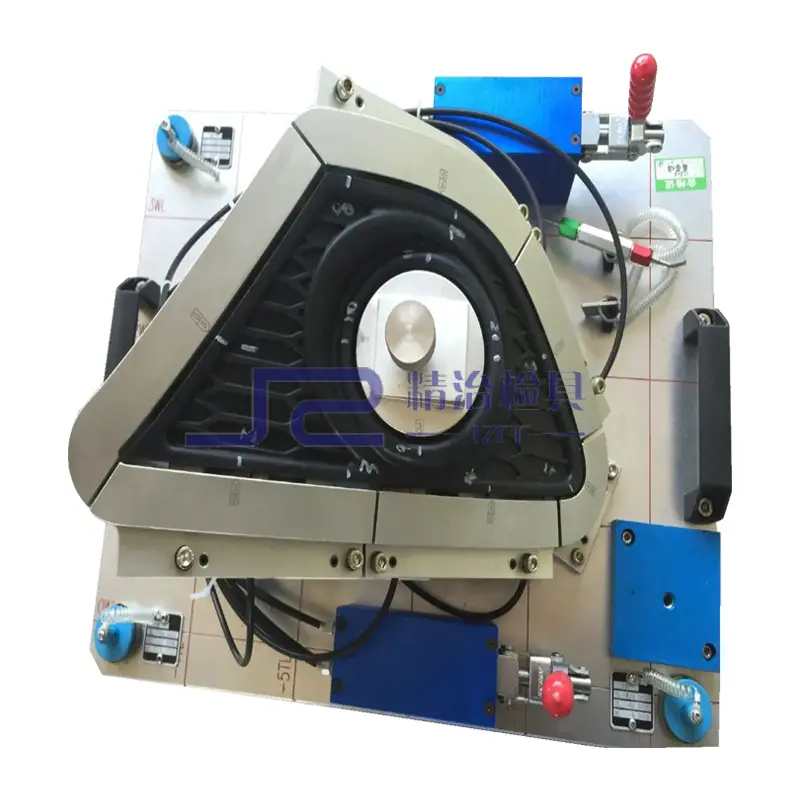

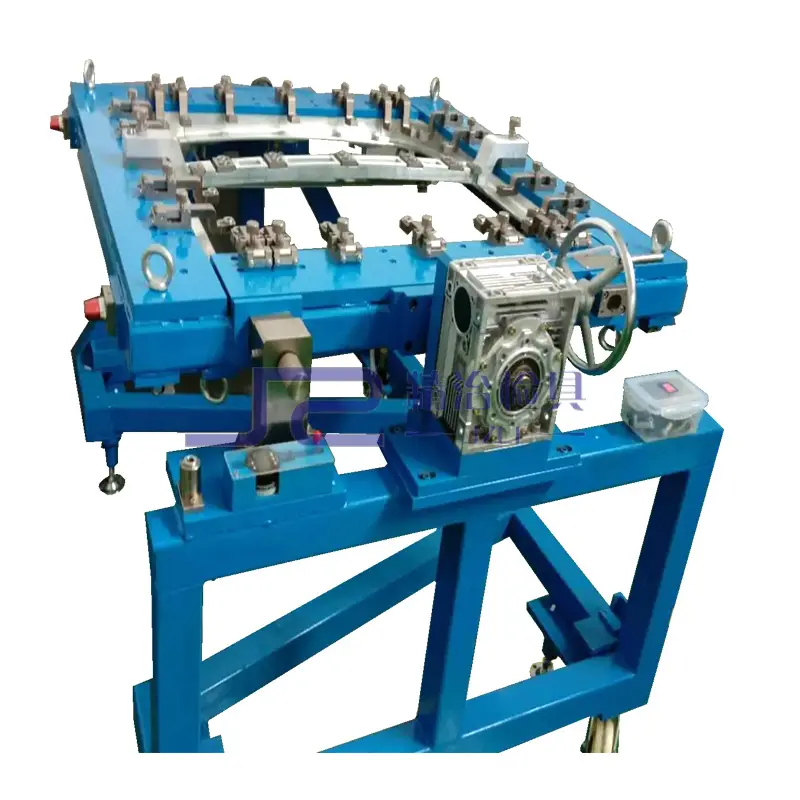

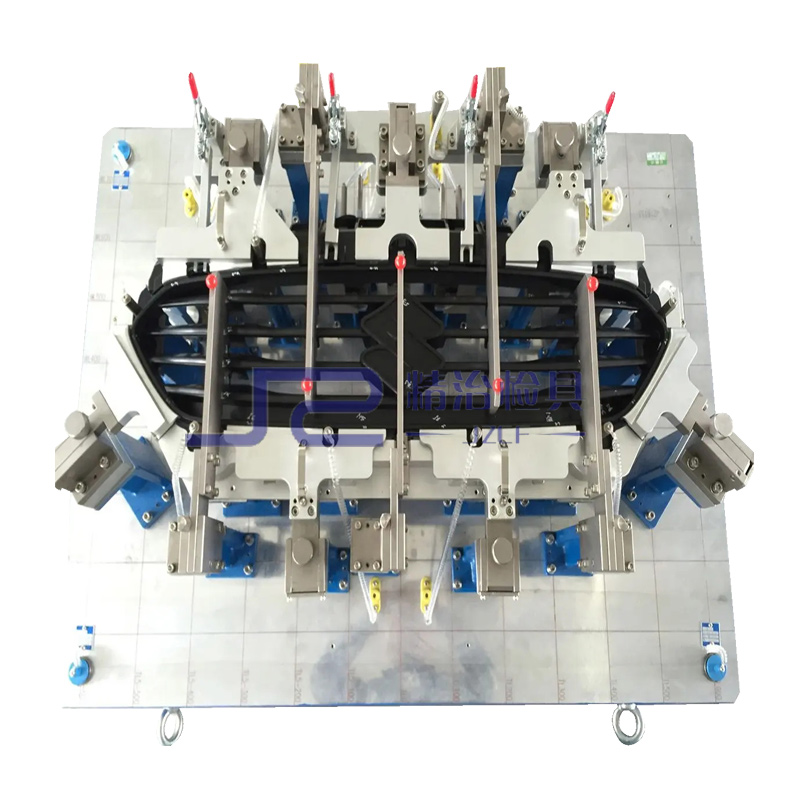

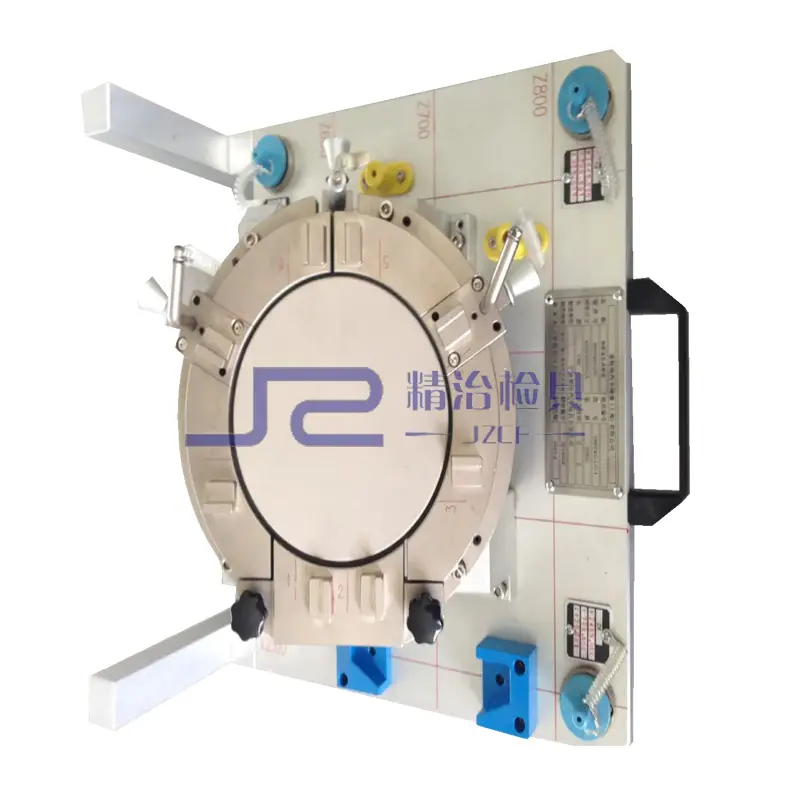

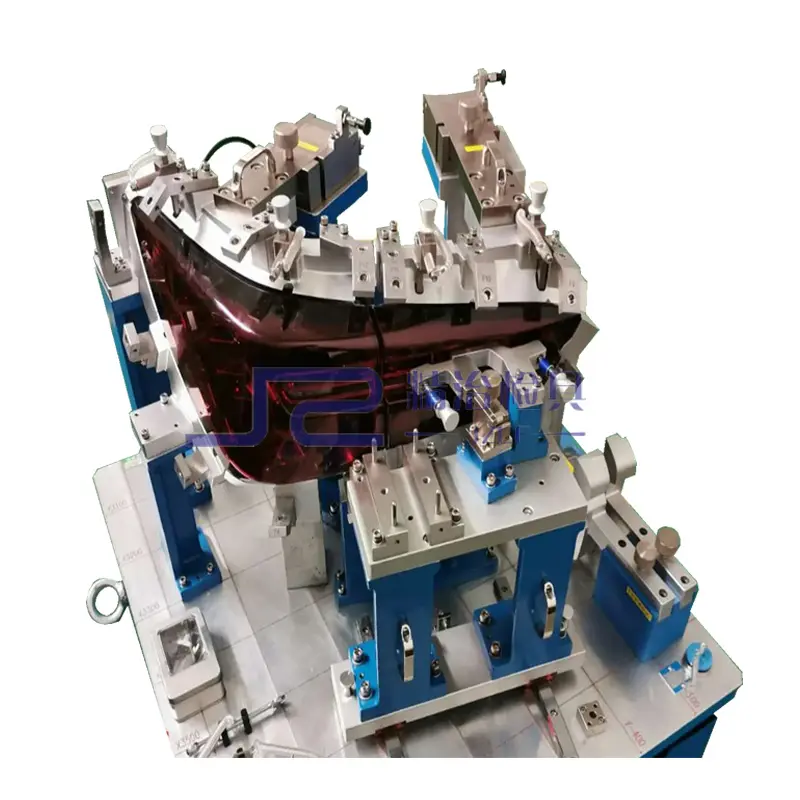

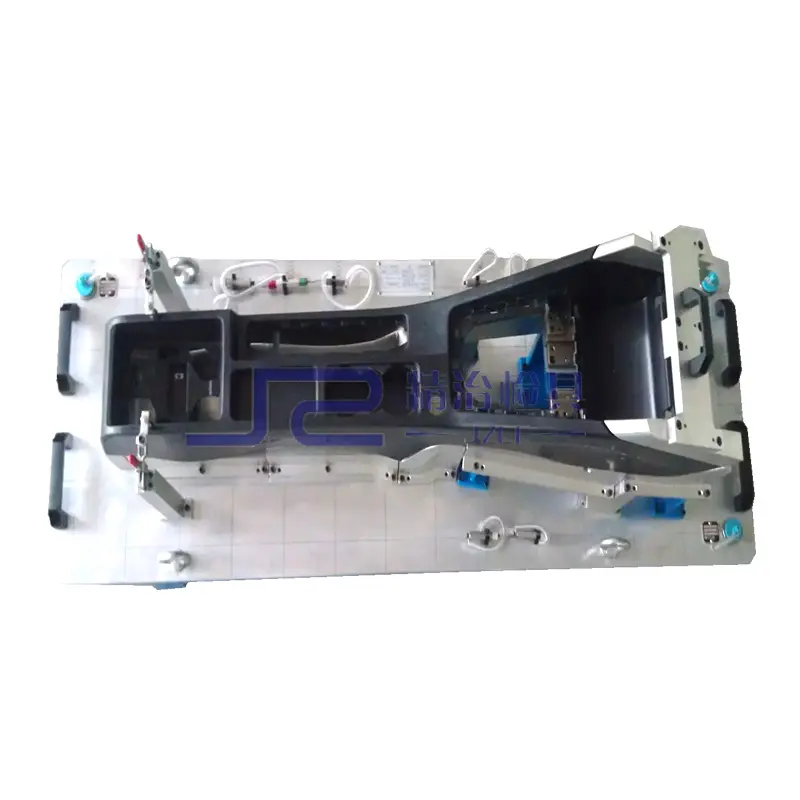

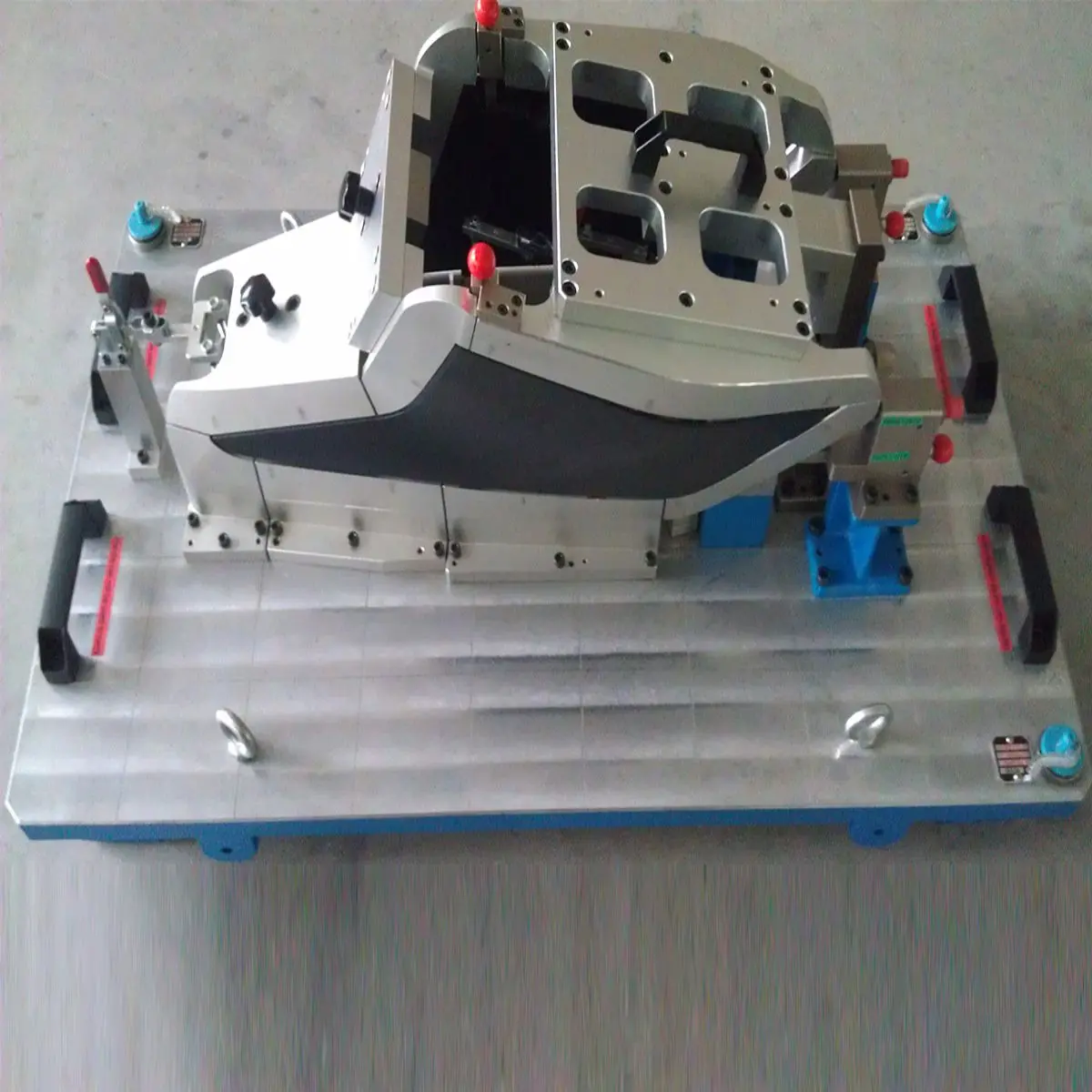

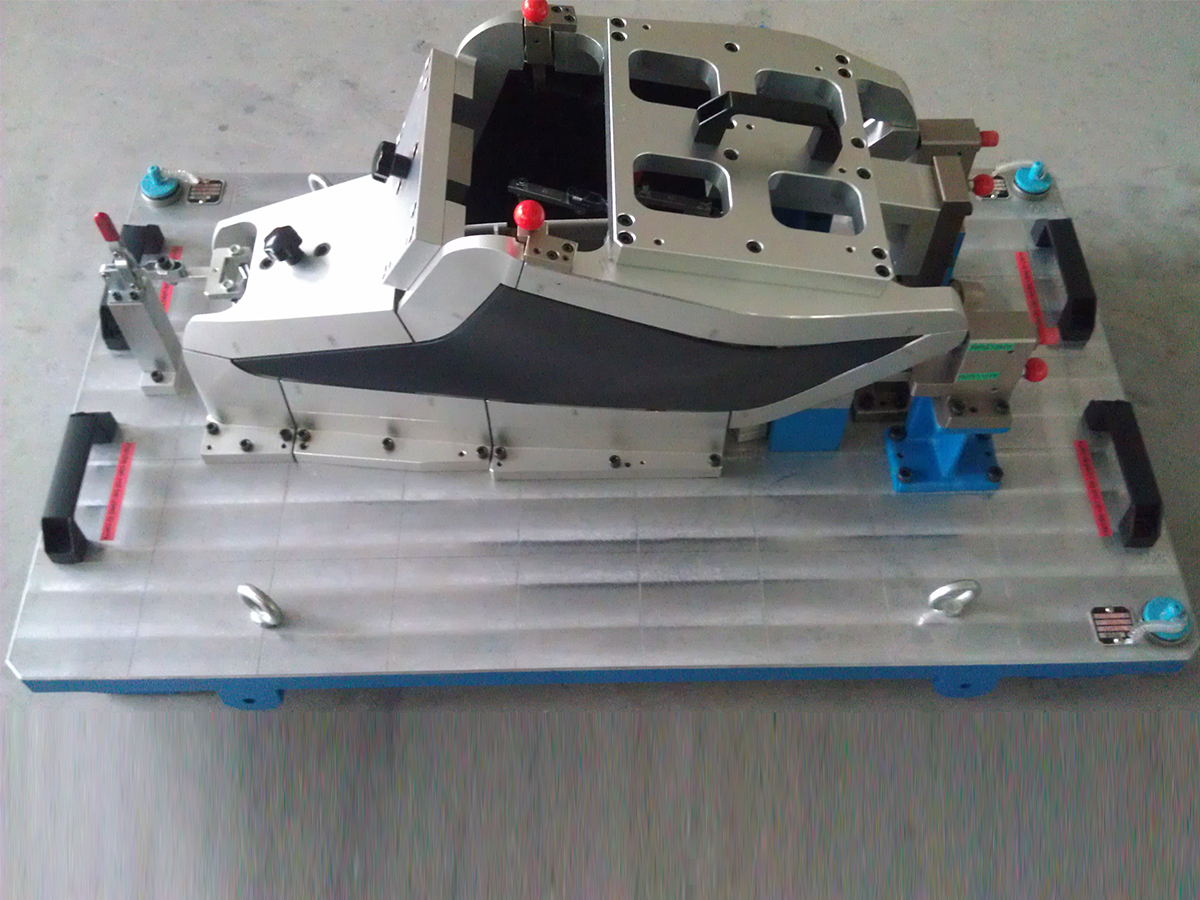

Checking fixture high-quality auxiliary fascia console

Product Description

In addition to quality control, the use of inspection tools can increase the efficiency of the manufacturing process. These tools are designed to check sub-dashboards quickly and accurately, saving time and labor costs while increasing productivity. By automating the inspection process, manufacturers can streamline operations and reduce the possibility of human error, ultimately improving the overall efficiency of the production line.

The use of inspection tools helps improve product reliability. These tools help identify potential flaws and issues in a subdashboard, thereby improving its overall reliability. By addressing these issues early, manufacturers can reduce customer complaints and recall costs related to quality issues, ultimately improving customer satisfaction and brand reputation.

Interior trim checking fixture has high measuring accuracy, not afraid of deformation, low maintenance cost and good convenience. Key product characteristic detection, characteristic line detection, function hole detection, deformation prone area detection during assembly, automobile assembly and production function matching detection. In the production process of auto parts, the realization of online inspection of auto parts ensures the rapid judgment of the quality of auto parts in the production, ensures the safety and processing speed of auto assembly, and improves the quality of auto parts.

In addition to quality and reliability, compliance with regulatory standards is an important consideration in vehicle manufacturing. Use of inspection tools ensures that sub-dashboards comply with relevant safety standards and regulatory requirements. This helps manufacturers avoid penalties for product quality issues and reinforces their commitment to producing safe, compliant automotive products.

The use of automotive sub-instrument panel inspection tools is crucial for the automotive manufacturing industry to improve product quality, increase production efficiency, and ensure compliance. These tools enable manufacturers to conduct comprehensive quality control assessments to identify and resolve any potential issues early in the production process. By leveraging inspection tools, automakers can adhere to the highest quality and compliance standards, ultimately providing consumers with reliable and safe products. Therefore, the use of automotive instrument panel inspection tools is an indispensable asset for manufacturers seeking to maintain a competitive advantage in the automotive market.

description2