01

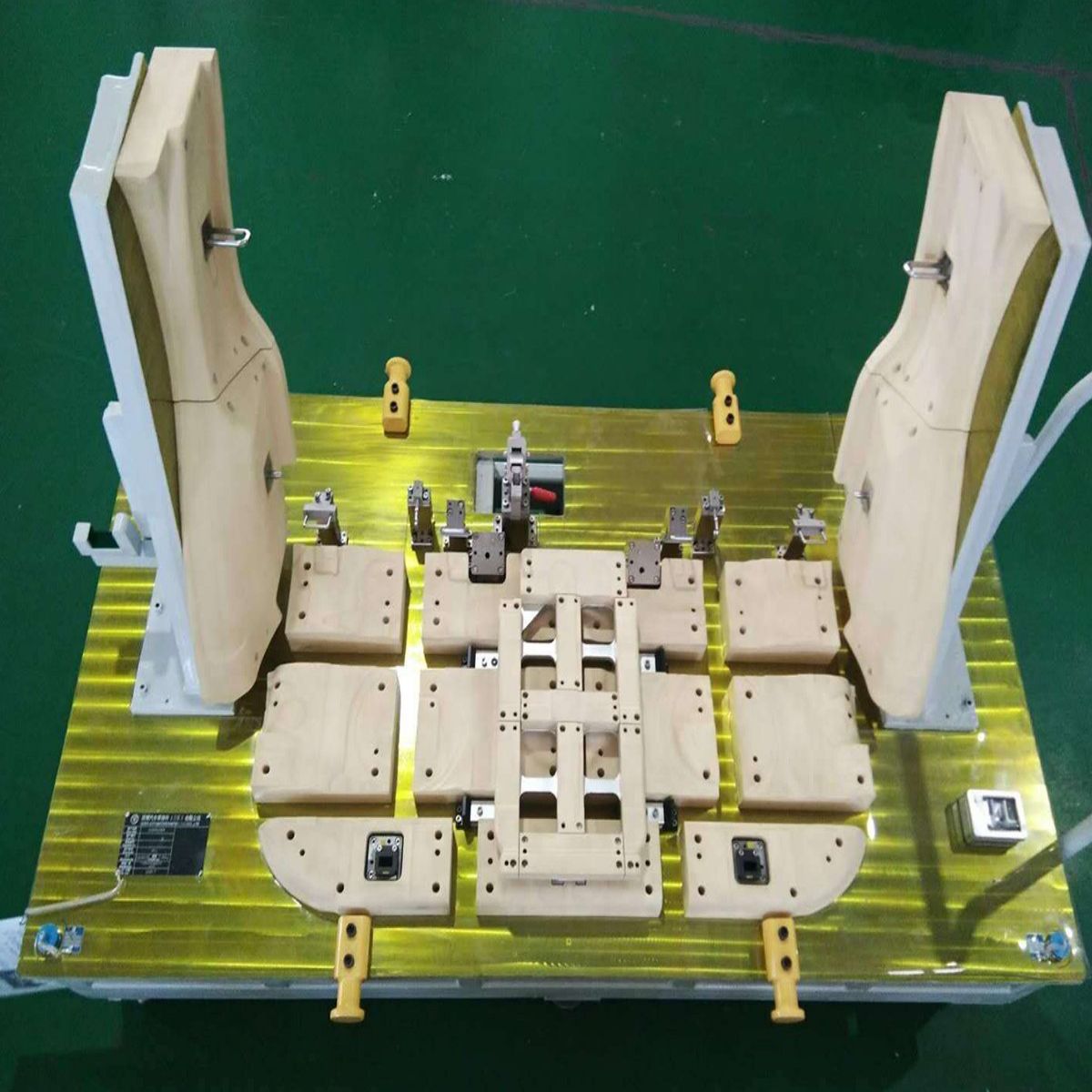

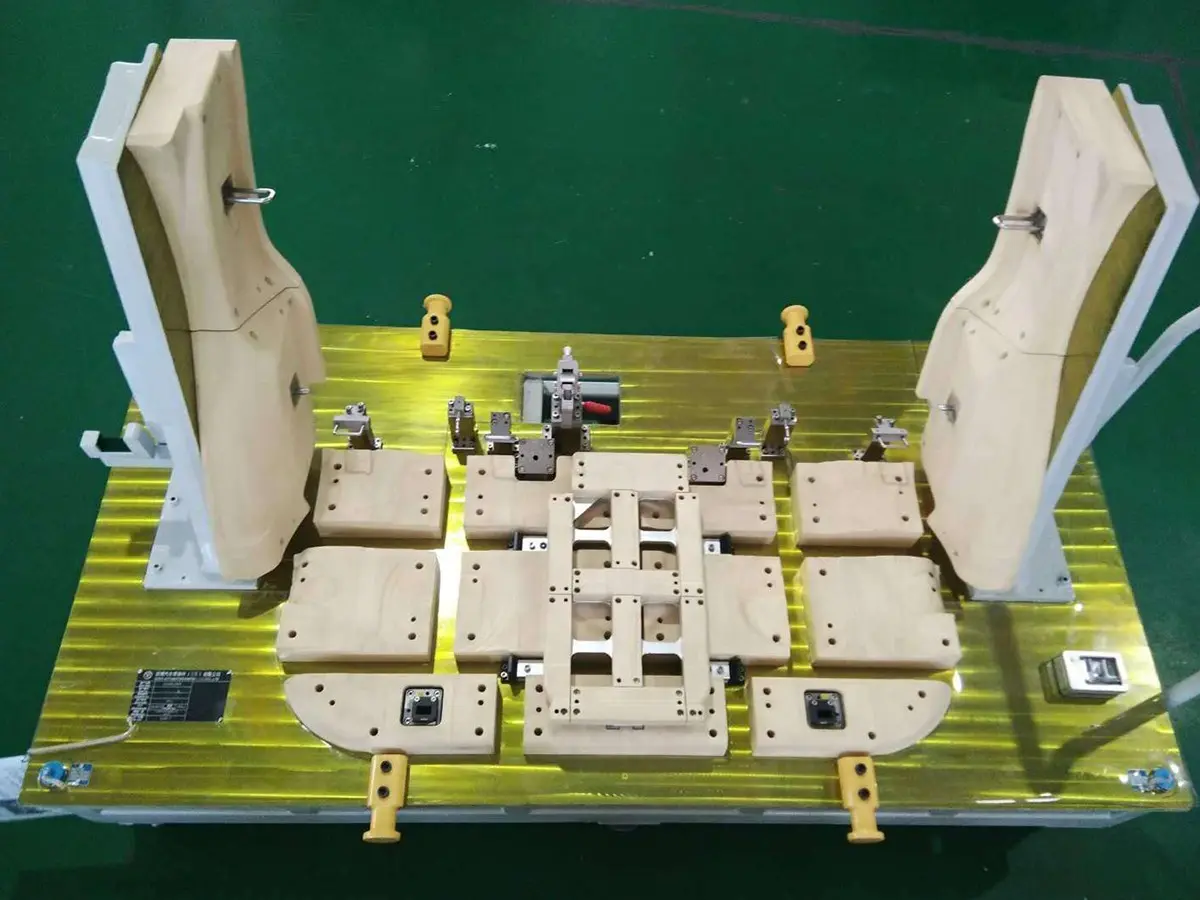

Checking fixture car seat gage improves seat safety

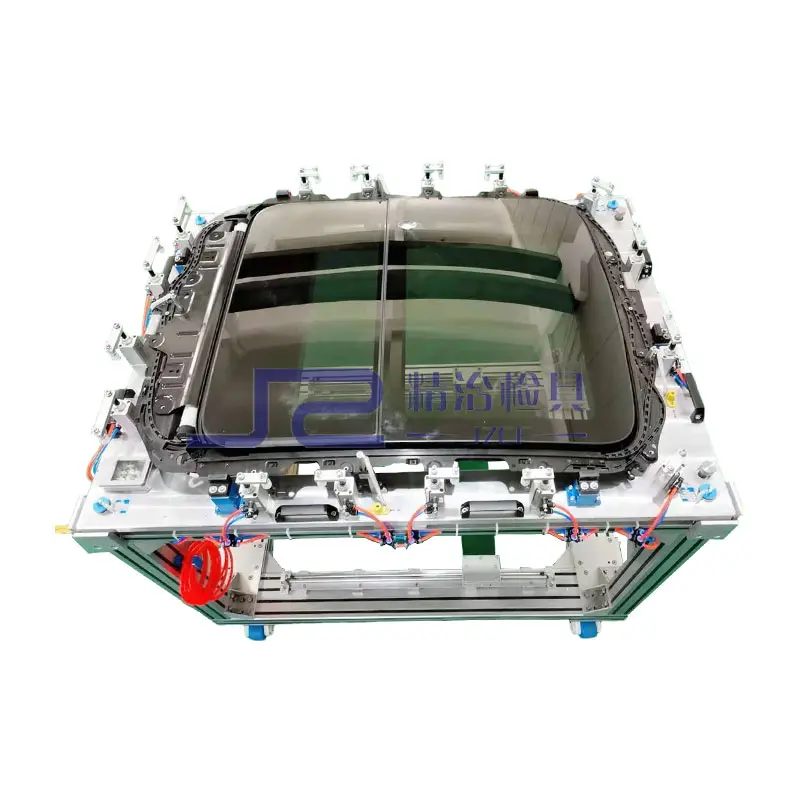

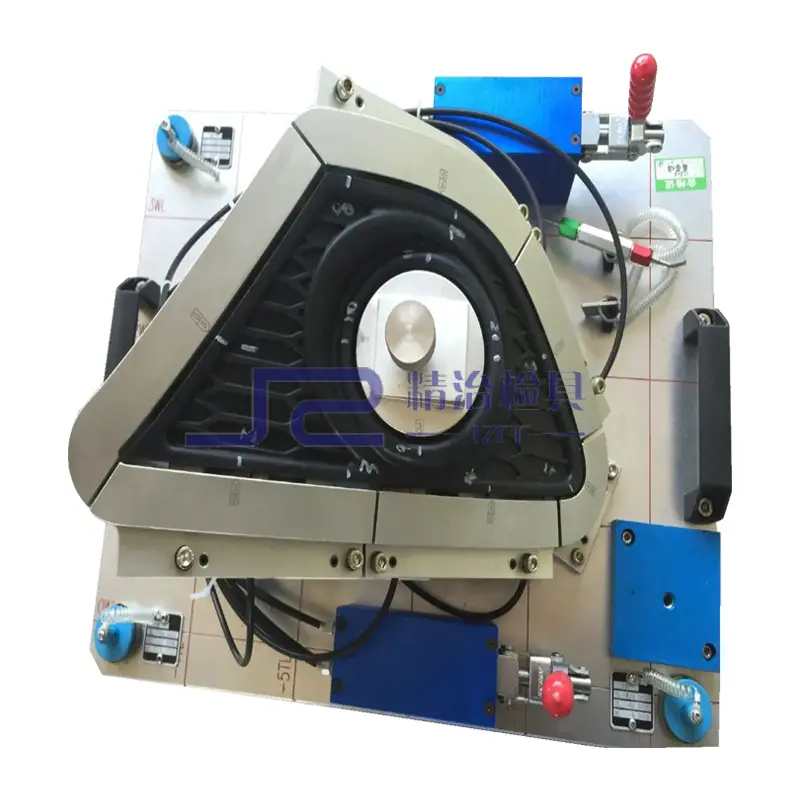

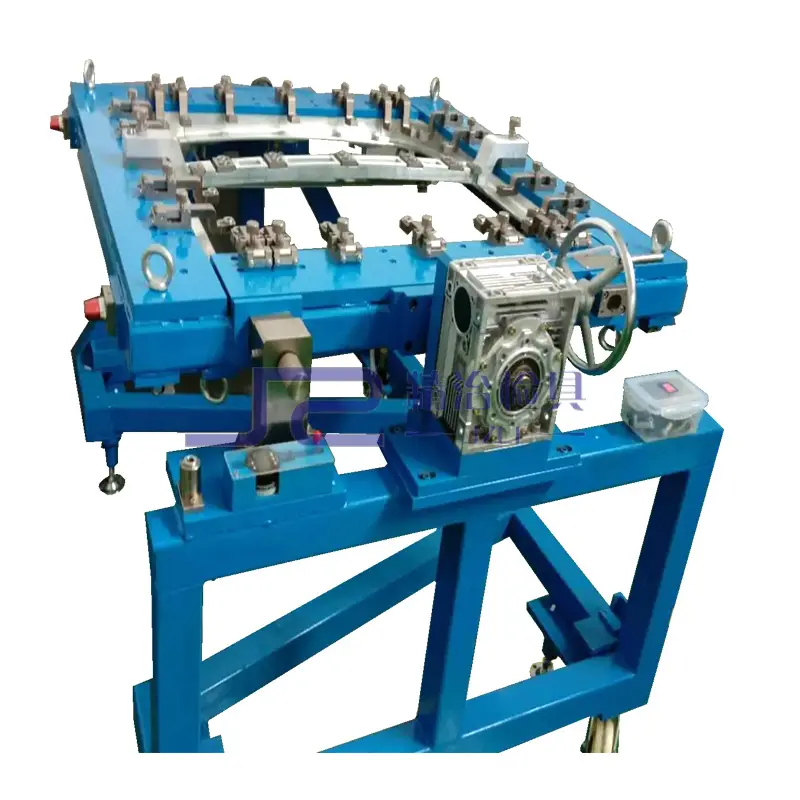

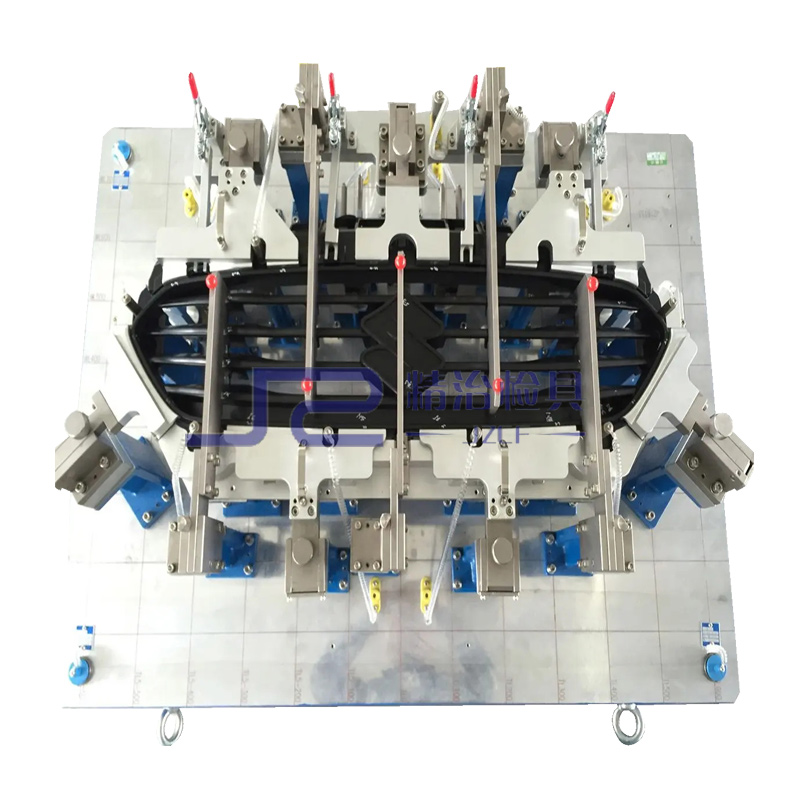

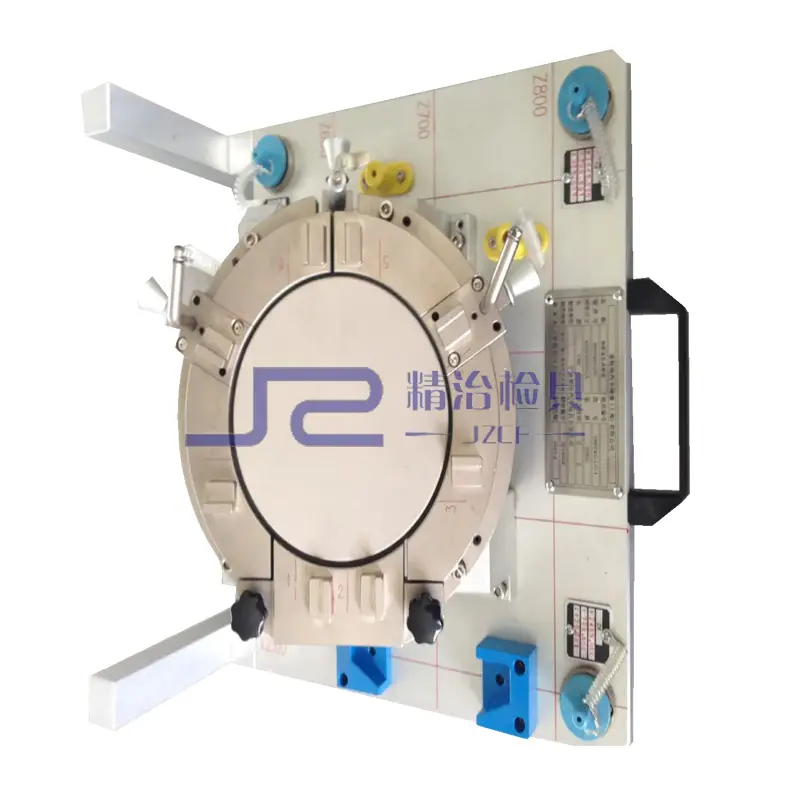

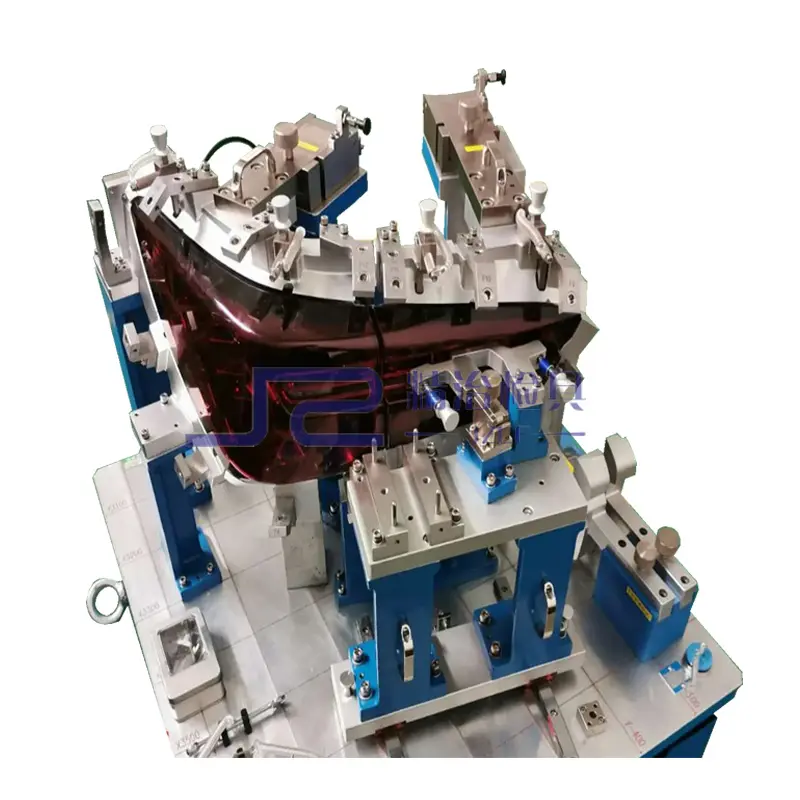

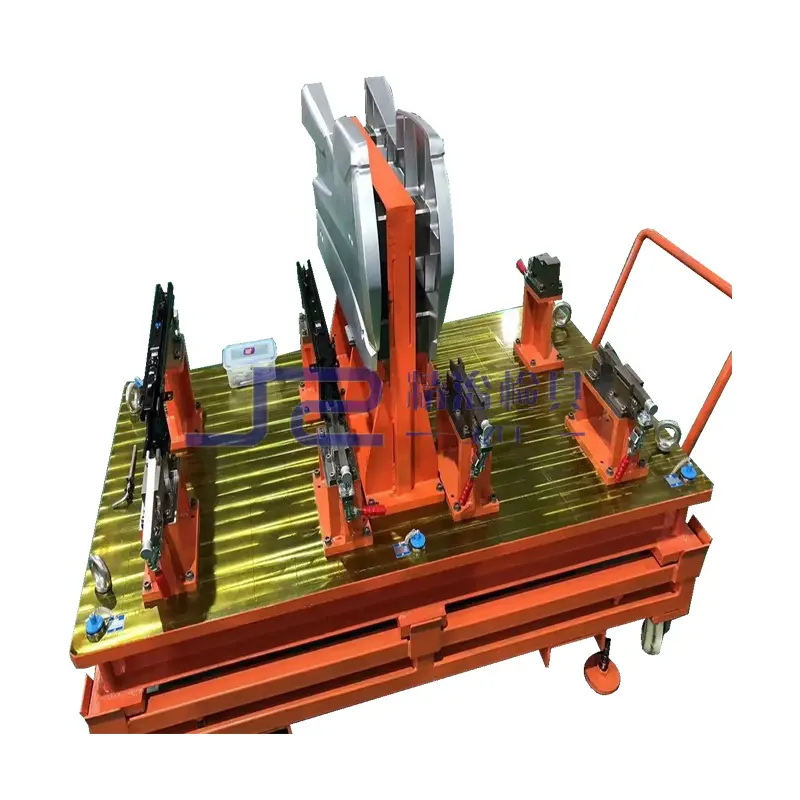

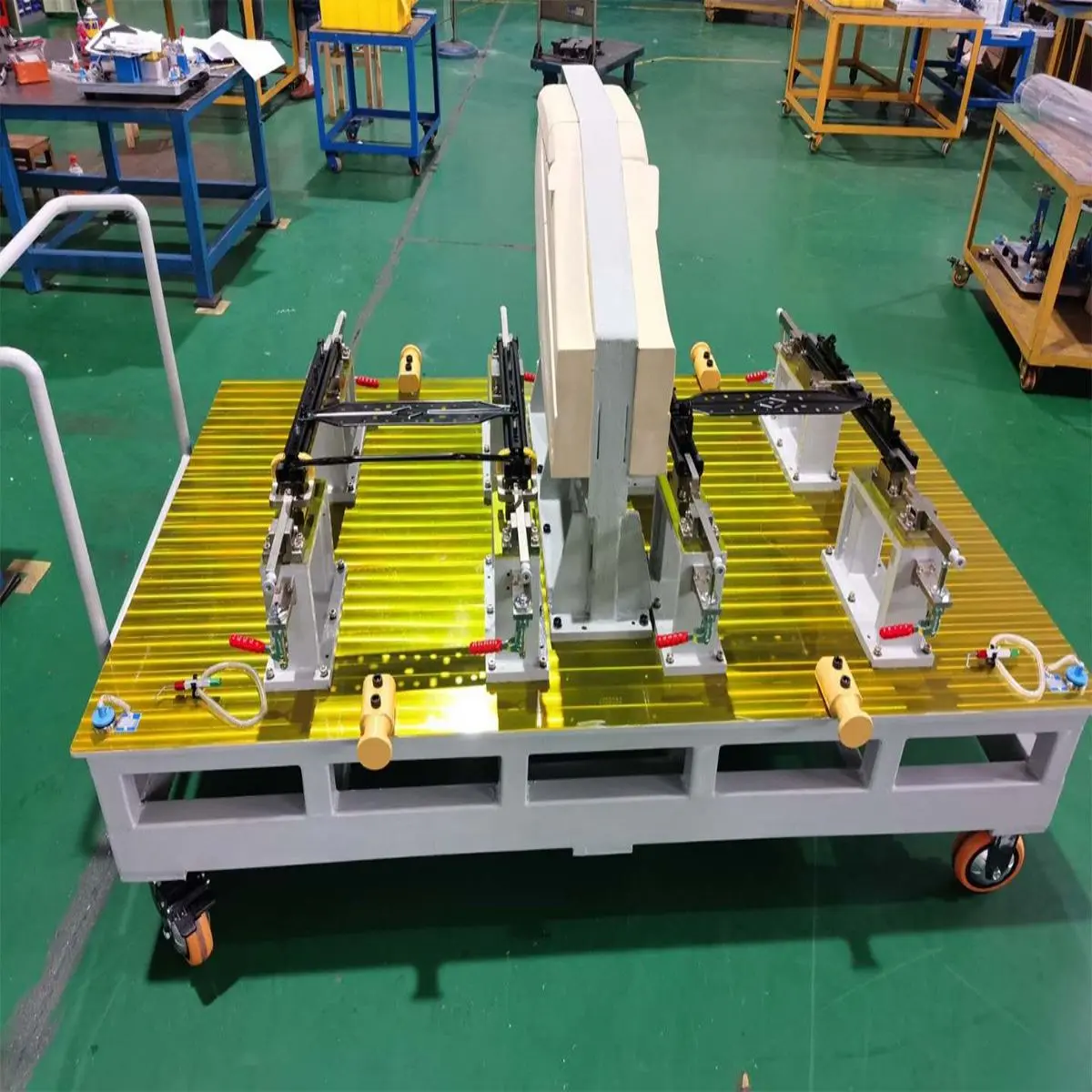

Product Description

One of the most important functions of a seat inspection tool is to measure car seat dimensions. This includes the dimensions of the seat itself, as well as the dimensions of seat belts and other safety restraints. By accurately measuring these dimensions, manufacturers can ensure that car seats are correctly sized and designed to provide maximum safety and comfort for the occupants.

In addition to measuring dimensions, seat inspection tools evaluate the strength and durability of the materials used in car seats. This is critical to ensuring that car seats can withstand the rigors of daily use and provide long-term safety and reliability for passengers. By testing the strength of materials such as metals, plastics and fabrics, manufacturers can identify potential weaknesses and make necessary improvements to improve the overall quality of car seats.

Additionally, seat inspection tools play a vital role in evaluating the performance of seat belt systems. Seat belts are the primary safety feature of car seats and must ensure they function properly to protect the occupants in a crash. Inspection tools accurately measure seat belt tension and locking mechanisms, providing manufacturers and regulators with valuable data to confirm they meet safety standards.

Checking fixture has high measurement accuracy, no fear of deformation, low maintenance cost and good convenience. Key product characteristic inspection, characteristic line inspection, function hole inspection, area detection which is prone to deformation in assembly process, for automobile assembly and production function matching inspection. In the production process of automotive parts, on-line inspection of automotive parts is realized, which ensures the rapid judgment of the quality status of automotive parts in production, ensures the safety and processing speed of automotive assembly, and improves the quality of automotive parts.

By using seat inspection tools during the production process, manufacturers can identify and resolve any potential quality issues before car seats are installed on vehicles. This proactive approach not only ensures the safety and reliability of car seats but also helps manufacturers avoid costly recalls and reputational damage due to safety issues.

Seat inspection tools are integral to ensuring the quality and performance of car seats in the automotive industry. By accurately measuring dimensions, assessing material strength and testing seat belt systems, these tools provide valuable insights to manufacturers and regulators, allowing them to verify compliance with safety standards and regulations. Ultimately, the use of seat inspection tools plays a vital role in improving the overall safety and quality of car seats, giving both manufacturers and consumers peace of mind.

description2