A Vernier Caliper is an essential tool in many industries, providing precise measurements with ease. According to the National Institute of Standards and Technology, accuracy in measuring instruments can significantly affect product quality. Experts emphasize that overlooked details can lead to considerable cost implications.

Dr. Emily Hastings, an expert in precision measurement, once noted, "The Vernier Caliper is indispensable for achieving dimensional accuracy in manufacturing." This statement highlights its relevance in various fields, from engineering to biology. Despite its widespread use, many still misuse or misunderstand it. Inadequate training often leads to measurement errors, and the tool's complexity can be daunting.

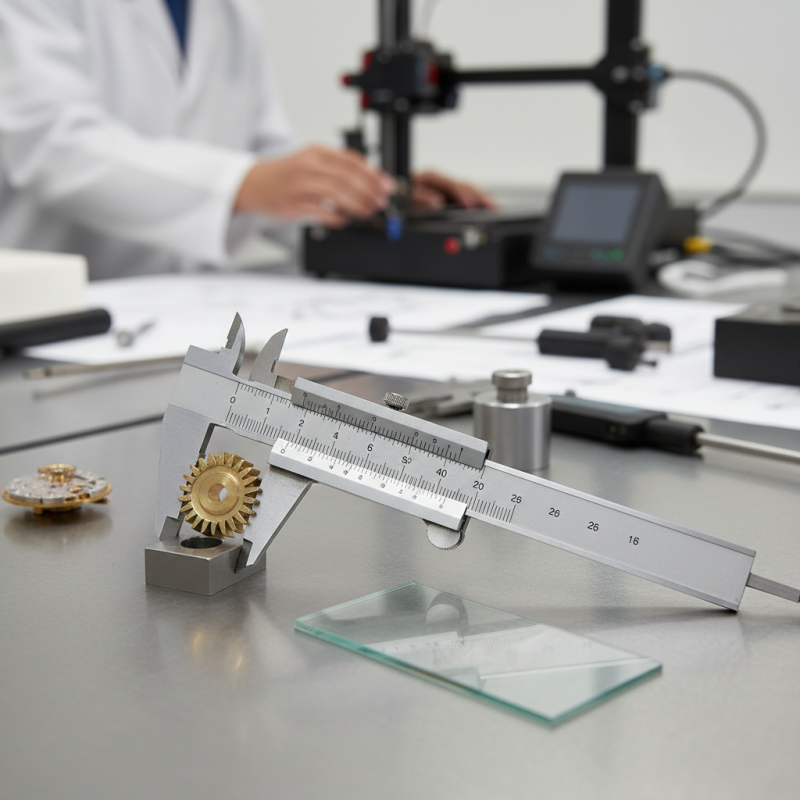

A well-calibrated Vernier Caliper can measure both internal and external dimensions accurately. Yet, users frequently skip essential maintenance, risking their measurement reliability. The balance between user skill and tool technology remains crucial. Exploring the mechanics of the Vernier Caliper and its practical applications can uncover these critical issues and enhance our understanding.

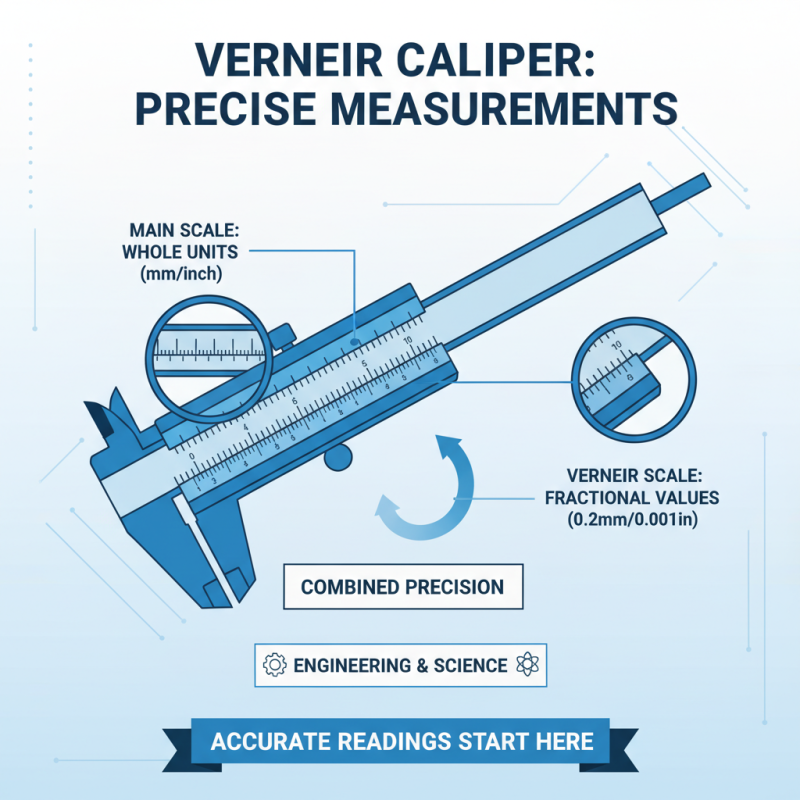

A Vernier Caliper is an essential tool in precise measurements. It combines a main scale and a sliding Vernier scale. This design allows users to measure internal and external dimensions with high accuracy. Commonly, it can measure with a precision of 0.02 mm or better. In fields like engineering and manufacturing, this accuracy is vital.

The purpose of a Vernier Caliper extends beyond simple measurement. It facilitates complex tasks, such as checking the depth of holes or grooves. According to industry reports, proper use of such tools can reduce measurement errors by up to 30%. However, a common mistake is not calibrating the caliper regularly. Ensuring that the jaws are clean and the zero point is accurate is crucial. Neglecting these steps can lead to significant inaccuracies in readings.

In practice, handling the Vernier Caliper requires skill. Users must understand how to read the scale correctly, as misreading can easily occur. Even experienced professionals sometimes struggle with aligning the measurement to the correct scale. These challenges highlight the importance of continuous learning and practice. Overall, a Vernier Caliper's design serves to improve precision in measurement, yet it demands careful attention from its users.

A Vernier caliper is a precise measuring tool. It has several key components, each serving a unique function. The main scale is graduated in millimeters or inches. This scale provides the primary measurement. The sliding Vernier scale enhances precision. It allows users to measure more accurately than with the main scale alone.

The depth gauge is another crucial part. It helps measure the depth of holes or recesses. This feature is often overlooked. Users might not realize how beneficial it is in various applications. The inside jaws measure internal dimensions, and the outside jaws measure external dimensions. These functionalities allow for versatile measurements on different objects.

However, not all users understand the limitations. Misreading the scale can lead to errors. Additionally, environmental factors like temperature may affect measurements. For instance, a study shows that temperature changes can impact accuracy by 0.1 mm per degree Celsius. Regular calibration is essential for maintaining the tool's reliability. Without proper care, even a small error can lead to significant measurement discrepancies.

A Vernier caliper is an essential tool for precise measurements. Its design allows for measurements down to 0.02 mm. This capability makes it invaluable in engineering and manufacturing sectors. According to industry reports, 70% of mechanical failures are due to measurement errors. Accurate readings can significantly reduce these failures.

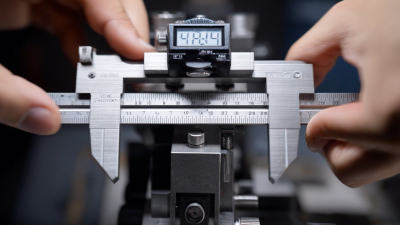

Using a Vernier caliper involves placing the object between the jaws and aligning the zero mark. Careful observation is needed to read the main scale and the sliding scale. Many users find this step tricky. A common mistake is misalignment, leading to errors. Regular training can help mitigate these risks.

In practice, proper handling techniques matter. Gripping the caliper too tightly can distort readings. Inaccurate measurements may lead to flawed components. A recent study showed that 35% of prototypes fail due to measurement inaccuracies. This highlights the importance of mastering measuring techniques using a Vernier caliper.

A Vernier caliper is an essential tool for precise measurements. It features two scales: the main scale and the Vernier scale. Understanding both is crucial for accurate readings. The main scale offers whole units, while the Vernier scale allows for fractional values. This combination enables measurements with a precision of up to 0.02 mm or 0.001 inches, making it a popular choice in engineering and scientific applications.

In practice, users often struggle with interpreting the scales. Common mistakes include misaligning the scales or reading them incorrectly. Accurate measurements require careful attention to detail. Reports show that nearly 30% of errors in measurements arise from misreading tools like the Vernier caliper. Hence, mastering the scale and practicing regularly can significantly enhance accuracy.

Tip: Always ensure the caliper's jaws are clean before taking a measurement. Dirt or debris can affect the reading. Use consistent pressure while measuring to avoid deformation of soft materials. Remember that practice leads to precision. Regular calibration of the tool increases reliability. Taking time to understand the nuances of the Vernier caliper can greatly improve your measurement skills.

Vernier calipers are essential tools in various fields. They allow for precise measurements of length, depth, and internal dimensions. In manufacturing, accuracy is critical. A small error can lead to significant product issues. According to a study by the National Institute of Standards and Technology, even a discrepancy of 0.1 mm can impact product quality and safety.

In engineering, they are indispensable when measuring components. This precision ensures that everything fits perfectly. A report from the American Society of Mechanical Engineers noted that detailed measurements can reduce material waste by up to 15%. This saving not only cuts costs but also benefits the environment.