In the modern manufacturing landscape, precision is paramount. Many industries heavily rely on Die Fixture to achieve high accuracy in machining tasks. Reports indicate that the precision machining market is expected to grow significantly, reaching over $100 billion by 2025. This growth underscores the importance of effective tools, such as Die Fixtures, that ensure repeatability and accuracy in production.

Die Fixtures are essential for aligning and securing components during machining. They help reduce errors that can arise from misalignment, leading to increased production costs. According to a survey conducted by the Precision Measurement Association, 40% of manufacturers report issues due to improper workholding. Such data highlights the necessity of utilizing Die Fixtures in workshops and factories.

While Die Fixtures enhance precision, they are not without challenges. Designing the right fixture can be complex and may require iteration. Manufacturers often grapple with balancing cost and functionality. Inadequate knowledge or training in using Die Fixtures can lead to suboptimal outcomes, reinforcing the need for continual improvement in training and practices. It's a reminder that even the best tools require thoughtful application and understanding for maximum benefit.

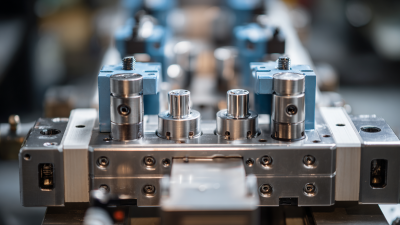

Die fixtures play a crucial role in manufacturing. They serve as specialized tools that hold and support workpieces during machining processes. This ensures accurate, repeatable results. A well-designed die fixture helps maintain precise alignment. It reduces the chance of errors in dimension.

Understanding die fixtures can illuminate their importance. They help streamline production workflows. Consistent use of die fixtures can lead to better product quality. However, not all die fixtures are ideal for every task. Some may limit flexibility. Others can require frequent adjustments, leading to inefficiencies.

It's essential to reflect on the design of these fixtures. A poor design can cause misalignment. It may also waste time during setup. Manufacturing tasks demand precision, and even small mistakes can have significant consequences. Focusing on the right type of die fixture can enhance productivity, but it also requires continuous evaluation and improvement.

| Die Fixture Type | Material Used | Precision Level | Common Applications | Advantages |

|---|---|---|---|---|

| Modular Die Fixture | Aluminum | ±0.01 mm | Stamping, Cutting | Versatile, Lightweight |

| Dedicated Die Fixture | Steel | ±0.005 mm | High-Volume Production | High Durability, Enhanced Accuracy |

| Quick Change Die Fixture | Composite Materials | ±0.02 mm | Short Runs, Prototyping | Fast Changeover, Cost-Effective |

| Custom Die Fixture | Titanium | ±0.003 mm | Precision Aerospace Parts | Superior Strength, Lightweight |

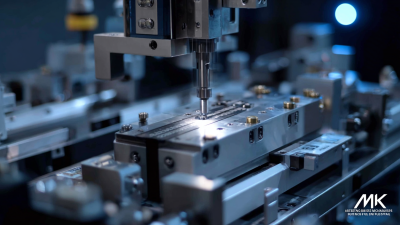

Die fixtures are essential tools in manufacturing for achieving precision. They hold workpieces in place during machining or assembly. Understanding their components is crucial for effective use. Each part of the die fixture has a specific function that supports accurate production.

The base is the foundation. It supports the fixture and ensures stability. A well-designed base minimizes vibrations during machining. Clamping devices then secure the workpiece. These can be manual or automated. According to industry reports, improper clamping can lead to a 15% increase in defects. Such data emphasizes the importance of proper fixture design.

Additionally, locating pins help in accurate positioning. These pins align the workpiece precisely, reducing errors. Hollow tubes for coolant flow can also be an integral part. They keep the workpiece cool during machining. Yet, many forget to address maintenance for these fixtures, leading to decreased effectiveness over time. Regular checks ensure reliable performance and enhance longevity. Awareness of these components can vastly improve manufacturing tasks.

Setting up a die fixture requires careful planning and precision. Begin by selecting the right materials, as the choice affects durability and accuracy. Reports indicate that 70% of manufacturing defects originate from improper setups. This emphasizes the importance of a meticulous approach. Prepare your workspace to minimize clutter. A clean environment can boost focus and efficiency.

Next, align your die fixture with calibration tools. Accuracy ensures that components are shaped correctly. Use measuring tools to check alignment regularly. Studies suggest that misalignments can lead to costly errors. Ensure all fasteners are tightened appropriately. Loose components can shift during manufacturing, causing flaws in the final product. Take the time to double-check every step before proceeding.

Incorporate feedback loops into your process. Engage operators in discussions about fixture performance. Their insights can highlight unexpected challenges. Regular training should be conducted to refine skills. Remember, imperfections highlight areas for improvement. Continuous assessment not only enhances quality but also fosters a culture of innovation.

Die fixtures play a crucial role in achieving precision during manufacturing tasks. To maximize their effectiveness, it's essential to focus on several best practices. Proper alignment of the die fixtures is key. Misalignment can lead to errors in production, which may have costly consequences. Ensure that all components are level and properly secured before starting.

Maintaining the die fixtures is also important. Regular cleaning prevents build-up that can affect the machining process. Lubrication is essential too; it reduces friction and wear. Inspecting the fixtures for any signs of damage or wear will help avoid unexpected downtimes.

Training personnel on the importance of using die fixtures correctly cannot be overlooked. They must understand how to set them up and troubleshoot problems. Knowledge gaps can lead to mistakes in handling, affecting product quality. Reflecting on past experiences can enhance future operations.

Die fixtures are essential tools in manufacturing. They help ensure precision and repeatability. However, users often face challenges while using them. One common issue is alignment. Misalignment can lead to defective parts. It's vital to check the setup before starting any job.

Another challenge is wear and tear of die fixtures. Over time, components may degrade. Regular inspection and maintenance are crucial. Replace worn-out parts promptly. This helps maintain consistent quality.

Tips: Always document the setup process. This will help in troubleshooting any issues later. Using measuring tools can enhance accuracy. Remember to keep the workspace organized. A clutter-free area reduces mistakes and speeds up production.

This chart illustrates common challenges faced when using die fixtures in manufacturing tasks. The challenges are assessed based on their impact percentage, showcasing the need for effective solutions in areas such as precision, setup time, material wear, cost efficiency, and maintenance.