In the realm of manufacturing, precision quality control is paramount to ensuring product consistency, reliability, and performance. Among the various tools employed to uphold these standards, Measuring Fixtures stand out as essential components that facilitate accurate measurement and inspection of parts and assemblies. These fixtures not only streamline the quality control process but also enhance productivity by reducing the time needed for measurement while minimizing human error.

Selecting the right Measuring Fixtures is crucial for manufacturers aiming to achieve high levels of precision. Each type of fixture serves a specific purpose, whether it’s for dimensional analysis, assembly verification, or functional testing. Understanding the diverse options available can empower manufacturers to make informed decisions that align with their operational needs and quality targets. In this article, we will explore the top 10 Measuring Fixtures that are integral to effective quality control in manufacturing, detailing their unique features, advantages, and applications. With this knowledge, manufacturers can enhance their measurement processes and ultimately improve product outcomes.

In the world of manufacturing, precision measuring fixtures play a crucial role in maintaining quality control. These fixtures ensure that components meet specific dimensions and tolerances, significantly reducing the likelihood of defects. By integrating precision measuring fixtures into the production process, manufacturers can achieve a high level of accuracy, leading to increased efficiency and reduced waste. This focus on precision not only enhances product quality but also fosters greater customer satisfaction.

Tips for implementing precision measuring fixtures: Include selecting the right type of fixture for your needs and ensuring proper training for your operators. Regular calibration and maintenance of these fixtures are vital to preserving their accuracy over time. Additionally, adopting a systematic approach to measuring and documenting results can help identify trends and areas for improvement, ultimately driving continuous quality enhancements.

Another effective strategy is to leverage technology in your measuring processes. Utilizing digital measuring fixtures can provide real-time data, facilitating faster decision-making and enabling immediate corrective actions. Investing in modern measuring equipment will also ensure compliance with industry standards and help maintain a competitive edge in the market. Embracing these best practices will lead to substantial improvements in quality control and overall manufacturing performance.

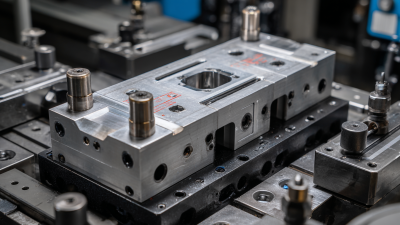

Measuring fixtures play a crucial role in ensuring precision quality control within various manufacturing sectors. These specialized tools are designed to hold a workpiece securely in place during measurement processes, allowing for accurate assessments of dimensions, shapes, and tolerances. One common type of measuring fixture is the height gauge fixture, which is extensively used in machining and inspection stations to measure vertical dimensions against a calibrated scale. This fixture provides high repeatability and enables operators to easily verify if manufactured parts meet design specifications.

Another important category is the coordinate measuring machine (CMM) fixtures. These fixtures are integral in industries where complex geometries are common, such as aerospace and automotive manufacturing. CMM fixtures allow for three-dimensional measurements and can accommodate various probes for different features, thus enhancing versatility. Additionally, the use of optical measuring fixtures has gained popularity for applications requiring non-contact measurement, such as in the electronic and medical device industries, where precision is paramount. Each type of measuring fixture serves a unique purpose, tailored to meet the specific needs of the manufacturing process, ultimately contributing to improved quality assurance.

Measuring fixtures play a crucial role in ensuring precision quality control

in manufacturing environments. High-quality measuring fixtures are characterized by several key features

that enhance their accuracy and reliability. One essential feature is the use of robust materials

that minimize deformation under load, providing stability during measurements.

Materials like hardened steel or aluminum alloys not only ensure durability but also help maintain the

consistent geometric precision required in high-stakes manufacturing settings.

Measuring fixtures play a crucial role in ensuring precision quality control

in manufacturing environments. High-quality measuring fixtures are characterized by several key features

that enhance their accuracy and reliability. One essential feature is the use of robust materials

that minimize deformation under load, providing stability during measurements.

Materials like hardened steel or aluminum alloys not only ensure durability but also help maintain the

consistent geometric precision required in high-stakes manufacturing settings.

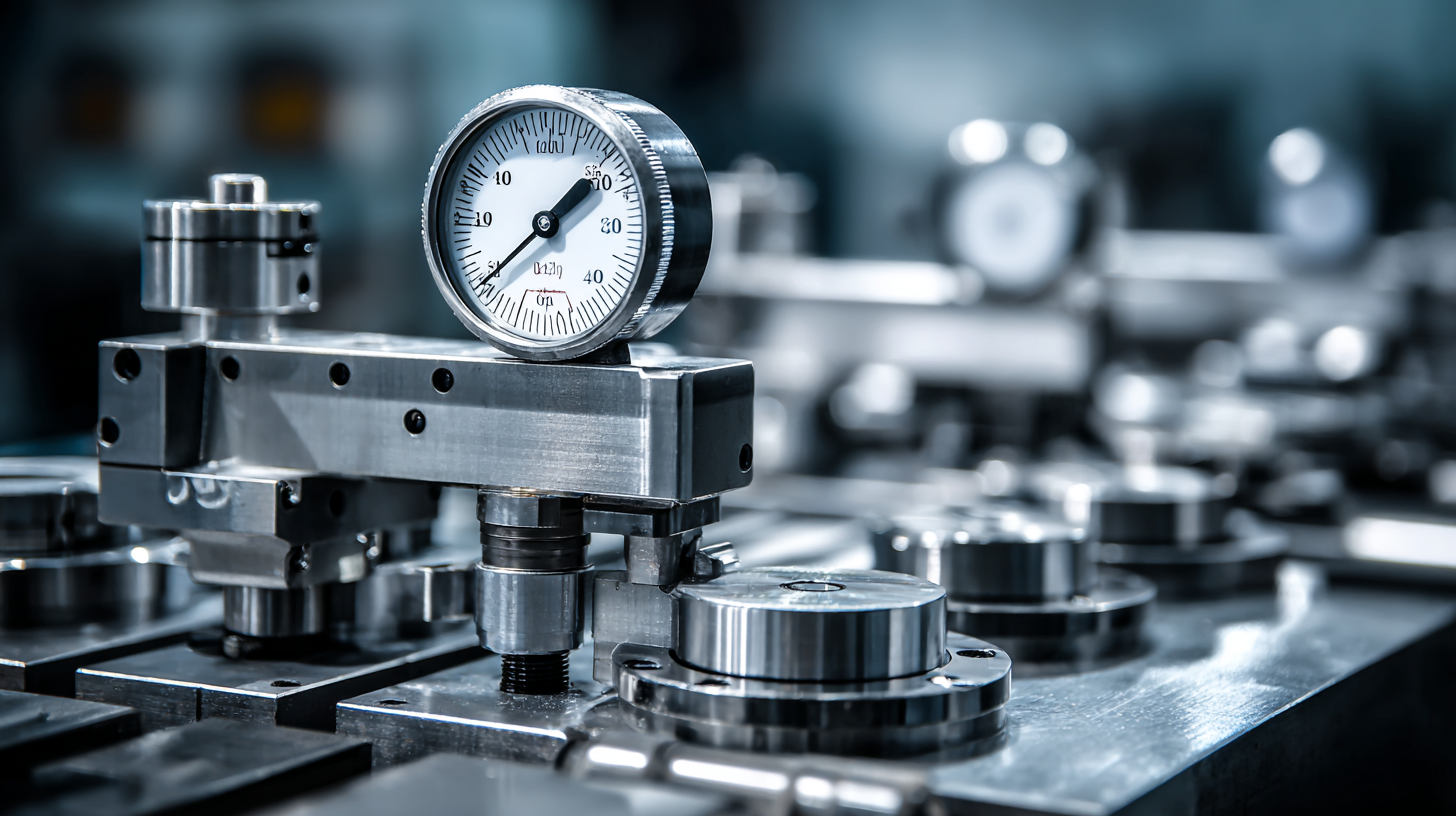

Another vital aspect of high-quality measuring fixtures is their design adaptability. Fixtures that can be easily adjusted or modified accommodate various components and sizes, thus maximizing their utility across multiple processes. Additionally, incorporating advanced measurement technologies, such as digital readouts or laser scanning systems, can significantly improve measurement accuracy and efficiency. These innovations streamline the data collection process, allowing manufacturers to maintain tight tolerances and quickly identify any deviations from quality standards.

Measuring fixtures play a crucial role in enhancing precision quality control within manufacturing processes. Recent data indicates that companies implementing advanced measuring fixtures can reduce inspection times by up to 30%, significantly increasing overall production efficiency. According to a report by the National Institute of Standards and Technology, manufacturers utilizing precision measuring tools experience a reduction in scrap rates by 20%, directly impacting their bottom line. This reduction in waste not only leads to cost savings but also promotes more sustainable manufacturing practices.

Furthermore, the integration of data-driven insights from measuring fixtures allows for real-time quality assurance, enabling manufacturers to identify defects early in the production cycle. A study by the Aberdeen Group found that firms leveraging smart measuring technologies have seen a 15% increase in product quality. The ability to gather and analyze data from measuring fixtures empowers manufacturers to make informed decisions, optimizing processes, and achieving higher standards of quality control. In an industry where precision is paramount, the strategic use of measuring fixtures is transforming how manufacturers operate, driving efficiency and profitability.

In the realm of manufacturing, precision quality control is paramount to ensure product reliability and customer satisfaction. Implementing measuring fixtures can significantly enhance quality control processes. According to a report from the Quality Assurance Institute, organizations that leverage specialized measuring fixtures observe a 20% reduction in defects, leading to increased efficiency and lower production costs. A strategic approach to integrating these tools involves proper training for employees, ensuring they are adept in using the fixtures, which has been shown to improve measurement accuracy by up to 30%.

Moreover, adopting a systematic calibration schedule for measuring fixtures can further optimize quality control processes. A study conducted by the National Institute of Standards and Technology indicated that regular calibration can maintain measurement accuracy within ±0.001 inches, which is critical for high-precision manufacturing sectors like aerospace and automotive industries. By establishing best practices such as routine inspections and meticulous documentation, manufacturers not only comply with industry standards but also foster a culture of continuous improvement, ultimately paving the way for sustained operational excellence.