In the evolving landscape of manufacturing, staying abreast of the latest trends and innovations in Die Fixture technology is crucial for industry professionals. According to Dr. Emily Carter, a leading expert in the Die Fixture field, "The future of manufacturing hinges on our ability to innovate in fixture design and functionality, streamlining processes while ensuring precision." As we approach 2025, it is imperative to explore the advancements that are shaping the Die Fixture industry and understand how these innovations can enhance efficiency and accuracy in production.

The increasing demand for custom solutions and automation is driving significant changes in Die Fixture designs. Cutting-edge materials, smart technology integrations, and responsive designs are just a few of the trends influencing how manufacturers approach their tooling processes. This article will delve into the key innovations that are poised to redefine Die Fixture applications and offer insights into how these changes can elevate operational capabilities. As the shift towards enhanced precision and adaptability continues, understanding these trends will be essential for professionals aiming to maintain a competitive edge in the fast-paced manufacturing sector.

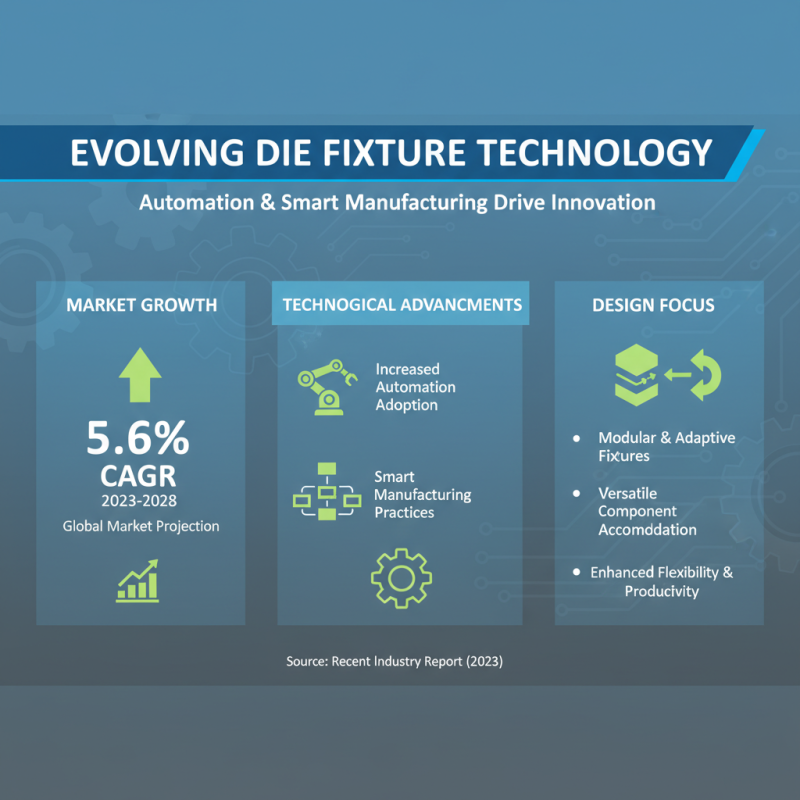

The die fixture design and manufacturing techniques are evolving rapidly, influenced by advancements in technology and growing demands for efficiency. A recent industry report highlighted that the global market for die fixtures is projected to grow at a CAGR of 5.6% from 2023 to 2028, primarily driven by the increasing adoption of automation and smart manufacturing practices. Designers are now focusing on creating modular and adaptive fixtures that can easily accommodate various component sizes and shapes, enhancing both flexibility and productivity on the shop floor.

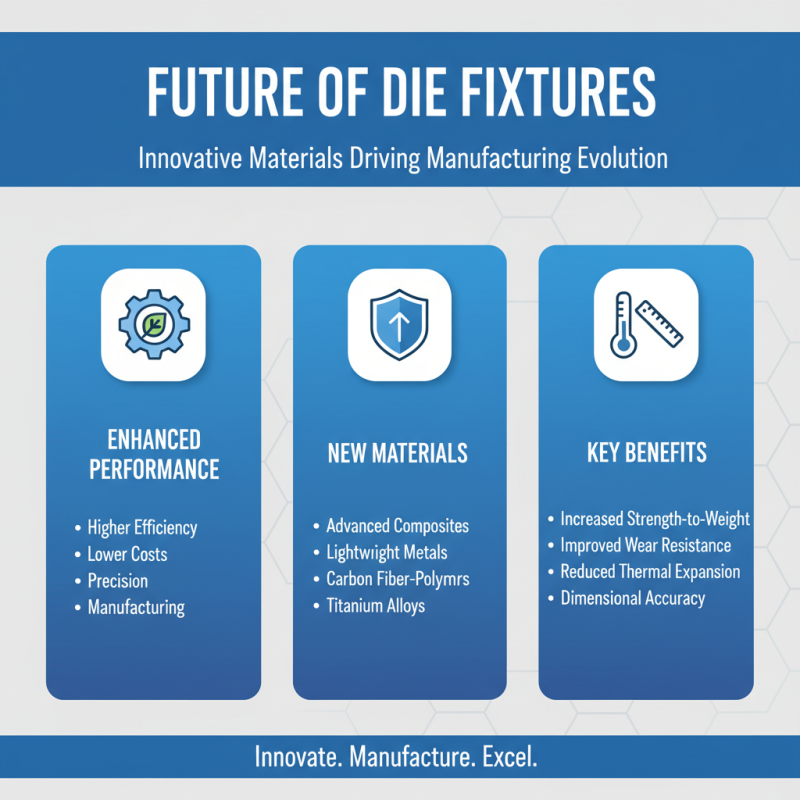

To keep pace with this evolution, manufacturers are embracing advanced materials and techniques. For instance, the integration of lightweight composites and additive manufacturing technologies is allowing for more intricate designs without compromising structural integrity. These innovations not only optimize performance but also reduce production lead times significantly. Furthermore, implementing CAD/CAM systems for die fixture design enables precise modeling and manufacturing, leading to improved accuracy and reduced waste.

**Tip:** When designing die fixtures, consider utilizing simulation software to predict the performance and potential issues early in the process, which can save both time and resources. Additionally, maintaining close collaboration between design and manufacturing teams ensures that real-time feedback can lead to iterative improvements in fixture designs. As trends in sustainability gain momentum, incorporating eco-friendly materials and processes can also position a business favorably in the market.

The future of die fixtures is being significantly shaped by the adoption of innovative materials that enhance performance, durability, and precision in manufacturing processes. As industries strive for higher efficiency and lower costs, the introduction of advanced composites and lightweight metals is transforming traditional die fixture designs. Materials such as carbon fiber-reinforced polymers and titanium alloys offer not only increased strength-to-weight ratios but also improved resistance to wear and thermal expansion, which are critical for maintaining dimensional accuracy in high-volume production runs.

Additionally, the use of smart materials, including shape memory alloys and piezoelectric components, is paving the way for adaptive die fixtures that can respond to different manufacturing conditions in real-time. These materials allow for the design of fixtures that can modify their properties under varying loads and temperatures, ensuring optimal performance across diverse applications. This integration of innovative materials not only enhances the functionality of die fixtures but also opens new avenues for customization, leading to more efficient production strategies that align with the evolving demands of modern manufacturing environments.

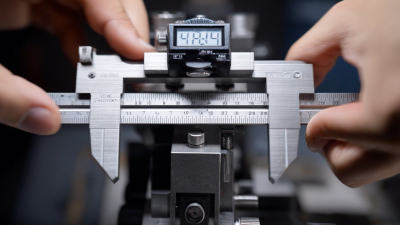

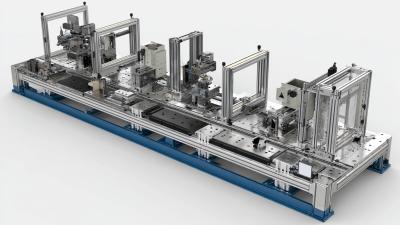

The integration of automation and smart technologies in die fixture production is transforming the manufacturing landscape by enhancing efficiency, precision, and flexibility. Automated systems streamline the setup and adjustment processes, significantly reducing human error and minimizing production downtime. With the advent of computer numerical control (CNC) machines, manufacturers can program intricate designs and achieve consistent results, leading to improved product quality. Furthermore, robotic solutions are increasingly being utilized to handle materials and perform repetitive tasks, allowing skilled workers to focus on more complex operations that require critical thinking and creativity.

Smart technologies, including the Internet of Things (IoT) and advanced data analytics, are also playing a crucial role in optimizing die fixture production. By connecting machinery and equipment, manufacturers can monitor their operations in real-time, enabling predictive maintenance that reduces the likelihood of costly breakdowns. Data analytics provide insights into production performance, allowing for better decision-making and resource allocation. As die fixture production evolves, the blend of automation and smart technologies will not only enhance operational efficiency but also support sustainable practices by minimizing waste and energy consumption. This shift signifies a pivotal moment in the industry, paving the way for more agile and responsive manufacturing processes in the years to come.

In recent years, sustainability has emerged as a pivotal focus in the development of die fixtures, significantly reshaping manufacturing practices. As we approach 2025, industry experts predict that sustainable practices will not only enhance operational efficiency but also align with growing environmental regulations. A recent report by the International Trade Administration indicates that 70% of manufacturers are actively integrating sustainability into their production processes, seeing it as a strategic imperative rather than an option. This shift is driven by both consumer demand for greener products and increasing scrutiny from governmental bodies.

The integration of sustainable materials in die fixture development has gained momentum, as manufacturers explore alternatives to traditional resources. According to a study published by the Manufacturing Institute, using recycled materials in production can reduce energy consumption by up to 30%. Moreover, advancements in additive manufacturing techniques enable designers to minimize material waste by optimizing the production process, resulting in fixtures that are not only more environmentally friendly but also more cost-effective. These innovations are paving the way for a new era in die fixture manufacturing, where sustainability is at the forefront of design and production strategies.

The die fixture industry is experiencing transformative innovations driven by key players who are reshaping the market landscape. Prominent manufacturers are investing in advanced materials and automation technologies that enhance efficiency and precision in die production. By implementing state-of-the-art machining processes and integrating smart technologies, companies are not only improving product quality but also reducing lead times, positioning themselves as leaders in a competitive market.

Moreover, collaboration among industry stakeholders is fostering an environment ripe for innovation. Strategic partnerships between technology providers and fixture manufacturers are yielding cutting-edge solutions that address the evolving needs in various applications. These alliances often focus on developing customizable and adaptive die fixtures that allow for greater flexibility in manufacturing processes, ultimately catering to the increasing demand for personalized production.

As die fixture innovations continue to emerge, market leaders are increasingly emphasizing sustainability. By adopting eco-friendly materials and efficient production methods, they are setting new standards that align with global sustainability goals. This commitment not only strengthens their brand reputation but also appeals to a growing segment of environmentally conscious customers looking for sustainable manufacturing solutions.

| Trend/Innovation | Description | Impact on Industry | Expected Growth (%) |

|---|---|---|---|

| Smart Die Fixtures | Integration of IoT and sensors for real-time data collection. | Enhanced efficiency and reduced downtime. | 25% |

| Modular Fixture Systems | Versatile systems that allow easy reconfiguration as per needs. | Increased adaptability and cost savings. | 20% |

| Advanced Materials | Use of lightweight but durable materials in die fixture manufacturing. | Improved longevity and performance. | 15% |

| Automation and Robotics | Integration of robotic systems for precision and efficiency. | Reduction in labor costs and increased production rates. | 30% |

| Sustainable Practices | Adoption of eco-friendly materials and processes. | Support for corporate responsibility and compliance with regulations. | 18% |