In the fast-paced world of auto repair, efficiency is key. Automotive fixtures play a pivotal role in enhancing that efficiency. These tools are more than just support; they shape workflows, ensuring repairs are done swiftly.

Properly utilizing automotive fixtures can save time and reduce frustration. However, not every shop fully optimizes their use. Sometimes, even the best fixtures sit unused because of neglect or lack of training. It’s crucial to regularly assess their effectiveness. Small adjustments can lead to significant improvements.

Adopting the right automotive fixtures must align with the specific needs of your workspace. Every shop is different, and what works in one may not work in another. Reflections on past practices can unveil potential pitfalls. Embracing a mindset of continuous improvement will maximize the benefit of these essential tools.

Automotive fixtures play a crucial role in auto repair shops. They provide the support and stability needed for repairs and maintenance. Well-designed fixtures can significantly enhance the efficiency of workflow. When tools are organized and accessible, technicians can focus more on the task at hand. However, many shops often neglect the importance of proper fixture maintenance. Broken or poorly designed fixtures can lead to delays and increased frustration.

Proper understanding of automotive fixtures means knowing what works best for your specific operations. For some, a simple tool bench suffices. Others might require specialized lifts or clamps. Observing how fixtures are used in daily tasks is vital. Every workspace has its unique challenges. Sometimes, it’s easy to overlook these needs until a project stalls. Identifying these pain points can lead to better fixture selection and usage.

Training staff on utilizing automotive fixtures effectively is equally important. Regularly scheduled maintenance checks can prevent small issues from ballooning. Technicians should feel empowered to suggest upgrades. They are the ones using the fixtures daily. Reflecting on these practices fosters a culture of continuous improvement. It can help reduce costs and increase productivity over time.

Efficient automotive repairs start with having the right tools. A well-organized workspace is just as crucial as the tools themselves. Consider using toolboxes that offer easy access to essential items. Magnetic trays can hold small parts securely and help prevent loss. Simple shelving can keep everything in its place and accessible.

Proper fixture setup also requires attention to detail. Ensure that your fixtures are adjustable for different vehicle types. Regularly inspect them for wear and tear. A faulty fixture can compromise safety and efficiency. Using quality materials for every fixture is vital, but cheap substitutes may tempt you. Don't overlook the small stuff; these components matter significantly.

Lastly, maximize workspace by eliminating clutter. Arrange tools in a way that provides a logical flow for repairs. This organization can save time during busy days. Reflecting on your setup frequently helps identify areas for improvement. An efficient workspace evolves with use, so remain open to change and adaptation.

Effective organization in an automotive workshop can dramatically improve repair efficiency. To achieve this, consider your fixture layout carefully. Each tool should be easily accessible. Time wasted searching for tools adds up quickly. Therefore, create designated areas for commonly used fixtures.

One effective tip is to utilize wall-mounted racks. This keeps tools off the workbench and visible. Magnetic strips can hold smaller metallic tools securely. However, clutter often happens. Regularly review and remove tools that you no longer use. It helps keep the space organized and functional.

Another practice is to label every drawer and container. Clear labeling minimizes confusion. It guides team members to find fixtures swiftly. Yet, the best layouts need revision over time. Workshop needs evolve as technology advances. Don't hesitate to adjust your organization system regularly based on practical experiences.

| Tip Number | Tip | Description | Benefits |

|---|---|---|---|

| 1 | Use Modular Fixtures | Implement modular fixtures to adapt to various repair tasks. | Increases flexibility and reduces setup time. |

| 2 | Label All Tools | Ensure all tools and fixtures are clearly labeled. | Reduces time searching for tools, improving efficiency. |

| 3 | Regular Maintenance | Schedule regular maintenance checks for your fixtures. | Prevents breakdowns and ensures consistent performance. |

| 4 | Create a Dedicated Storage Area | Allocate specific areas for storing automotive fixtures. | Organizes tools, reducing clutter and enhancing workflow. |

| 5 | Utilize Vertical Space | Maximize vertical storage for fixtures and tools. | Increases storage capacity without needing more floor space. |

| 6 | Implement Color-Coding | Use color codes for different types of tools and fixtures. | Facilitates quick identification and retrieval of tools. |

| 7 | Standardize Procedures | Develop standardized procedures for fixture usage. | Ensures consistent outcomes and improves training. |

| 8 | Keep Workstations Clean | Maintain cleanliness at each workstation. | Promotes safety and efficiency during repairs. |

| 9 | Invest in Quality Fixture Materials | Choose high-quality materials for your fixtures. | Ensures durability and reliability of fixtures during use. |

| 10 | Train Staff Regularly | Provide ongoing training for all staff on fixture usage. | Enhances skills and fosters a safe working environment. |

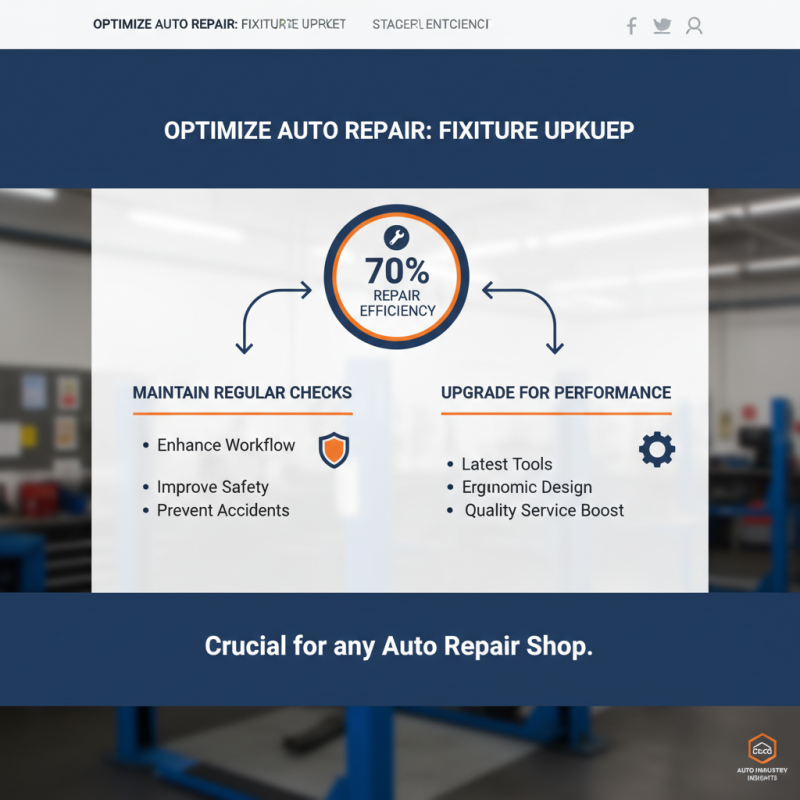

Maintaining and upgrading automotive fixtures is crucial for any auto repair shop. Proper fixtures can enhance workflow and improve safety. According to a recent industry report, 70% of repair efficiency depends on the quality of tools and fixtures. Regular checks are essential. Worn-out fixtures can lead to accidents and poor service quality.

Investing in high-quality, ergonomic fixtures pays off. Simple upgrades like better lighting can increase productivity by 35%. Keep your workspace organized. Clutter leads to mistakes and accidents. Utilize modular fixtures for flexibility. If fixtures gather dust, it’s time to analyze usage. Are they still effective?

Don’t overlook training staff on new fixtures. According to surveys, shops with well-trained teams see up to a 50% reduction in repair times. Regular feedback sessions encourage employees to voice concerns. This process helps in identifying which fixtures need maintenance or replacement. Effective communication can bridge gaps in understanding. Consider adding safety features where necessary. Safety should never be compromised. These changes require time and investment but yield significant benefits.

Safety is paramount when using automotive fixtures in any repair job. Proper setup is crucial for preventing accidents. Ensure that the fixture is stable and adequately secured before beginning work. An unstable fixture can lead to injuries or damage to the vehicle. Always double-check connections and support points. Neglecting this can result in serious consequences, especially in a busy shop environment.

Wearing appropriate personal protective equipment is essential. Safety goggles, gloves, and steel-toed boots create a barrier against potential hazards. Often, technicians overlook basic PPE, thinking they are safe without it. Realizing the risk is critical; a small oversight can lead to significant harm. Another aspect to consider is workspace organization. A cluttered area can make it difficult to maneuver safely. Regularly clean and organize your space to minimize hazards. Small changes can contribute to a safer repair process.