In the ever-evolving landscape of precision manufacturing, the integration of advanced holding fixtures has emerged as a pivotal factor in optimizing production efficiency. According to a recent report from the National Institute of Standards and Technology (NIST), manufacturers utilizing innovative holding fixtures can improve their machining accuracy by up to 30% and reduce cycle times by 15%. These improvements not only enhance product quality but also significantly lower operational costs, aligning with the increasing demand for both agility and precision in manufacturing processes.

As the global manufacturing sector continues to adapt to complexities posed by disruptive technologies and market fluctuations, leveraging innovative techniques for holding fixtures is essential. This introduction sets the stage to explore various strategies that can maximize the efficiency of holding fixtures in precision manufacturing, ensuring that organizations remain competitive in a challenging environment.

In the realm of precision manufacturing, the design of holding fixtures plays a crucial role in maximizing efficiency and ensuring product quality. Innovative design principles focus on customized solutions that accommodate various workpieces and machining processes. According to a recent report by the Manufacturing Institute, companies that implement advanced fixture designs can reduce setup time by up to 30%, significantly boosting overall productivity. This reflects the need for manufacturers to invest in tailored fixture solutions that align with their specific operational requirements.

In the realm of precision manufacturing, the design of holding fixtures plays a crucial role in maximizing efficiency and ensuring product quality. Innovative design principles focus on customized solutions that accommodate various workpieces and machining processes. According to a recent report by the Manufacturing Institute, companies that implement advanced fixture designs can reduce setup time by up to 30%, significantly boosting overall productivity. This reflects the need for manufacturers to invest in tailored fixture solutions that align with their specific operational requirements.

To achieve optimal performance, consider integrating modular fixture systems that allow for flexibility and rapid reconfiguration. These systems not only adapt to diverse workpieces but also minimize downtime during changeovers. Tips for implementation include conducting thorough feasibility studies to determine the best materials and configurations for your fixtures, as well as utilizing simulation software to anticipate and address any potential issues before production begins.

Additionally, employing data-driven methods to analyze fixture performance can lead to continual improvements. By regularly reviewing key performance indicators (KPIs), manufacturers can identify inefficiencies and make informed decisions to optimize their holding fixtures further. Regular training for the workforce on the latest techniques and fixture technologies can also play a pivotal role in maintaining high operational standards while ensuring safety and quality in precision manufacturing processes.

The integration of smart technology in precision manufacturing has revolutionized the way holding fixtures are utilized. Real-time monitoring systems now provide manufacturers with unprecedented insight into the performance and condition of these critical tools. According to a report from the Association for Manufacturing Technology (AMT), implementing smart monitoring solutions can increase equipment efficiency by up to 25%, while reducing downtime by approximately 30%. This is particularly vital in precision industries where even minor deviations can lead to significant errors and financial losses.

One innovative technique is leveraging IoT-enabled sensors that continuously track variables such as temperature, vibrations, and alignment. By analyzing this data in real-time, manufacturers can optimize their holding fixtures, ensuring that they consistently meet the necessary specifications. A study by Deloitte highlights that companies adopting these smart technologies can see a potential increase in overall productivity of 20% within the first year of implementation. This shift not only enhances operational efficiency but also fosters a proactive maintenance culture, reducing the risk of sudden failures and increasing the longevity of precision equipment.

This chart illustrates the efficiency improvements achieved by integrating smart technology for real-time monitoring of holding fixtures in precision manufacturing. The data reflects the percentage increase in production efficiency over a six-month period.

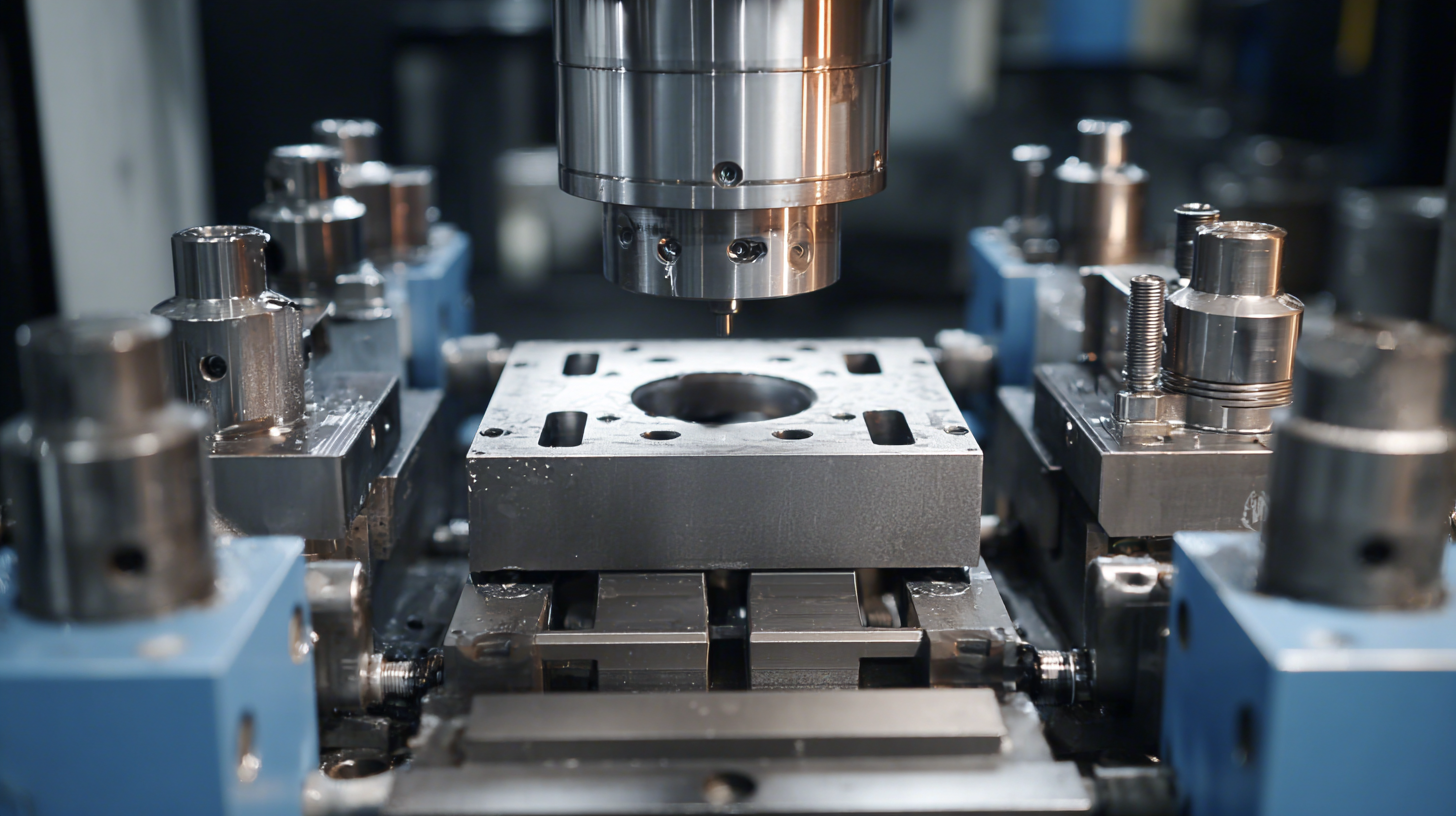

In precision manufacturing, the stability of workpieces is paramount to achieving optimal results. Recent studies indicate that nearly 30% of manufacturing faults can be traced back to inadequate fixture design, highlighting the critical role that advanced holding fixtures play in this industry. By employing innovative fixture configurations, manufacturers can significantly improve the precision of their machining processes, thereby enhancing the overall quality of the end product.

One effective technique involves utilizing modular fixtures that adapt to various workpiece geometries. This adaptability not only streamlines the setup process but also increases workpiece stability during machining, reducing the risk of vibrations that can lead to inaccuracies. According to a report by the American Society of Mechanical Engineers (ASME), implementing such advanced fixtures can increase throughput by up to 20%, allowing manufacturers to meet high-demand production schedules without compromising quality.

Furthermore, the integration of smart technologies in fixture design is transforming the landscape of precision manufacturing. Sensors embedded within fixtures can monitor real-time stability and alignment, allowing for immediate adjustments during production. A recent survey by the Precision Manufacturing Institute found that organizations utilizing such smart fixtures reported a 15% reduction in scrap rates, proving that investing in advanced holding fixture technology yields tangible benefits in efficiency and product reliability.

In precision manufacturing, the successful implementation of holding fixtures can dramatically enhance operational efficiency and accuracy. For instance, a leading aerospace manufacturer adopted a customizable fixture system that allowed rapid adjustments for various components. By integrating modular features, they minimized downtime usually associated with reconfiguration between production runs. The result was a 30% reduction in cycle times and a significant improvement in the quality of the machined parts, demonstrating how thoughtful fixture design can bolster productivity while maintaining precision.

Another case study highlights a medical device company that employed advanced 3D-printed fixtures for assembly tasks. These fixtures were tailored to the specific geometries required for various devices, ensuring consistent alignment and reducing the risk of human error during assembly. By utilizing these innovative fixtures, the company was able to achieve a higher throughput, decreasing production costs by 20% and enhancing the overall reliability of the assembled products. This example illustrates the transformative impact that tailored holding fixtures can have on precision manufacturing, ultimately driving success in highly competitive markets.

The landscape of precision manufacturing is rapidly shifting towards automation, particularly in the development and efficiency of holding fixtures. A report from MarketsandMarkets indicates that the global automation market is expected to reach $214 billion by 2026, with a CAGR of 9.2%. This growth is significantly impacting fixture design, as manufacturers increasingly integrate automated systems to enhance the precision and speed of production processes.

Automation facilitates the creation of adaptive fixtures that can be reconfigured on-the-fly, reducing downtime and enhancing productivity by up to 25%.

Moreover, advancements in robotics and AI-driven technologies are enabling real-time monitoring and adjustment of holding fixtures. According to a comprehensive study by Grand View Research, the integration of AI in manufacturing settings is projected to improve operational efficiency by up to 40%. Automated fixture systems equipped with sensors allow manufacturers to maintain optimal conditions throughout the production cycle, minimizing errors and reducing waste. As companies embrace these innovative techniques, the potential for increased efficiency in precision manufacturing becomes increasingly evident, paving the way for a more agile and responsive production environment.