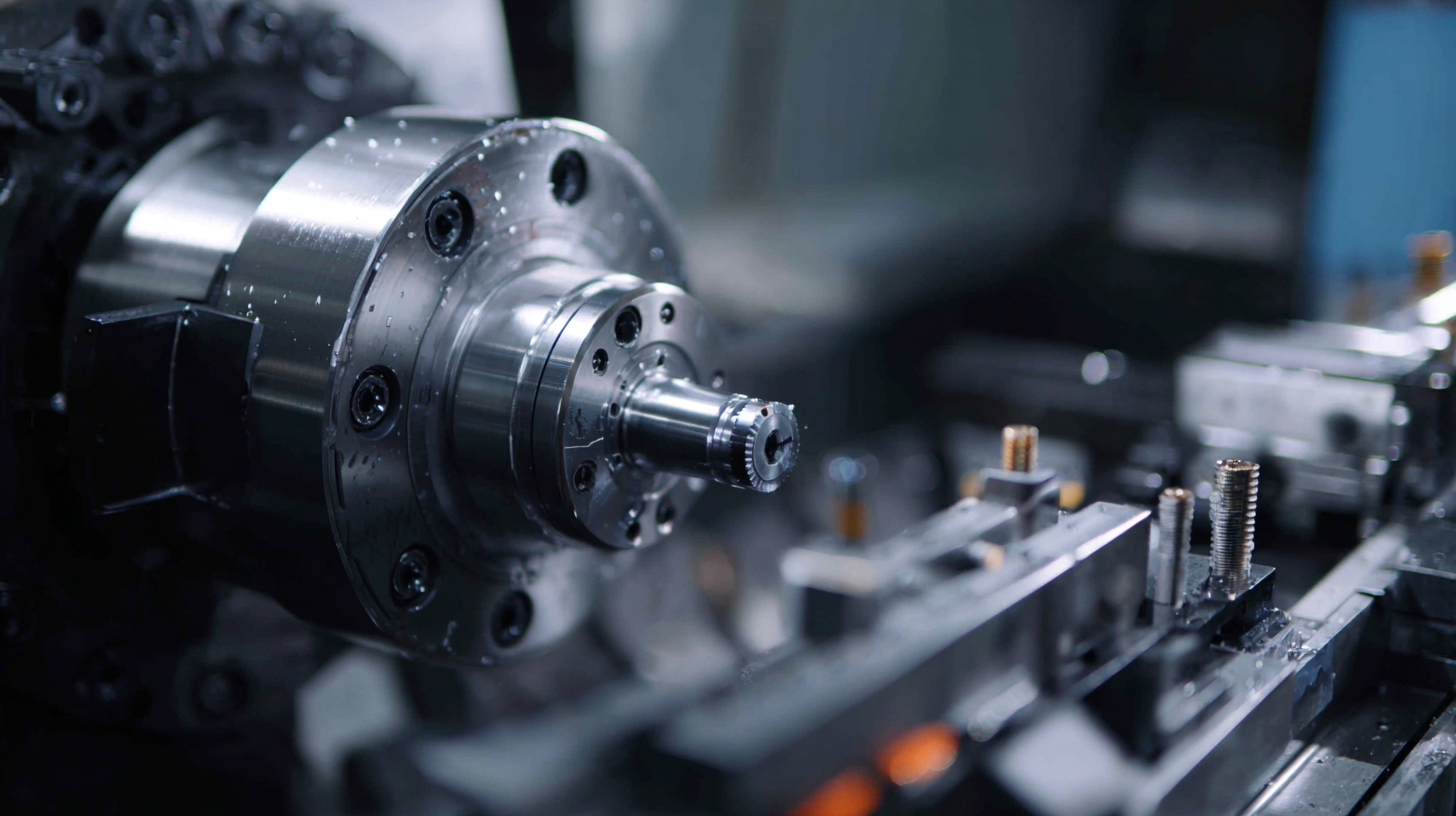

In the realm of modern manufacturing, efficiency and precision are paramount, and one critical element that contributes to achieving these goals is the CNC fixture. According to a report by the National Association of Manufacturers, optimizing production processes can lead to a 15% increase in productivity.

CNC fixtures play a pivotal role in this optimization by securely holding and accurately positioning workpieces during machining operations. A recent study by Deloitte indicates that advanced manufacturing technologies, including CNC fixtures, can reduce production time by up to 30%, significantly enhancing operational efficiency. As manufacturers strive to stay competitive in a rapidly evolving industry, understanding the importance of CNC fixtures is essential for anyone looking to innovate and improve their production workflows.

CNC fixtures play a pivotal role in this optimization by securely holding and accurately positioning workpieces during machining operations. A recent study by Deloitte indicates that advanced manufacturing technologies, including CNC fixtures, can reduce production time by up to 30%, significantly enhancing operational efficiency. As manufacturers strive to stay competitive in a rapidly evolving industry, understanding the importance of CNC fixtures is essential for anyone looking to innovate and improve their production workflows.

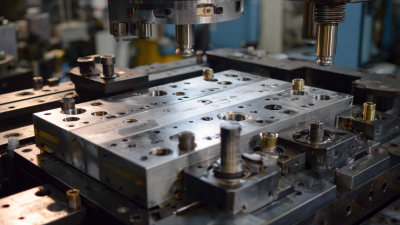

CNC fixtures play a crucial role in modern manufacturing by streamlining production efficiency and ensuring high precision in machining processes. According to a report by Grand View Research, the global CNC machine market is projected to reach $100 billion by 2025, driven by the increasing demand for automation and improved manufacturing accuracy. In this context, CNC fixtures serve as essential tools that hold workpieces in place, allowing for consistent repeatability and minimizing the risk of errors during fabrication.

The optimization of production lines through the implementation of CNC fixtures can significantly enhance throughput. A study by the National Institute of Standards and Technology (NIST) found that proper fixture design can reduce production time by up to 30%, which not only accelerates the manufacturing cycle but also lowers operational costs. By integrating advanced CNC fixture technologies, manufacturers can achieve tighter tolerances and better finish quality, leading to increased customer satisfaction and market competitiveness. This illustrates the indispensable nature of CNC fixtures in achieving efficient and reliable manufacturing processes in today’s fast-paced industrial landscape.

This chart illustrates the impact of CNC fixtures on production efficiency in various manufacturing processes. As demonstrated, the use of CNC fixtures significantly reduces production time and increases accuracy.

When designing effective CNC fixtures, there are several key considerations that can significantly enhance the overall manufacturing process. Firstly, precision is paramount. The fixture must hold the workpiece securely and align it perfectly with the CNC machine. This helps to minimize errors and ensures that the finished product meets the required specifications. Utilizing high-quality materials that resist wear and deformation is crucial in achieving this level of precision.

Another important aspect is the adaptability of the fixture. Manufacturing environments often require flexibility to accommodate different workpieces. Designing adjustable or modular fixtures can allow manufacturers to quickly switch between various projects without the need for extensive retooling. This adaptability not only saves time but also reduces costs associated with production downtime.

Tip: Always consider the ease of loading and unloading the workpiece when designing your CNC fixture. A well-designed fixture should streamline the setup process, allowing operators to efficiently position and secure parts with minimal effort.

Tip: Incorporate features that facilitate error detection and correction. Implementing indicators or guides can help operators quickly identify misalignments, ensuring that issues are addressed before the machining process begins, thus maintaining the quality of the output.

When selecting the right CNC fixture for your manufacturing processes, the first step is to assess your specific project requirements. Consider the dimensions and complexity of the parts you plan to produce. A thorough understanding of the material type and its characteristics is essential, as this will influence the type of fixture needed. Conducting a detailed analysis of the machining operations involved can help in determining the appropriate holding methods and tooling necessary to achieve precision.

Next, evaluate the fixture’s design and flexibility. A well-designed CNC fixture should accommodate various components and provide easy access for setup and adjustments. Look for designs that allow for quick changeovers when working with different parts, which can significantly reduce downtime and enhance productivity. Additionally, consider the manufacturing tolerances and how the fixture will maintain precise alignment during machining operations. Always consult with your engineering team to ensure compatibility with existing equipment, which will contribute to a more efficient manufacturing workflow.

In the realm of modern manufacturing, CNC fixtures play a crucial role in enhancing precision and efficiency. The choice of materials for these fixtures can significantly affect the overall performance and durability. Commonly used materials include aluminum, steel, and composite materials. According to a recent study by SME (Society of Manufacturing Engineers), aluminum is favored for its lightweight properties and excellent machinability, making it the primary choice for many lightweight fixtures. Steel, on the other hand, is popular for its strength and rigidity, ideal for heavy-duty applications.

When selecting materials for CNC fixtures, it is essential to consider the specific manufacturing environment and requirements. For instance, composite materials offer corrosion resistance and are suitable for environments exposed to chemicals, which can enhance the lifespan of the fixture.

Tip: Always assess the compatibility of the fixture material with the machining process to avoid unexpected wear or failure. Additionally, using a combination of materials can optimize costs and performance—aluminum bases with steel inserts, for example, can balance weight and strength effectively. Keeping abreast of industry trends and advancements in materials science will also help in making informed decisions for CNC fixture manufacturing.

CNC fixtures play a crucial role in modern manufacturing, ensuring precision and efficiency in the production process. To maintain and upgrade your CNC fixtures effectively, it is essential to adopt best practices that enhance their longevity and performance. Regular cleaning and inspection can prevent wear and tear, while periodic calibration ensures that the fixtures remain aligned and accurate, minimizing errors in machining operations.

In addition to routine maintenance, considering advancements in technology can significantly improve your fixtures. The rise of 3D printing in manufacturing allows for rapid prototyping and customization of jigs and fixtures, enabling quicker responses to production needs. Furthermore, high-density workholding techniques optimize machine time by maximizing the number of workpieces processed simultaneously. By integrating innovative solutions into your manufacturing processes, you can enhance productivity and maintain a competitive edge in the industry.

| Fixture Type | Material | Typical Applications | Maintenance Tips | Upgrade Recommendations |

|---|---|---|---|---|

| Modular Fixture | Aluminum | General machining, assembly | Regular cleaning, check alignment | Add quick change adapters |

| Dedicated Fixture | Steel | High-volume production | Inspect for wear and tear | Upgrade to automation features |

| Multi-Purpose Fixture | Composite materials | Varied machining operations | Lubricate moving parts | Incorporate sensor technology |

| Custom Fixture | Titanium | Precision components | Daily inspection, cleaning | Review design for efficiency |