In the rapidly evolving landscape of modern manufacturing, the role of the best assembly fixture has become increasingly pivotal, serving as a backbone for efficiency and quality assurance. According to a report by Grand View Research, the global assembly fixtures market is anticipated to reach USD 5.69 billion by 2025, driven by the growing demand for automation and precision in production processes. Assembly fixtures not only streamline workflows but also reduce error rates significantly, with studies showing that efficient fixture designs can cut assembly time by up to 30%. As manufacturers strive for enhanced competitiveness, understanding the importance of selecting the right assembly fixture is essential for optimizing operational performance and ensuring product integrity. This blog explores the various types of assembly fixtures available and their comparative advantages in modern manufacturing practices.

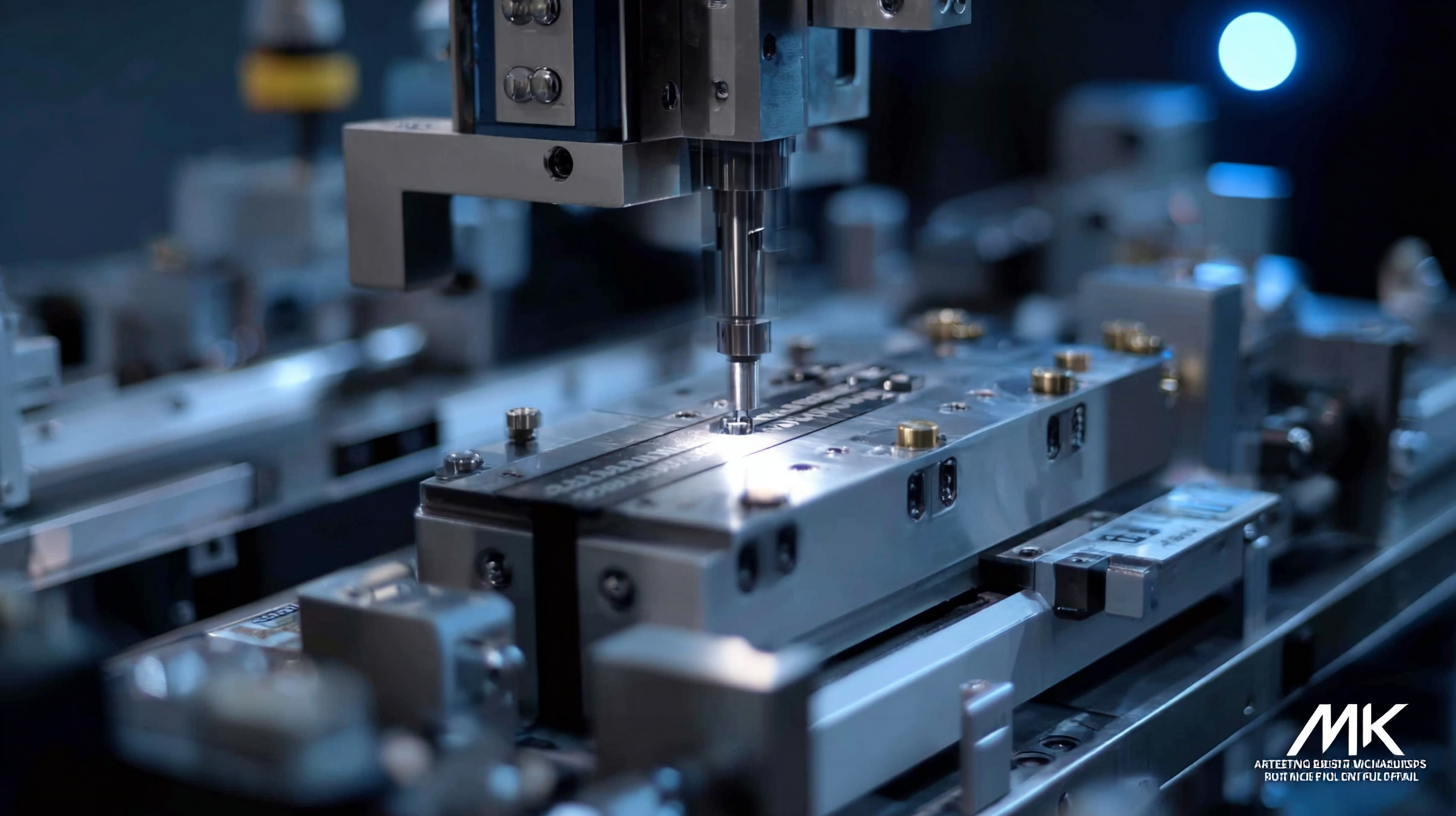

In modern manufacturing, the efficiency of production processes is crucial for maintaining competitiveness in the market. Assembly fixtures play a pivotal role in enhancing this efficiency by streamlining the assembly process. These specialized tools help to securely hold and position components, ensuring accuracy and consistency in manufacturing. By minimizing errors and reducing the time taken for assembly tasks, manufacturers can dramatically improve their output.

When designing assembly fixtures, it’s essential to consider the following tips for maximizing efficiency. First, focus on modular design, allowing fixtures to be easily adapted for different projects or products. This flexibility can significantly reduce setup time. Second, ensure that the fixtures are ergonomically designed to facilitate operator comfort, which can lead to higher productivity and lower fatigue levels. Additionally, incorporating automation technology can enhance precision and speed even further, making the assembly process not only faster but also more reliable.

Investing in high-quality assembly fixtures is a strategic decision that manufacturers should not overlook. By optimizing the assembly process, companies can achieve higher throughput and maintain a competitive edge in an increasingly demanding market.

In today's competitive manufacturing landscape, the role of high-quality assembly fixtures cannot be overstated. These fixtures are crucial in streamlining production processes, ensuring that parts are aligned and secured accurately during assembly. One of the key benefits of using top-tier fixtures is the significant reduction in production errors. When components are consistently held in the correct position, the likelihood of mistakes decreases, leading to higher-quality end products and improved customer satisfaction.

Moreover, high-quality fixtures enhance the efficiency of production lines. They allow for faster assembly times by simplifying the setup process and minimizing the need for constant adjustments. This efficiency translates to increased output, enabling manufacturers to meet market demands swiftly. Additionally, investment in durable fixtures reduces long-term costs; while they may require a higher upfront investment, their longevity and reliability can lead to substantial savings over time by reducing downtime and maintenance needs. Thus, the adoption of superior assembly fixtures is a strategic move that can provide an edge in an ever-evolving industry.

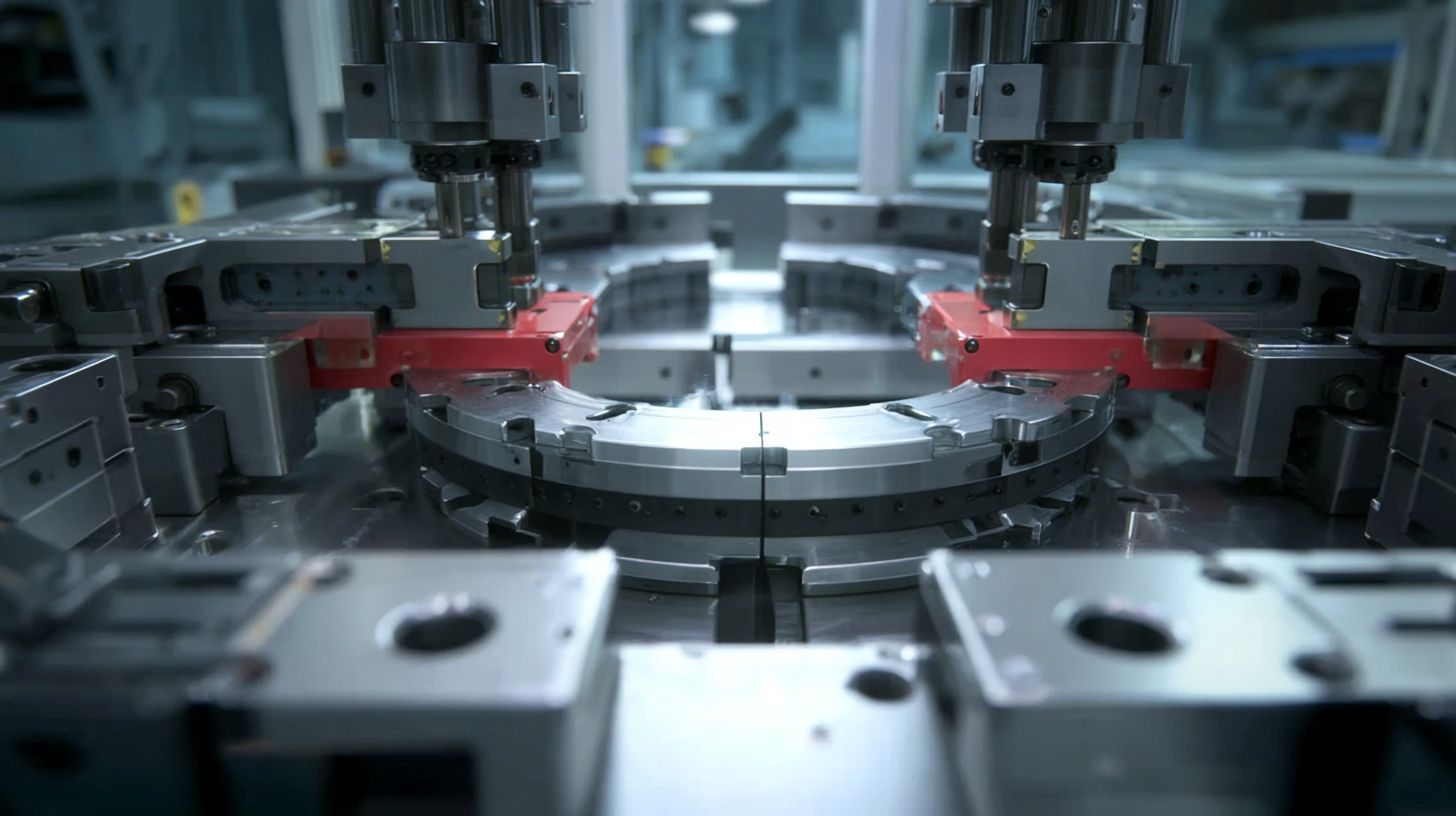

In the evolving landscape of modern manufacturing, the role of innovative assembly fixtures has never been more critical. These vital tools not only improve efficiency but also enhance the overall quality of production processes. As industries increasingly embrace automation and advanced manufacturing techniques, assembly fixtures are being designed with flexibility and scalability in mind. This adaptability allows manufacturers to respond swiftly to changing market demands, fostering a culture of innovation that is essential for staying competitive.

According to recent industry reports, the Aircraft Lavatory System Market is expected to grow significantly, with projections indicating an increase from $679.86 million in 2025 to $1,088.50 million by 2032, reflecting a CAGR of 7.0%. This growth underscores the rising importance of precision-engineered assembly fixtures in producing complex components like those found in the aerospace sector. By integrating cutting-edge technology into fixture design, manufacturers can significantly reduce assembly time and improve accuracy, which is especially crucial in high-stakes environments like automotive and aerospace manufacturing.

As creativity drives innovation, the automotive manufacturing landscape increasingly relies on advanced assembly fixtures to optimize production processes. The ability to create fixtures that support rapid prototyping and efficient assembly processes is essential for meeting the demands of modern consumers. This synergy between fixture design and production efficiency serves as a catalyst for innovation, demonstrating how vital these tools are to shaping the future of manufacturing.

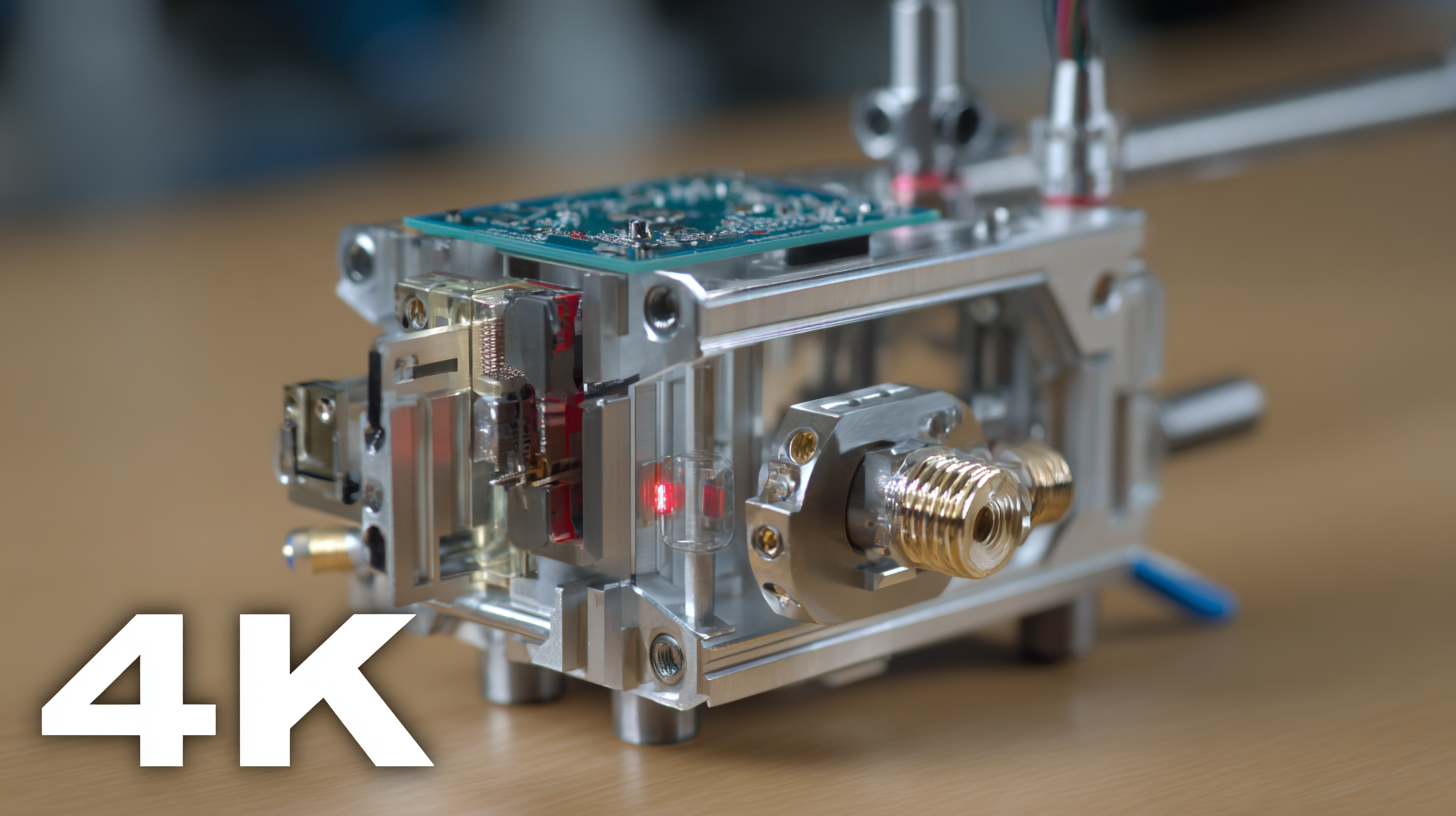

In the realm of modern manufacturing, the implementation of high-quality assembly fixtures has proven to be a game-changer, as evidenced by various success stories from China. Companies that have embraced advanced fixture technology not only streamline their production processes but also enhance overall product quality. For instance, a major electronics manufacturer in Shenzhen reported a 30% increase in assembly speed after deploying custom fixtures that minimized manual handling and errors. This highlights the critical role of assembly fixtures in optimizing workflow and improving efficiency.

Tips for selecting the right assembly fixture include assessing the specific needs of the manufacturing process and considering the materials used in the fixtures. Factors such as durability, ease of adjustment, and compatibility with different product types can significantly impact production outcomes. Additionally, continuous feedback loops from assembly line workers can inform fixture design improvements, ensuring that tools evolve alongside manufacturing processes.

Another compelling example comes from the automotive industry, where a leading car manufacturer implemented modular fixtures that allow for quick reconfiguration to accommodate different vehicle models. This adaptability not only saves time but also increases versatility in production capabilities. By investing in the right fixture solutions, manufacturers can enhance productivity while staying agile in response to market demands.

The rapid integration of automation technologies in modern manufacturing is reshaping the landscape of assembly fixtures. As industries adopt advanced robotics and automation, the evolution of assembly fixtures has become critical to ensuring precision and efficiency. Current forecasts indicate that the assembly fixture market is projected to reach $6.1 billion by 2026, growing at a CAGR of 5.3%, driven by the rising demand for customized automation solutions. This growth is necessary to support enhanced production capabilities, particularly in sectors like aerospace where automation is becoming increasingly prevalent.

However, the implementation of robotics in aviation manufacturing reveals emerging challenges that highlight the importance of optimized assembly fixtures. Recent developments indicate that automation processes still suffer from low levels of operational planning automation and collision detection systems. This lack of advanced functionalities can significantly impact production timelines and quality. As the industry aims to improve these shortcomings, the demand for state-of-the-art assembly fixtures becomes even more evident, ensuring that robotic systems can operate seamlessly and safely within complex manufacturing environments. With improved fixture designs, manufacturers can mitigate risks associated with manual programming and positioning, thereby enhancing overall operational efficiency.