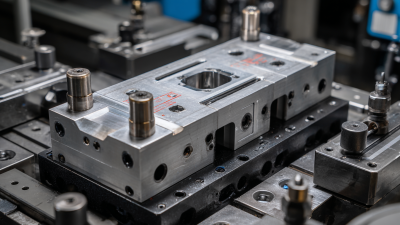

In the rapidly evolving landscape of manufacturing, the role of Engineering Fixtures has become increasingly critical in shaping efficiency and quality. These specialized tools are essential for securing and supporting components during production processes, ensuring precision and consistency in every manufactured part. As manufacturers strive to meet higher demands for quality and speed, understanding the impact of engineering fixtures on operational performance is vital. This guide will explore the various types of engineering fixtures and their contributions to optimizing manufacturing workflows. By delving into the intricacies of design and implementation, we aim to highlight best practices that can enhance production capabilities and ultimately lead to superior product outcomes. Whether you're a seasoned engineer or new to the field, this exploration will provide valuable insights into leveraging engineering fixtures for maximum manufacturing effectiveness.

Engineering fixtures play a crucial role in enhancing manufacturing processes by providing stability and precision during production. These tools not only streamline operations but also ensure that each component is manufactured to the highest standards. By integrating fixtures into the workflow, manufacturers can reduce setup times and minimize errors, leading to significant efficiencies in both time and cost.

**Tip 1:** Optimize fixture design by utilizing modular components that can be easily adjusted or replaced. This flexibility allows for quick adaptations to different manufacturing tasks without extensive downtime, ultimately improving overall throughput.

Moreover, effective engineering fixtures contribute to maintaining consistent quality throughout the production cycle. With fixtures tailored to specific tasks, workers can achieve higher accuracy and repeatability, reducing defects and rework. This fosters a culture of quality assurance that permeates the entire manufacturing process.

**Tip 2:** Regularly review and update fixtures based on production feedback. Engaging with operators and engineers to assess fixture performance can lead to valuable insights, allowing for continuous improvement and increased efficiency.

| Fixture Type | Impact on Efficiency (%) | Reduction in Error Rate (%) | Setup Time (minutes) | Cost Savings ($) |

|---|---|---|---|---|

| Hydraulic Fixtures | 25% | 30% | 15 | 2000 |

| Mechanical Fixtures | 18% | 25% | 20 | 1500 |

| Custom Tooling Fixtures | 30% | 40% | 10 | 3000 |

| Electromagnetic Fixtures | 22% | 35% | 12 | 2500 |

| Modular Fixtures | 15% | 20% | 25 | 1000 |

In the competitive landscape of manufacturing, the design and implementation of engineering fixtures play a pivotal role in enhancing efficiency and ensuring product quality. Recent statistical analyses indicate that optimizing fixture design can reduce production time by up to 30%. This significant improvement is especially evident in industries like biopharmaceutical manufacturing, where the application of Lean Six Sigma methodologies has demonstrated that targeted adjustments to fixtures can streamline workflows and minimize waste.

To achieve these efficiency gains, manufacturers should consider the following tips: First, engage in a thorough analysis of current fixture designs using data-driven approaches like DMAIC (Define, Measure, Analyze, Improve, Control) to identify potential areas of waste. Second, involve cross-functional teams in the design process to leverage diverse perspectives and expertise, ensuring that fixtures meet operational needs while enhancing user experience. Lastly, regularly review and optimize fixtures as part of the continuous improvement cycle to adapt to changing production requirements and technologies.

By focusing on precise fixture design, manufacturers can not only achieve remarkable reductions in cycle time but also significantly improve overall product quality, leading to enhanced customer satisfaction and long-term success.

In the realm of manufacturing, engineering fixtures play a critical role in enhancing product consistency and reducing defect rates. According to a report by the American Society of Mechanical Engineers, implementing well-designed fixtures can improve manufacturing efficiency by up to 30%, while simultaneously decreasing defects by nearly 20%. These statistics underscore the importance of quality assurance practices tied to fixture design, which can directly influence a company's bottom line.

In the realm of manufacturing, engineering fixtures play a critical role in enhancing product consistency and reducing defect rates. According to a report by the American Society of Mechanical Engineers, implementing well-designed fixtures can improve manufacturing efficiency by up to 30%, while simultaneously decreasing defects by nearly 20%. These statistics underscore the importance of quality assurance practices tied to fixture design, which can directly influence a company's bottom line.

One key factor in achieving high product consistency is ensuring precise alignment and stable support during the manufacturing process. This leads to uniformity in product dimensions and functionality. In fact, a study by the Institute of Industrial Engineers reports that organizations investing in advanced fixture technology experience a 15% increase in product consistency compared to their traditional counterparts.

Tips for manufacturers: First, invest in adjustable fixtures that can accommodate variations in parts without compromising on precision. This adaptability not only enhances quality but also extends the life of the fixtures. Second, regularly assess and calibrate fixtures to maintain their performance; a consistent check-up schedule could lead to a significant reduction in defect rates. By prioritizing these strategies, manufacturers can ensure better quality products while optimizing their operations.

In recent years, leading manufacturing firms have adopted engineering fixtures to enhance both efficiency and quality in their production processes. A case study from a top automotive manufacturer showcased the implementation of specialized jigs that reduced assembly time by 30%. By customizing fixtures to fit specific parts, workers can achieve greater precision and ensure that assemblies are done consistently, leading to fewer defects and higher throughput.

One essential tip for successful implementation is to involve team members from the outset. Engaging operators in the design phase allows their expertise and insights to inform fixture development, ensuring that the final product meets practical needs on the shop floor. Additionally, businesses should invest in training to ensure all personnel are proficient in using the new fixtures, as this can significantly minimize errors during production.

Another noteworthy case comes from a medical device manufacturer that reinvented its fixture design to streamline quality control processes. By integrating measurement tools directly into the fixtures, they were able to conduct real-time inspections, reducing rework and improving overall product reliability. Regularly reviewing fixture performance and making necessary adjustments is crucial for maintaining their effectiveness and ensuring continued improvements in manufacturing processes.

This chart illustrates the correlation between the implementation of engineering fixtures and improvements in manufacturing efficiency and product quality across various dimensions in leading manufacturing firms.

In today’s manufacturing landscape, the design of engineering fixtures plays a critical role in bolstering both worker safety and operational productivity. Research from the National Institute of Standards and Technology (NIST) highlights that well-designed fixtures can decrease assembly time by up to 20%. This efficiency not only enhances throughput but also minimizes the risk of workplace accidents. A well-structured fixture ensures that components are securely positioned, reducing the likelihood of errors that can lead to injuries or product defects.

Moreover, adopting best practices in fixture design, such as incorporating ergonomic principles, can significantly impact worker safety. A report from the Occupational Safety and Health Administration (OSHA) indicates that ergonomically designed workstations can reduce musculoskeletal disorders (MSDs) by 30%. By focusing on employee comfort and efficiency, manufacturers can foster a safer work environment, which in turn improves overall morale and productivity. For instance, the incorporation of adjustable fixtures allows workers to operate at optimal heights and angles, thus reducing strain and fatigue.

Ultimately, investing in smart fixture design is not just a matter of enhancing productivity; it’s a crucial strategy for promoting a culture of safety within manufacturing operations. By leveraging data-driven approaches and prioritizing ergonomic solutions, companies can optimize their processes while safeguarding their workforce.