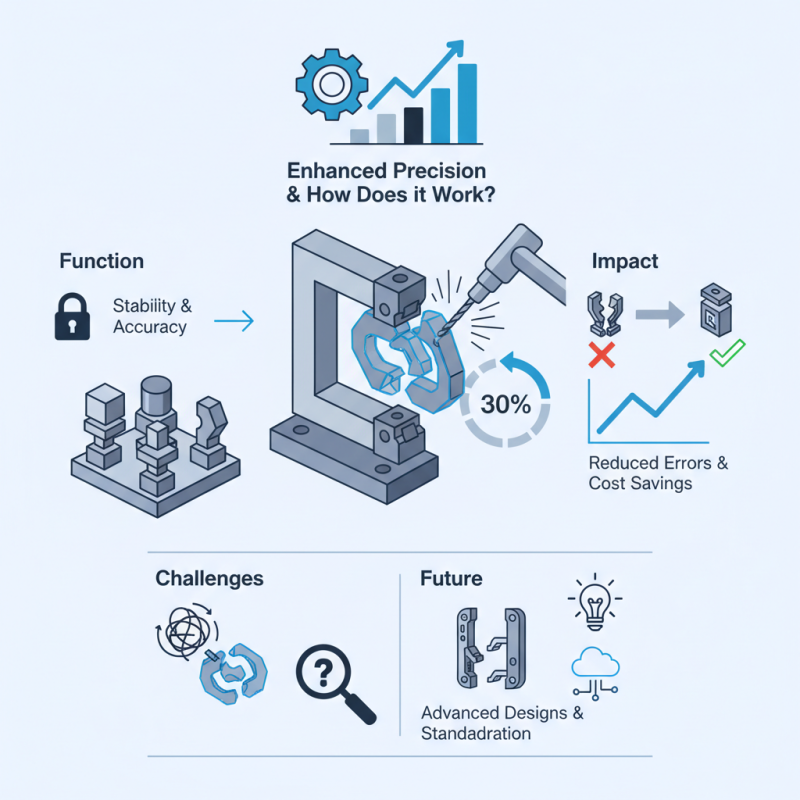

In the manufacturing sector, holding fixtures play a crucial role in enhancing precision and efficiency. According to a recent report by the International Organization for Standardization (ISO), effective holding fixtures can increase machining accuracy by up to 30%. This is vital in industries where even minor deviations can lead to significant product failures.

Holding fixtures are devices designed to securely hold parts during various machining processes. They ensure stability, allowing tools to operate with high precision. However, many organizations still overlook their importance. In some cases, improperly designed fixtures may lead to misalignment, resulting in costly errors.

As the demand for high-quality products continues to rise, the role of holding fixtures becomes more pivotal. Companies must invest in advanced designs and materials. The industry also faces challenges in standardization. Many manufacturers are unaware of the potential enhancements that well-engineered holding fixtures can bring. Awareness is key to improving overall production outcomes.

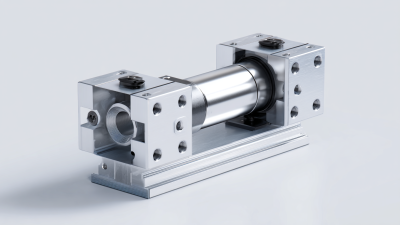

A holding fixture is a vital tool used in manufacturing and assembly processes.

It securely holds parts in place, allowing for precision during operations. This helps in tasks like machining, welding, and assembly.

By stabilizing components, holding fixtures ensure that every cut, weld, or screw is applied accurately.

A well-designed fixture can significantly enhance efficiency.

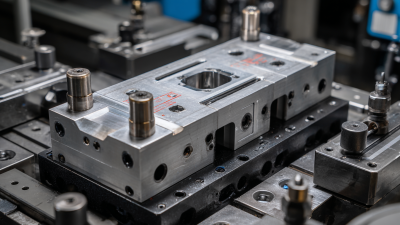

The design of a holding fixture often requires careful consideration.

It must fit the part perfectly yet be easy to use.

Materials like metal or durable plastic are common.

However, imperfections can occur. A fixture might not align perfectly, leading to issues.

Even small shifts during a process can affect the final product's quality.

It's always essential to test and adjust fixtures to meet specific needs.

While holding fixtures offer advantages, they also have limitations.

Changing part designs might require new fixtures, adding costs.

Operators need training to use them effectively.

Not all fixtures are created equal, so evaluating their effectiveness is crucial.

Overall, a well-thought-out holding fixture can make a significant difference in manufacturing processes,

enhancing both quality and productivity.

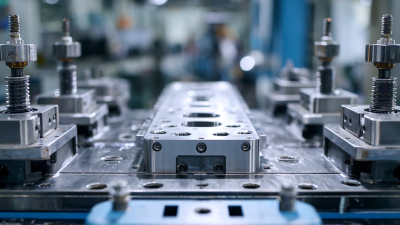

Holding fixtures play a crucial role in various manufacturing processes. Their primary purpose is to securely position and hold workpieces during operations like machining, welding, or assembly. This stability enhances precision and reduces the risk of errors. According to a recent industry report, about 75% of manufacturers reported improvements in output quality after implementing effective holding fixtures.

In terms of functionality, these fixtures must cater to diverse shapes and sizes of workpieces. They should be adaptable to different projects. Some reports indicate that improper fixture setups can lead to a significant drop in efficiency—up to 30%. This underscores the need for careful fixture design to accommodate specific machining or assembly tasks.

However, challenges persist in fixture design and implementation. Designers often face difficulties in balancing cost with functionality. A study highlighted that 40% of manufacturers feel their current fixtures do not fully meet their needs. This gap emphasizes the importance of iterative design and testing, ensuring that holding fixtures are both effective and adaptable to changes in production demands.

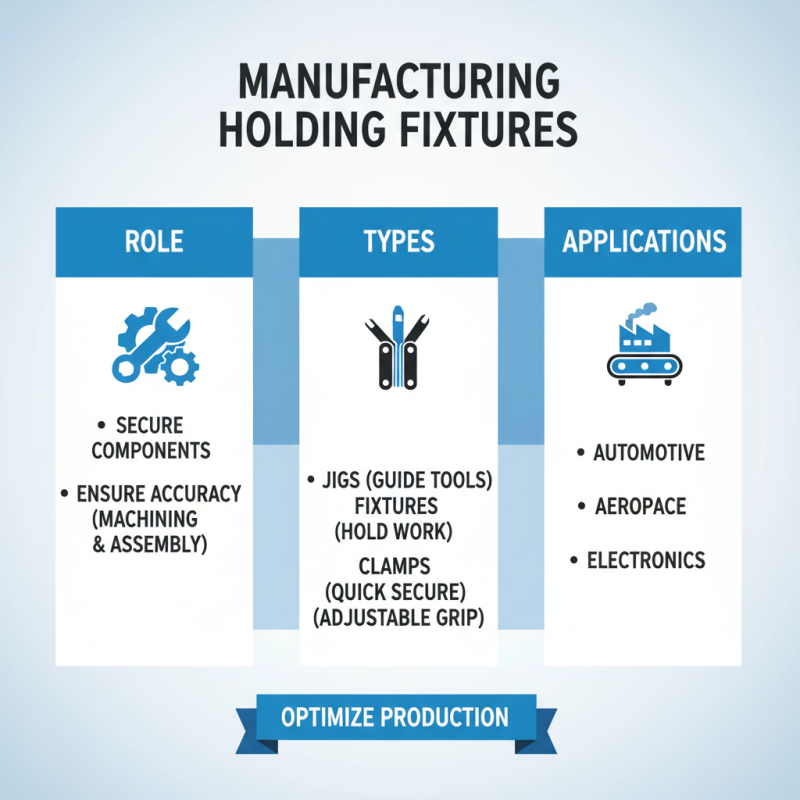

Holding fixtures play a vital role in various manufacturing processes. They secure components in place, ensuring accuracy during machining and assembly. Several types of holding fixtures exist, each designed for specific applications.

One common type is the locational fixture. It aids in positioning parts accurately for machining. These fixtures can be customized to fit different shapes and sizes. For instance, a fixture for a flat metal sheet might not work for a cylindrical object. This highlights the importance of choosing the right fixture for each task.

Another type is the assembly fixture. These are crucial in tasks like welding or fastening. They help align components, making assembly easier and reducing errors. However, they can be complex and require adjustments over time. The need for regular maintenance often gets overlooked, leading to misalignment issues. Proper setup and periodic checks are essential to maximize their effectiveness.

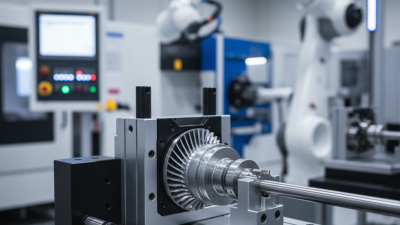

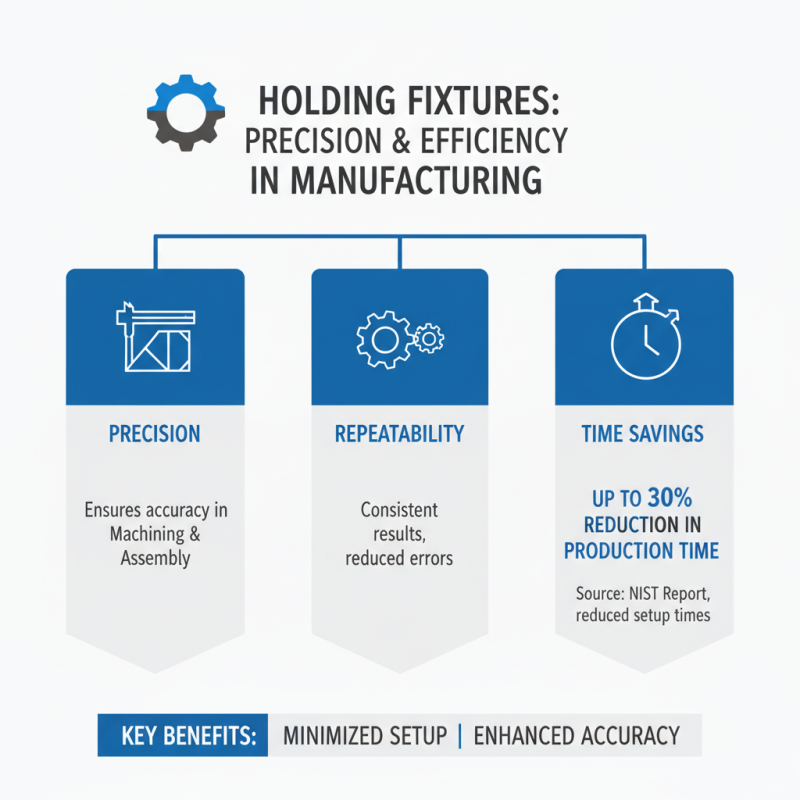

Holding fixtures play a crucial role in modern manufacturing. They ensure precision and repeatability in processes such as machining and assembling. According to a recent report by the National Institute of Standards and Technology (NIST), implementing holding fixtures can reduce production time by up to 30%. This efficiency stems from minimizing setup times and enhancing the accuracy of operations.

With improved accuracy, manufacturers can expect higher product quality. A survey from the American Society of Mechanical Engineers (ASME) revealed that companies using advanced holding fixtures experienced a 25% drop in defect rates. Mistakes often happen during setup, leading to costly reworks. Minimizing these errors contributes significantly to overall efficiency.

However, challenges exist. Not all fixtures are versatile enough for multiple operations. Companies occasionally invest heavily in custom fixtures but then face limitations. The need for regular maintenance and calibration can disrupt workflows. Therefore, while holding fixtures enhance efficiency, their design and upkeep require careful consideration. Balancing these factors is essential for sustained manufacturing success.

When designing and using holding fixtures, clarity is crucial. Choose materials that can withstand pressure and maintain precision. Common materials include aluminum or steel, depending on the required strength. Design your fixtures to allow easy access to the workpiece. This avoids frustration and improves efficiency during assembly and disassembly.

Consider removable components. They can help adapt the fixture to different tasks. However, ensure they are robust enough to maintain alignment. Regularly assess your fixtures for wear and potential failure points. A small crack can lead to significant errors.

Monitoring the setup is essential. Occasionally, a fixture might not hold correctly, leading to variation in the final product. It’s crucial to document processes and outcomes. This can help identify trends and areas for improvement. Engaging your team in these reflections enhances the design process. Collaboration often sparks new ideas and solutions.