In the precision-driven world of measurement and manufacturing, accuracy is paramount. A Gauge Checker serves as an essential tool for professionals and hobbyists alike, ensuring that measurements are not only consistent but also reliable. Whether you are in a high-stakes industrial setting or working on personal projects, the ability to measure accurately can significantly influence the outcome. Understanding how to effectively use a Gauge Checker can elevate your work, enabling you to identify discrepancies and maintain quality standards.

This guide provides a step-by-step approach to mastering the use of a Gauge Checker, equipping you with the knowledge necessary to achieve precise measurements. We will explore the key features of a Gauge Checker, the proper techniques for its application, and the common pitfalls to avoid. By following these guidelines, you can enhance your measurement processes, ultimately leading to better results in your projects. Join us as we delve into the world of gauge checking, where accuracy meets reliability, and every measurement counts.

Gauge checkers are essential tools in various industries, designed to ensure accurate measurements and validate the performance of measuring instruments. Understanding the purpose of these devices is critical for anyone involved in quality control, production, or any field where precision is paramount. Essentially, gauge checkers help identify if a measurement tool is functioning correctly, allowing users to maintain standards and avoid discrepancies in measurements that could lead to costly errors.

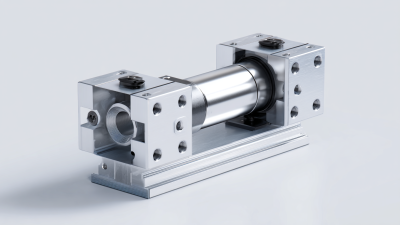

There are several types of gauge checkers, each serving a specific function based on the measurement context. Some common types include dial indicators, optical comparators, and electronic gauge checkers. Dial indicators provide precise readings on dimensional measurements, while optical comparators project a magnified silhouette of the measurement parts for visual inspection. Electronic gauge checkers often feature digital displays for easier reading and can provide more advanced features like data logging. By choosing the right type of gauge checker, users can enhance the reliability of their measurement processes and ensure consistent output quality.

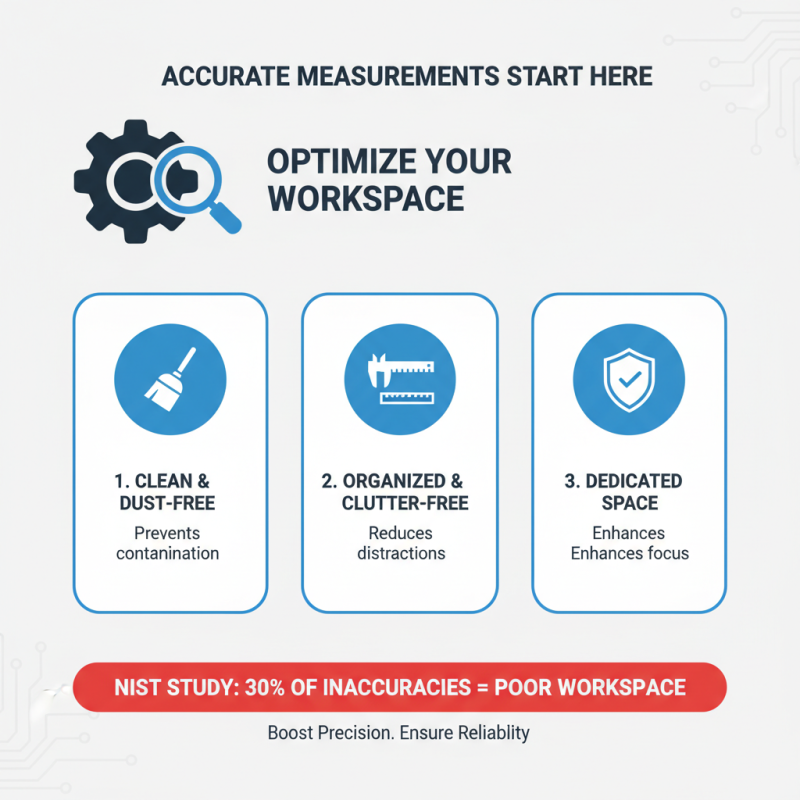

Preparing your workspace for accurate measurement tasks is crucial for achieving reliable results, especially when using instruments like gauge checkers. A clean and organized environment minimizes distractions and reduces the potential for errors during measurement. According to a study by the National Institute of Standards and Technology (NIST), nearly 30% of measurement inaccuracies can be traced back to poor workspace conditions. Therefore, ensuring that your workspace is free from clutter, dust, and unnecessary items can significantly enhance the precision of your measurements.

Proper lighting is another vital aspect of workspace preparation. Insufficient lighting can lead to misinterpretation of measurement readings and increase the likelihood of mistakes during the gauge checking process. The Illuminating Engineering Society (IES) recommends specific lighting levels for different measurement tasks; for instance, a minimum of 300 lux is suggested for most technical applications to ensure that operators can clearly see and interpret measurement scales. Additionally, ergonomic arrangements of tools and measurement devices can facilitate smoother workflows, enabling more accurate and efficient measurements while reducing physical strain on the user. By being mindful of these workspace considerations, professionals can greatly improve the reliability and accuracy of their measurement tasks.

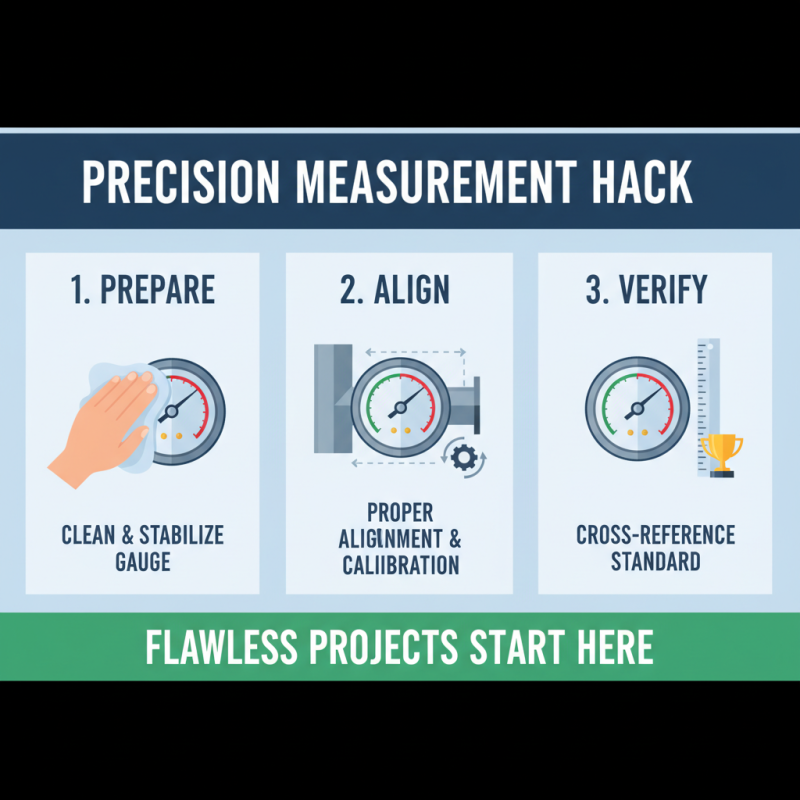

Using a gauge checker can significantly enhance the accuracy of your measurements, ensuring that your projects are executed flawlessly. To begin, place the gauge on a stable surface and ensure it is clean and free from debris. This is crucial because any dirt or oil can skew your measurement results. Next, align the gauge with the item you are measuring, making sure that it is properly calibrated. A good practice is to reference a known standard measurement to verify the gauge's accuracy before proceeding further.

Tips: Always check the calibration of your gauge before each use, especially if it has been subjected to rough handling. Additionally, take multiple readings at different points on the object being measured. This will help identify any inconsistencies and provide a more comprehensive view of your measurements.

Once you have taken your readings, interpret the results carefully. If you notice any discrepancies, consider revisiting the alignment or re-calibrating your gauge. For best results, document your measurements and the conditions under which they were taken. This record can be invaluable for future projects or troubleshooting potential issues.

When utilizing a gauge checker, precision is paramount; however, several common mistakes can undermine measurement accuracy. One prevalent error is improper calibration. Research from the National Institute of Standards and Technology (NIST) indicates that a miscalibrated gauge can lead to measurement deviations of up to 5%, which can significantly impact quality control in manufacturing processes. Therefore, it's essential to regularly verify and recalibrate gauge checkers according to manufacturer guidelines.

Another frequent mistake is neglecting environmental factors that can affect measurements, such as temperature and humidity. According to a report from the American Society for Quality (ASQ), fluctuations in these environmental conditions can introduce variability into measurements, potentially skewing results. Users are advised to conduct measurements in a controlled environment to mitigate these effects and ensure reliable readings.

Furthermore, not allowing the gauge checker to acclimate to the measurement environment can also result in inaccurate assessments, potentially causing costly errors in production lines.

Maintaining and calibrating your gauge checker is essential for ensuring accurate measurements and prolonging the tool's lifespan. According to a report by the National Institute of Standards and Technology (NIST), regular calibration can improve measurement accuracy by up to 20%. A critical aspect of this process is to ensure that the gauge checker is inspected for wear and tear, as accumulated dirt or mechanical wear can lead to significant measurement errors. Ideally, gauge checkers should be calibrated at least once a year, or more frequently if they are used in high-demand environments.

To properly maintain a gauge checker, clean it after each use with a suitable cleaning agent to prevent the build-up of contaminants. Furthermore, it is vital to store the gauge checker in a controlled environment, minimizing exposure to extreme temperatures and humidity, which can affect its precision. The American Society for Quality (ASQ) emphasizes the impact of environmental conditions, stating that fluctuations in temperature can lead to a variance of up to 0.1% in measurement readings. Implementing a routine maintenance schedule not only ensures longevity but also enhances reliability, thereby safeguarding the integrity of your measurement processes in various applications, including manufacturing, construction, and engineering industries.