Choosing the right automotive fixtures for your workshop is crucial for efficiency and safety. Industry expert John Smith emphasizes, "Quality fixtures make all the difference in a busy shop." His words highlight the importance of investing time and effort into selecting the most suitable tools.

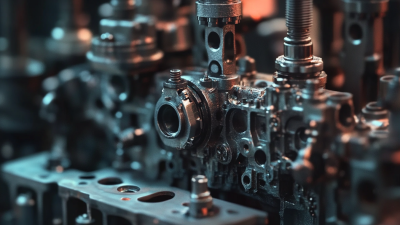

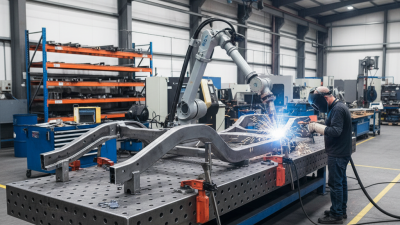

Automotive fixtures encompass various types of devices essential for repair and maintenance tasks. You’ll find alignment jigs, welding fixtures, and various holding devices in a modern workshop. Each type serves a specific purpose, enhancing productivity. However, many shop owners overlook this aspect, leading to inefficiencies. It’s essential to understand the specific needs of your workshop before making decisions.

Selecting the right automotive fixtures can be challenging. Poor choices often result in frustration and delays. Reflect on what your workshop requires. Analyze the tasks performed regularly. Consider both the short-term and long-term needs. A well-thought-out investment pays off, but it takes effort to identify the optimal solutions.

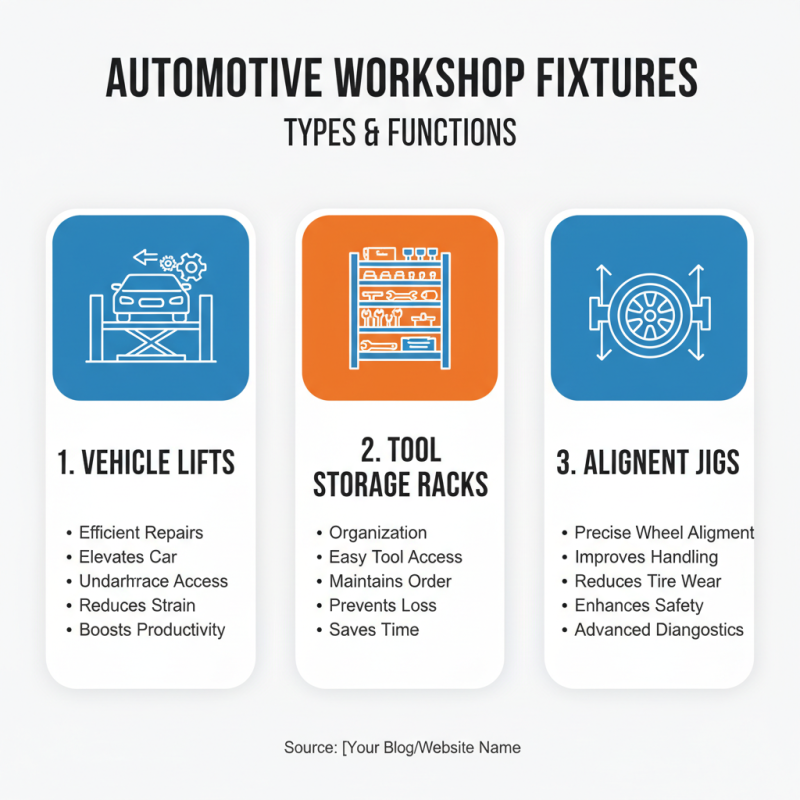

When selecting automotive fixtures for your workshop, it’s crucial to understand their types and functions. Common fixtures include vehicle lifts, tool storage racks, and alignment jigs. Vehicle lifts enable efficient repairs. They elevate the car, giving easy access to its undercarriage. This reduces the strain on technicians while increasing productivity.

Proper storage solutions are vital. Tool storage racks keep your workspace organized. A cluttered environment may lead to accidents. Having a designated space for each tool saves time and frustration.

Consider the layout of your workshop when choosing fixtures. Not every fixture fits every space. Some areas might feel cramped with large equipment. This limits movement and efficiency. Ensuring you have enough space around each fixture is important. Always prioritize safety and usability. Choosing the right automotive fixtures enhances workflow and boosts morale.

When choosing automotive fixtures for your workshop, several factors come into play. The size of the fixtures must match your space. Consider how many vehicles you usually handle. This affects the type of lifts or jigs you might need. Compact fixtures are often useful in smaller shops. Yet, larger ones can accommodate more complex tasks.

Durability is a crucial factor as well. Fixtures should withstand daily wear and tear. Look for materials that resist corrosion and damage. This often means spending more upfront. However, it can save money in the long run due to fewer replacements. Comfort is another aspect. Workers need ergonomically designed fixtures to prevent injuries. It’s easy to overlook this, but a comfortable workspace can boost productivity.

It's also important to evaluate the flexibility of your fixtures. Many workshops encounter diverse tasks. Adjustable fixtures might be necessary to adapt to various vehicle types. Reflect on your specific needs and the types of jobs you handle most. Investing in the right fixtures will enhance your workflow. If not carefully chosen, you may find them becoming hindrances rather than help. Consider these factors before making any decisions.

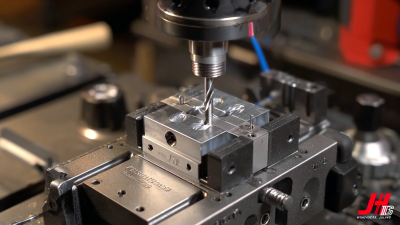

Choosing the right automotive fixtures for your workshop can feel overwhelming. Material quality is crucial. Fixtures made from high-grade steel or aluminum offer long-lasting strength. These materials resist wear and tear effectively. Consider the specific needs of your projects. A fixture that bends easily won’t serve you well.

Durability matters when facing frequent use. Plastic components may seem appealing for their lightweight nature, but they often lack strength. A cracked fixture interrupts your workflow. Look for robust designs that can handle heavy loads. Testing fixture performance before purchase can be wise.

Think about the environmental factors too. Will your fixtures withstand humidity or temperature changes? Corrosion-resistant materials can help here. Reflect on your needs. Poor choices may lead to costly repairs or replacements down the road. A little research can make a big difference.

When setting up your automotive workshop, space optimization is key. Efficient use of space can lead to better workflow and increased productivity. Start by assessing your available area. Measure your workshop dimensions carefully. Consider not just workbenches but also tool storage and vehicle access.

Implement vertical storage solutions. Wall-mounted racks can save floor space. Hanging tools can keep them within reach but out of the way. Adjustable shelving can adapt to changing needs. It is essential to arrange fixtures in a way that minimizes movement. The layout should allow smooth movement of tools and vehicles.

Evaluate your current setup regularly. Identify areas that feel cramped or inefficient. Be open to making changes. Sometimes, what seemed like a good arrangement may not work in practice. Remember, the goal is to create a space that not only functions well but also feels comfortable for you and your team.

| Fixture Type | Purpose | Material | Dimensions | Weight Capacity | Cost Range |

|---|---|---|---|---|---|

| Engine Hoist | Lift Engines | Steel | 72"x40"x20" | 2000 lbs | $250 - $600 |

| Workbench | Repair & Assembly | Wood/Metal | 60"x30"x36" | 500 lbs | $150 - $400 |

| Tire Rack | Store Tires | Metal | 48"x24"x72" | 1000 lbs | $100 - $250 |

| Tool Cabinet | Organize Tools | Steel | 36"x18"x72" | 300 lbs | $200 - $600 |

| Parts Washer | Clean Parts | Metal/Plastic | 36"x24"x36" | Variable | $150 - $400 |

When budgeting for automotive fixtures, focus on cost-effective solutions. Research shows that 70% of workshop owners aim to maximize their budget. Prioritizing essential tools is key. Consider fixtures like lifts and workbenches that enhance efficiency. According to industry reports, investing in durable fixtures can save up to 30% in long-term costs.

Choosing affordable materials may seem wise but can lead to drawbacks. Low-quality fixtures break down faster, leading to increased repair costs. A survey revealed that 60% of shops faced delays due to faulty equipment. Understanding the trade-off between initial cost and longevity is crucial.

Explore secondhand options or local sourcing. Many workshops benefit from buying refurbished fixtures. This approach can cut costs by up to 40%. Still, inspect these items thoroughly to avoid poor-quality purchases. Finding a balance between price and reliability will ensure your workshop remains productive.