In today's highly competitive automotive industry, ensuring precision and quality in manufacturing processes is paramount. One essential tool in achieving this objective is the "Car Checking Fixture." This specialized equipment plays a crucial role in the inspection and verification of automotive components, allowing manufacturers to identify and rectify any discrepancies early in the production cycle.

By effectively utilizing Car Checking Fixtures, automotive professionals can enhance the accuracy of their measurements, reduce the likelihood of errors, and ultimately improve the overall performance of their vehicles. This guide aims to provide practical insights and strategies for leveraging Car Checking Fixtures to their fullest potential, ensuring that every component meets the highest standards of quality and consistency.

Through a comprehensive understanding of their applications and best practices, manufacturers can foster greater efficiency and reliability in their production processes, leading to higher customer satisfaction and a stronger market position.

Car checking fixtures play a crucial role in vehicle maintenance, serving as essential tools for ensuring optimal performance. These fixtures are designed to accurately assess various components of a vehicle, including alignment, suspension, and structural integrity. By utilizing these specialized tools, automotive professionals can identify issues that may not be immediately observable through regular inspections. Consequently, this proactive approach helps in preventing potential problems, thereby enhancing the vehicle's longevity and reliability.

Understanding the importance of car checking fixtures goes beyond mere functionality; it underscores the need for precision in maintaining vehicles. Regular use of these fixtures allows for systematic checks, contributing to a thorough understanding of a car's performance metrics. This data-driven approach enables mechanics to provide informed recommendations to vehicle owners, ensuring that any required maintenance or repairs are conducted before they escalate into major issues. Ultimately, the incorporation of car checking fixtures into regular maintenance routines not only optimizes vehicle performance but also fosters a culture of safety and efficiency in automotive care.

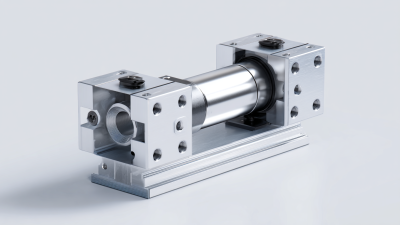

When selecting car checking fixtures, several key features ensure optimal performance and accuracy in automotive assessments. First and foremost, durability is vital. Fixtures should be constructed from high-quality materials that can withstand the rigors of repeated use, including extreme temperatures and physical stresses. This ensures longevity and reliability, allowing for consistent performance over time.

Another important feature is versatility. Effective car checking fixtures should be adjustable to accommodate various vehicle types and sizes. This flexibility allows technicians to perform thorough inspections without the need for multiple specialized fixtures. Moreover, precise alignment and measuring capabilities are crucial; fixtures should facilitate exact placement of components to guarantee accurate readings and assessments. This precision not only enhances the quality of the work but also contributes to the overall efficiency of the checking process.

Additionally, user-friendly design cannot be overlooked. Fixtures should be easy to set up and operate, minimizing training time for technicians and maximizing productivity. Integration with digital measurement tools can further streamline the process, providing real-time data analysis and improving decision-making capabilities. By focusing on these key features, automotive professionals can leverage car checking fixtures to achieve superior performance and maintain high standards of quality in vehicle inspections.

Setting up car checking fixtures effectively is crucial for ensuring that vehicles meet stringent performance standards. According to a report by McKinsey & Company, automakers that integrate advanced inspection technologies can reduce production costs by up to 20% and improve overall product quality by 30%. The first step in utilizing these fixtures is to establish a standardized inspection procedure tailored to the specific requirements of the vehicle components being tested. This may involve detailed schematics and specifications, along with a well-defined checklist for every part that needs affirmation of quality.

Setting up car checking fixtures effectively is crucial for ensuring that vehicles meet stringent performance standards. According to a report by McKinsey & Company, automakers that integrate advanced inspection technologies can reduce production costs by up to 20% and improve overall product quality by 30%. The first step in utilizing these fixtures is to establish a standardized inspection procedure tailored to the specific requirements of the vehicle components being tested. This may involve detailed schematics and specifications, along with a well-defined checklist for every part that needs affirmation of quality.

Once the procedures are in place, it’s vital to incorporate the right technology. Implementing digital measuring systems can provide real-time data analytics, allowing manufacturers to identify performance discrepancies as they arise. A report from Deloitte indicates that 63% of automotive firms are adopting such technology to enhance operational efficiency. Additionally, training staff on the use of these fixtures and technologies ensures accurate readings and reduces the likelihood of errors during inspections. Overall, a systematic approach in setting up car checking fixtures not only promotes optimal vehicle performance but also aligns with industry best practices, leading to reduced rework and enhanced customer satisfaction.

When utilizing car checking fixtures, it's crucial to avoid common pitfalls that can lead to suboptimal performance. One significant mistake is neglecting regular calibration. According to a report from the Automotive Quality Institute, improperly calibrated fixtures can result in measurement errors of up to 15%, which can severely impact quality control. Regular checks and adjustments not only ensure accuracy but also prolong the lifespan of the fixtures, ultimately saving costs in the long run.

Another frequent error is poor fixture design, which can limit accessibility or create difficulties in the checking process. The International Society of Automotive Engineers highlights that over 30% of production delays are linked to inadequate fixture design. By investing time in developing user-friendly designs that facilitate easy access to critical measurements, manufacturers can enhance operational efficiency. Furthermore, training personnel on these fixtures is essential; a study from the Automotive Research Council found that effective training can reduce error rates by up to 20%, significantly improving overall performance in quality assurance processes.

Maintaining and storing car checking fixtures properly is crucial for ensuring their longevity and accuracy. First, regular cleaning routines should be established. Fixtures should be cleaned after each use to remove any residual debris or contaminants that could affect their performance in future checks. Using non-corrosive cleaning agents and a soft cloth can prevent damage while ensuring that the fixtures remain in optimal condition.

In addition to cleaning, storage plays a vital role in the maintenance of car checking fixtures. It is advisable to store them in a controlled environment, away from extreme temperatures and humidity levels that could warp or deteriorate materials. Utilizing dedicated storage solutions, such as foam-lined cases or cabinets, can help prevent accidental damage and ensure that fixtures are organized and easily accessible. Moreover, it’s beneficial to keep a log of usage and maintenance to help track the condition of the fixtures over time, allowing for timely repairs or replacements when necessary.

This chart displays key performance metrics for car checking fixtures, including accuracy, durability, setup time, and calibration frequency. These metrics are crucial for maintaining optimal performance and ensuring efficient use of car checking fixtures.