In today's competitive manufacturing landscape, the role of die casters has become increasingly vital. Die casters are not only crucial for producing complex shapes and designs but also play a significant role in optimizing manufacturing efficiency. According to a report by the Global Die Casting Market Analysis, the die casting industry is projected to reach $85.5 billion by 2024, underlining its importance in various sectors including automotive, aerospace, and consumer goods. This rapid growth reflects a higher demand for lightweight and durable materials, which die casting readily provides.

The efficiency of manufacturing processes is directly tied to the technology and methods employed, and die casters are at the forefront of this advancement. They enable faster production cycles and reduce material waste, aligning with sustainability goals. A survey conducted by the Metal Working Industry Association highlighted that companies utilizing die casting techniques reported a 15-20% increase in production speed compared to traditional methods. This not only contributes to cost savings but also enhances product quality, a key factor for customer satisfaction in today's market.

Furthermore, as industries increasingly pivot towards automation and smart manufacturing, die casters are evolving to incorporate innovative technologies that enhance precision and reliability. With digital transformations reshaping manufacturing processes, the integration of die casting in production lines positions companies to achieve operational excellence and meet the evolving demands of the global market.

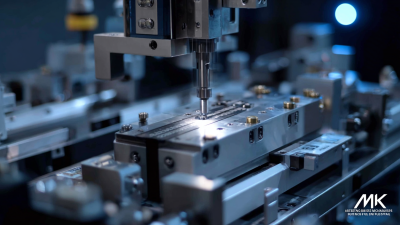

Die casting has emerged as a pivotal solution for manufacturers aiming to streamline their production workflows. By utilizing this process, companies can produce complex geometries with high precision, significantly reducing the material waste typically associated with traditional manufacturing techniques. The efficiency of die casting allows for quicker turnaround times, which is essential in today’s fast-paced market where speed to market can define competitive advantage.

Moreover, advancements in technology, such as additive manufacturing, have further enhanced the die casting process, enabling manufacturers to create intricate patterns and components that were once deemed impossible. This synergy not only minimizes production costs but also enriches the overall quality of end products. As industries continue to evolve and embrace innovative strategies, integrating die casting into manufacturing workflows will be crucial in driving efficiency and maintaining a strong market presence.

Die casting plays a pivotal role in modern manufacturing, particularly in enhancing productivity and quality. One of the primary advantages of die casters is their ability to produce complex shapes and intricate designs with remarkable precision. This capability allows manufacturers to create components that meet stringent specifications, ultimately reducing the need for extensive post-processing. As a result, products can reach the market faster, aligning with the demand for quick turnarounds in today’s competitive landscape.

Moreover, die casters contribute to improved material efficiency. By utilizing high-pressure techniques, these systems maximize the use of raw materials, reducing waste significantly. This not only lowers production costs but also aligns with environmentally sustainable practices, offering manufacturers a way to minimize their ecological footprint. Furthermore, the durability and strength of die-cast components ensure higher quality standards, enhancing the overall integrity of the final product. These advantages position die casters as essential tools in the manufacturing process, driving both operational efficiency and superior product outcomes.

The integration of die casting technology in manufacturing processes significantly enhances cost-efficiency. Die casting allows for the production of high volumes of complex parts at a lower cost compared to traditional manufacturing methods. This is primarily due to the minimal waste generated during the die casting process, as the materials can be reused and are precisely molded, reducing the need for extensive machining or finishing. The speed of production also plays a crucial role; die casting can output parts quickly, thus lowering labor costs and increasing overall productivity.

Moreover, die casting is ideal for producing parts with tight tolerances and excellent surface finish, which reduces the need for secondary operations. Consequently, manufacturers can achieve higher quality with less investment in rework or scrapped materials. The durability of components produced through die casting also means that firms can benefit from longer product life cycles, leading to reduced replacement costs and enhanced customer satisfaction. By adopting die casting technology, manufacturers can streamline their operations and achieve significant savings, making it a vital component in modern efficient manufacturing.

| Aspect | Benefits | Examples |

|---|---|---|

| Material Efficiency | Minimizes scrap and waste | Reduction of material costs by up to 25% |

| Production Speed | Fast cycle times | Parts produced in seconds |

| Design Flexibility | Complex shapes can be cast | Improved product designs with less assembly |

| Durability | Strong and reliable components | Longer product lifespan |

| Labor Costs | Lower labor requirements | Reduced operational costs |

Die casting has emerged as a transformative manufacturing process across various industries, offering innovative applications that enhance efficiency and precision. In sectors such as automotive, aerospace, and electronics, die casting enables the production of complex and lightweight components that meet stringent quality standards. The ability to create intricate shapes with tight tolerances reduces the need for extensive machining, leading to faster production cycles and cost savings. As industries strive for greater mechanization and reduced lead times, the adoption of die casting technology becomes increasingly essential.

Moreover, the versatility of die casting is being recognized in modern applications beyond traditional sectors. Industries are now leveraging die casting for advanced consumer products, medical devices, and even components in renewable energy technologies. The integration of smart technologies into die casting processes, such as automation and real-time monitoring, further propels innovation. This evolution reflects a broader trend in manufacturing as companies seek solutions that not only streamline production but also improve product performance and sustainability. The future of die casting appears promising, with continuous advancements paving the way for more efficient and diverse applications in manufacturing.

As the manufacturing landscape continues to evolve, die casting stands at the forefront of technology with trends that significantly enhance manufacturing efficiency. According to a recent report by MarketsandMarkets, the global die casting market is expected to reach $80.09 billion by 2026, growing at a CAGR of 8.3% from 2021. This growth is largely driven by advancements in automation and the increasing demand for lightweight components in industries such as automotive and aerospace. These innovations are essential for reducing waste and facilitating faster production times, ultimately lowering costs and maximizing output.

Additionally, the integration of Industry 4.0 technologies, including the Internet of Things (IoT) and artificial intelligence, is transforming die casting processes. A study by the International Journal of Advanced Manufacturing Technology indicates that manufacturers employing smart technologies in die casting setups can enhance their operational efficiency by up to 30%. Predictive maintenance powered by AI not only minimizes downtime but also optimizes the energy consumption of die casting machines, which is crucial in an era where manufacturers are looking to meet sustainability goals. As the industry embraces these trends, the role of die casting will only become more essential in driving efficiency and maintaining competitive advantage in the manufacturing sector.